The Landscape of Economical Brick Making Machinery

Defining the “Affordable” Segment

The term “affordable” in this context does not equate to low quality or compromised utility. Instead, it signifies a segment of the machinery market that prioritizes intelligent design, efficient production processes, and economies of scale to deliver exceptional value. These machines are engineered to perform core functions with high reliability, often streamlining advanced automation in favor of robust semi-automatic or fully manual operation that reduces complexity and cost. They target small to medium-scale entrepreneurs, local construction projects, and markets where the initial capital outlay is a critical decision factor. For the distributor, this means a product with a wider, more accessible target customer base and faster inventory turnover.

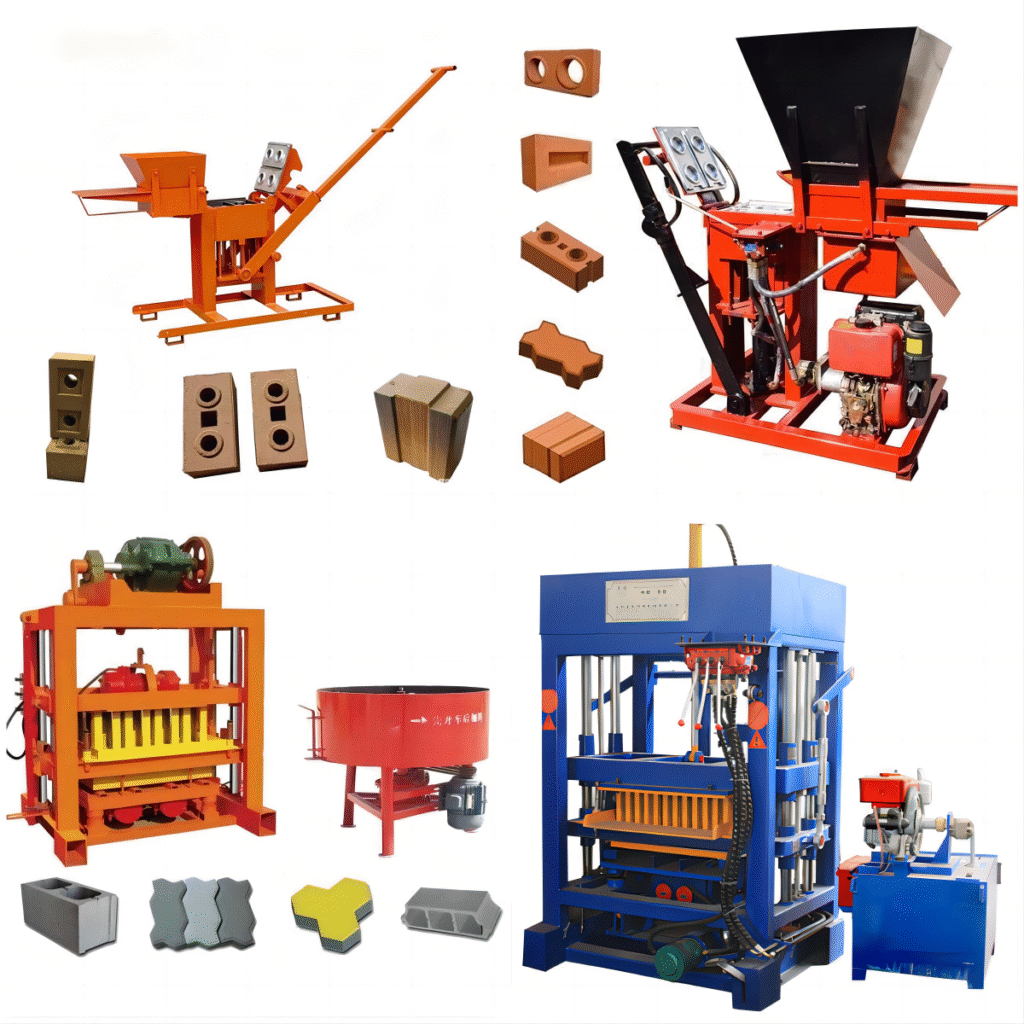

Core Technologies and Machine Typologies

The affordable machinery segment encompasses a diverse range of technologies, each suited to different raw materials and production scales.

- Manual and Semi-Automatic Presses: These are the bedrock of low-cost, high-value entry into brick manufacturing. They require more manual labor for feeding and unloading but utilize a powerful mechanical or hydraulic press to form bricks with high density and uniformity. They are incredibly versatile, capable of producing solid, hollow, and interlocking bricks from various materials.

- Hydraulic Block Forming Machines: A step up in automation, these machines use sustained hydraulic pressure to compact raw material into molds. This results in bricks and blocks of superior strength and consistency. Affordable models in this range often feature programmable logic controllers (PLCs) for basic operations, enhancing output with moderate investment.

- Mobile Brick Making Machines: A uniquely valuable category, these compact, often trailer-mounted units can be transported directly to construction sites. They utilize locally available soil or other aggregates to produce bricks on-demand, eliminating transport costs for the end-user. This model presents a highly attractive “business-in-a-box” solution for dealers to offer their clients.

- Raw Material Flexibility: A key strength of these machines is their adaptability. They are designed to work with:

- Clay: Traditional material, often fired in kilns.

- Concrete: A mixture of cement, sand, and aggregate, cured by hydration.

- Fly Ash: An eco-friendly alternative using industrial by-product, contributing to sustainable construction.

- Compressed Earth: Stabilized with a small amount of cement, ideal for low-cost housing.

Strategic Advantages for Distributors and Procurement Agents

High Margin Potential with Competitive Pricing

The primary advantage is the significant margin structure enabled by competitive factory pricing. Sourcing directly from manufacturers allows intermediaries to maintain healthy profits while still offering market-beating prices to their downstream clients. This price advantage is a powerful tool for market penetration and competition.

Addressing a Massive and Growing Market Demand

Urbanization, infrastructure development, and the need for affordable housing across emerging economies create an insatiable demand for basic building materials. Affordable machinery empowers local entrepreneurs to meet this demand, creating a virtuous cycle. As a distributor, you are supplying the very tool that fuels this sector.

Low Barrier to Entry for End-Clients, Expanding Your Customer Base

By offering machinery that requires a manageable initial investment, you effectively expand your potential clientele from large industrial players to include individual entrepreneurs, community cooperatives, and small construction firms. This diversification mitigates business risk.

After-Sales Services as a Revenue Stream

The machinery relationship does not end at the sale. Providing spare parts, wear parts (like molds and pallets), technical support, and maintenance contracts creates a recurring revenue stream and strengthens client loyalty. Building a reputation for reliable after-sales support is a critical differentiator.

Navigating the Procurement Process: A Guide for B2B Buyers

Identifying Reputable Manufacturers

Due diligence is crucial. Beyond online portals, consider visiting major industrial exhibitions in China focused on construction machinery. Verify business licenses, inspect factory audit reports, and prioritize manufacturers with a track record of exporting to your target regions. Request and contact references from existing international clients.

Critical Technical and Commercial Evaluation Points

- Production Capacity & Cycle Time: Understand output in bricks per hour/day under standard conditions.

- Power Requirements: Ensure the machine’s specifications match the common voltage and phase in your target market.

- Build Quality & Key Components: Inspect the quality of steel, the robustness of the hydraulic system, and the brand reputation of critical components like pumps and PLCs, even in affordable models.

- Mold Customization: The ability to supply or customize molds for different block sizes and designs adds tremendous value to your offering.

- Packaging for Export: Ensure the supplier has experience in export-standard packaging (wooden crates, seaworthy) to prevent transit damage.

- Payment Terms and Minimum Order Quantity (MOQ): Negotiate terms that balance risk and cash flow. Start with smaller orders to validate quality before scaling up.

The Importance of Comprehensive Supplier Agreements

A clear contract should cover technical specifications, delivery timelines (Incoterms), payment schedules, warranty terms (typically 12-18 months for core parts), and protocols for handling defective goods. Intellectual property rights for any custom designs should also be clarified.

Conclusion

The sector of affordably priced brick manufacturing machinery from China presents a formidable and timely opportunity for distributors, dealers, and global procurement agents. It is a segment defined not by compromise, but by strategic value engineering, delivering the essential reliability and productivity needed to activate small and medium enterprises worldwide. By understanding the technology spectrum, recognizing the vast addressable market, and mastering the intricacies of selective sourcing and partnership building, intermediaries can build a highly profitable and impactful business line. Success in this field hinges on moving beyond a simple import-export model to becoming a value-added partner, providing not just equipment, but complete solutions encompassing machine selection, technical support, and parts supply. In doing so, you position your business at the forefront of empowering local construction industries and contributing to global infrastructure development.

FAQ

Q1: What is the typical price range for an affordable brick-making machine from China?

Prices vary significantly based on type, automation level, and output. Small manual machines can start from a few thousand dollars, semi-automatic hydraulic presses may range from $10,000 to $30,000, and more advanced stationary hydraulic lines can be $40,000 to $80,000. Accurate pricing requires specifying output capacity and configuration.

Q2: How do I ensure the machine quality without a physical pre-shipment inspection?

Always request a Factory Acceptance Test (FAT) conducted via live video stream. Reputable suppliers will demonstrate the machine’s operation, test its functions, and allow you to verify the production of sample bricks remotely. Third-party inspection services are also a valuable option for larger orders.

Q3: What are the common challenges with installation and commissioning, and how are they addressed?

Challenges can include incorrect assembly, electrical connection issues, or parameter setting errors. Reliable suppliers provide detailed installation manuals, video guides, and remote video support via platforms like Zoom or WhatsApp. For complex lines, on-site technician dispatch can be negotiated, though it adds to cost.

Q4: What is the lead time for orders, and what shipping methods are used?

Lead times range from 15-30 days for standard models to 45-90 days for customized or high-capacity lines. Shipping is typically via sea freight (LCL or FCL) for the machine and air freight for urgent spare parts. The supplier should handle export formalities and provide all necessary shipping documents.

Q5: How vital is mold availability and customization?

Molds are consumable parts and a critical source of recurring revenue. Partnering with a supplier who can quickly provide high-quality, durable replacement molds and offer customization for local block specifications is a major competitive advantage. Ensure they have in-house mold design and manufacturing capability.

Q6: What after-sales support should I expect from the manufacturer?

Minimum support includes comprehensive operation and maintenance manuals, electrical diagrams, and a parts catalog. Expect a warranty (e.g., 12 months for core components) and access to technical support for troubleshooting. Clarify response times for support queries and the availability of a readily accessible spare parts inventory.