The global construction sector is perpetually driven by the demand for reliable, efficient, and cost-effective building materials. Central to this industry is the humble brick, a fundamental component whose method of production has been revolutionized by advanced machinery. For distributors, dealers, and procurement specialists, understanding the intricacies of this equipment is not just a technical exercise but a critical business imperative.

A Detailed Examination of Brick Manufacturing Systems

1.1 The Fundamental Manufacturing Process: From Raw Material to Finished Product

The operation of a brick manufacturing system is a symphony of precision engineering and material science. It transforms basic raw materials into standardized, high-strength construction units through a meticulously orchestrated process.

- Precision Material Preparation and Homogenization: The journey begins with the careful selection and proportioning of raw materials. The primary mixture typically consists of cement, various aggregates (such as sand, stone dust, or fly ash), and water. The ratio of these components is paramount, dictating the final product’s strength, texture, and durability. In advanced systems, automated weigh feeders ensure batch-to-batch consistency. The mixing process is not merely about combining ingredients but about achieving a homogenous, semi-dry consistency where every particle of cement is uniformly coated with the aggregate, and moisture is evenly distributed. This homogeneity is the first and most crucial step toward producing a brick with consistent structural properties.

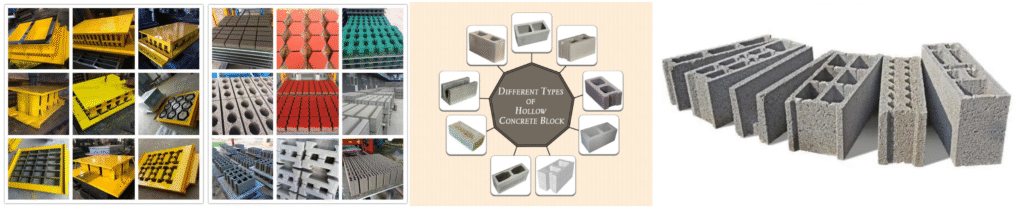

- The Critical Phase of Mold Filling and Densification: The prepared mixture is then transferred into the mold cavity. The design and precision of this mold are what define the brick’s final shape, whether it be a standard rectangular block, a hollow core design for insulation, or an intricately patterned paving stone. In sophisticated apparatuses, the filling mechanism ensures an even distribution of material throughout the mold, preventing inconsistencies in density. Following filling, the system applies immense mechanical or hydraulic pressure. This action is not merely compression; it is a process of densification that forcibly expels entrapped air, aligns the particulate matter, and initiates the initial bonding process, resulting in a “green” brick with sufficient integrity to be handled.

- Curing for Ultimate Strength Development and Final Processing: Once ejected from the mold, the green brick possesses its shape but not its full strength. The curing process is where it gains its structural prowess. This can be achieved through two primary methods. The first is static curing, where bricks are stacked and covered with curing sheets or placed in a chamber where controlled temperature and humidity are maintained for a specific duration, allowing for complete cement hydration. The second, used in some high-output systems, is steam curing in autoclaves, which accelerates the strength gain significantly. After curing, the hardened units are automatically sorted, counted, and stacked onto pallets by robotic arms or conveyor-based systems, ready for wrapping, storage, and shipment.

1.2 A Taxonomy of Production Systems: Matching Technology to Market Need

Brick production systems are categorized based on their operational methodology and degree of automation, each serving a distinct segment of the market.

- Fully Integrated Production Lines: These are the apex predators of brick manufacturing, designed for massive, uninterrupted output. They are characterized by a seamless, closed-loop process where raw material input, mixing, molding, curing, and palletizing are all interconnected and managed by a central computerized control system. Human intervention is primarily limited to monitoring, maintenance, and programming. These lines are the optimal choice for supplying large-scale infrastructure projects, national distributors, and markets where volume and consistent quality are non-negotiable.

- Cycle-Oriented Production Units: This category represents a robust middle ground, offering high automation in the core compaction process while requiring manual assistance for peripheral tasks. The machine itself performs the pressing and molding cycles automatically, but operators may be needed to feed raw material into the hopper or transfer the freshly molded bricks to the curing area. This configuration delivers an excellent balance, providing high production capacity and remarkable quality consistency at a capital investment significantly lower than a fully integrated line, making it ideal for growing businesses and regional suppliers.

- Manual Compression Systems: These are the most accessible and versatile units, often characterized by their portability and simplicity. Operation is fundamentally manual: an operator fills the mold box, engages a lever or a small hydraulic pump to apply pressure, and then releases the formed brick directly onto the ground or a pallet. While their output per hour is the lowest and they are labor-dependent, their low cost, minimal maintenance, and ability to be deployed on-site with minimal infrastructure make them a powerful tool for small entrepreneurs, community-based projects, and specialized, low-volume production runs.

1.3 Beyond Output: Evaluating Key Performance and Product Parameters

For a commercial buyer, the assessment of a machine goes beyond its brochure specifications. It involves a holistic view of its performance and the quality of the product it yields.

- Output Capacity and Operational Rhythm: The bricks-per-hour figure must be understood in the context of the entire production cycle, including curing time. A machine’s true capacity is its sustained output over an 8-hour or 24-hour shift, not just a peak theoretical number.

- Dimensional Accuracy and Surface Finish: The precision of the mold and the consistency of the pressure application directly impact the brick’s dimensional tolerances and surface quality. High-quality apparatuses produce bricks with sharp edges, smooth surfaces, and uniform dimensions, which simplifies bricklaying and reduces mortar usage.

- Versatility in Raw Material Formulation: A significant advantage of modern systems is their ability to function effectively with a wide range of raw material mixes. This includes the ability to incorporate industrial by-products like slag or fly ash, which can reduce material costs and enhance the product’s environmental profile.

- Durability and Serviceability of the Apparatus: The machine’s construction quality, the grade of steel used in the frame and mold, and the reliability of its hydraulic and control systems determine its operational lifespan and total cost of ownership. Easy access for maintenance and the widespread availability of common spare parts are critical logistical considerations.

1.4 The Strategic Business Case for Advanced Manufacturing Technology

Investing in a modern brick production system is a strategic decision that confers multiple layers of competitive advantage.

- Unmatched Economic Efficiency and Scalability: Automation slashes the per-unit cost of production by maximizing output and minimizing direct labor. This creates a scalable business model where increasing volume does not necessitate a linear increase in operational costs, leading to higher profit margins.

- Guaranteed Product Consistency and Adherence to Standards: Machine-made bricks are uniform. This consistency is vital for builders, as it ensures predictable performance, simplifies construction processes, and guarantees compliance with national and international building codes, a key selling point for discerning clients.

- Empowerment through Product Diversification: With a library of interchangeable molds, a single investment can yield a diverse product catalog. A supplier can quickly switch from producing standard construction bricks to decorative pavers, retaining wall blocks, or specialized landscaping products, allowing them to capture multiple market segments and respond agilely to trends.

- Enhancement of Sustainability Credentials: The controlled production process significantly reduces material waste compared to traditional methods. Furthermore, the ability to use recycled aggregates and supplementary cementitious materials allows businesses to market a “greener” product, appealing to a growing segment of environmentally conscious contractors and developers.

1.5 A Procurement Framework for Commercial Stakeholders

Navigating the procurement process requires a disciplined, strategic approach focused on long-term value.

- Conducting a Comprehensive Market and Feasibility Analysis: Before selecting a machine, one must have a deep understanding of the local demand—preferred brick types, quality expectations, and price sensitivity. The chosen technology must be a precise fit for this market reality.

- Performing a Rigorous Total Cost of Ownership (TCO) Analysis: The purchase price is just the initial outlay. A prudent buyer will model all ongoing costs: energy consumption, labor, preventive maintenance, spare parts, and the cost of capital. This TCO model provides a true picture of the investment’s profitability.

- Vetting the Equipment Provider’s Support Ecosystem: The machine’s value is heavily dependent on the supplier’s support. Key questions must be asked: What is their lead time for critical spare parts? Do they offer comprehensive operator training? Is technical support readily accessible? A machine without reliable support is a liability.

- Validating Machine Performance and Compliance: Insist on seeing the machine in operation, preferably under conditions similar to your own. Request certification of compliance with relevant international safety and performance standards. This due diligence mitigates risk and ensures the equipment is fit for its intended purpose.

Conclusión

The technology behind brick manufacturing represents a mature yet continuously evolving field. For distributors and procurement experts, the selection of appropriate machinery is a cornerstone decision that directly impacts market relevance, operational efficiency, and long-term profitability. The spectrum of available systems—from highly automated production lines to versatile manual presses—ensures that there is a technological solution for every business model and market tier. Success in this arena is not merely about purchasing a machine; it is about strategically investing in a production capability that delivers consistent quality, enables product diversification, and builds a formidable reputation for reliability. In the competitive global construction supply chain, mastery over this technology is synonymous with a sustainable competitive edge.

Frequently Asked Questions (FAQ)

Q1: How does the final product from an automated system differ from one produced by a manual machine?

A: While both can produce structurally sound bricks, the key differences lie in consistency and finish. Automated systems produce bricks with exceptional dimensional uniformity, consistent density, and superior surface finish across thousands of units. Manual machines, while capable, may exhibit slight variations in size, density, and texture from one brick to the next due to the inherent variability in human-operated processes.

Q2: What is the typical lead time from procurement to full operational deployment for a semi-automatic system?

A: Lead times can vary significantly based on the complexity of the system and the manufacturer’s schedule. Generally, for a semi-automatic unit, expect a period of 4 to 8 weeks for manufacturing and shipping. On-site installation, foundation preparation, and operator training can add an additional 1 to 3 weeks before the system is fully operational and producing saleable bricks.

Q3: Can these systems be customized to produce unique or proprietary brick designs?

A: Absolutely. The primary method for defining a brick’s shape is the mold. Reputable equipment providers often offer custom mold design and fabrication services. This allows clients to produce unique, patented brick designs, specialty shapes for architectural projects, or products tailored to specific regional preferences.

Q4: What are the most common maintenance requirements, and what is their typical frequency?

A: Regular maintenance is crucial for longevity. Common tasks include:

- Daily: Cleaning of the mold and hopper, visual inspection for leaks or wear.

- Weekly: Checking and tightening of bolts and nuts, inspecting hydraulic hoses.

- Monthly: Changing hydraulic oil filters, checking and calibrating pressure sensors.

- Annually: A comprehensive inspection of the hydraulic system, electrical components, and structural frame.

Q5: How critical is the quality of raw materials to the machine’s performance and output quality?

A: It is fundamentally critical. The machine is designed to process specific types and sizes of aggregates. Using poorly graded sand, contaminated materials, or an incorrect water-cement ratio can lead to production issues like mold sticking, poor compaction, and low-strength bricks. Consistent, high-quality raw materials are a prerequisite for achieving the machine’s advertised performance and product quality.

Q6: What are the primary power requirements for operating a medium-capacity automated unit?

A: Most medium-to-large industrial units require a three-phase electrical power supply, typically at 380V-440V, with a significant power draw (e.g., 20-50 kW depending on the model). It is essential to have a stable power source and the necessary electrical infrastructure in place. Some systems can also be configured with optional diesel power units for locations with unreliable grid electricity.

根据laying brick machine这个标题帮我写一篇文章,用英语,介绍,正文,结论,FAQ,正文要在1500个单词以上, 介绍,正文,结论,faq 不能出现别的品牌词,受众群体是经销商,分销商,采购商等,用英文,一级标题,二级标题,三级标题等格式要正确,文章所有内容要和之前的写出来的文章不一样,我给出的标题就不用在开头写了。

Guía Integral de Máquinas para Colocar Ladrillos: Fortaleciendo el Emprendimiento en Construcción a Pequeña Escala

Introduction to Mobile Brick Manufacturing Technology

In the evolving landscape of global construction, accessibility and operational flexibility have become as valuable as sheer production volume. Enter the laying brick machine, a category of equipment distinct from large-scale stationary plants, designed for on-site production and decentralized manufacturing models. This machinery, characterized by its portability and straightforward operation, represents a significant market opportunity for distributors targeting small to medium enterprises (SMEs), rural developers, and community-focused construction projects. This article provides an in-depth exploration of the laying brick machine, examining its unique operational mechanics, market applications, economic advantages, and the strategic considerations for dealers and procurement professionals. The focus remains exclusively on the technological and commercial aspects of this specific machine type, offering a fresh perspective for business-to-business stakeholders.

An In-Depth Analysis of Laying Brick Machine Technology

1.1 Core Operational Mechanism and Distinguishing Features

Unlike its fully automated counterparts, the laying brick machine operates on a principle of localized, batch-by-batch production. Its defining characteristic is its mobility; the entire unit can be easily relocated across a job site or to a new project location, often without requiring disassembly.

- The “Laying” Process Demystified: The term “laying” is literal. The machine is positioned on a leveled ground or a prepared concrete slab. The operator fills the mold chamber with the prepared concrete mixture. A mechanical lever or a compact hydraulic system is then engaged, applying significant pressure to compact the material. Once the brick is formed, the machine is lifted or wheeled away, “laying” the freshly molded, green brick directly onto the ground in its exact curing location. This eliminates the need for complex conveyor systems or palletizing robots.

- Simplified Material Handling and Workflow: The production workflow is linear and uncomplicated. Raw materials (cement, soil, or sand) are mixed in a central, often manual, pan mixer. The mixture is then transported to the machine’s location. The cycle of filling, compacting, and laying is repeated, with the machine moving backward in a straight line, leaving a trail of finished bricks behind it. This method drastically reduces the need for brick transportation before curing, streamlining the on-site workflow.

- Key Design Components: The machine’s architecture is robust yet simple. It typically consists of a heavy-duty steel frame, a precision-engineered mold box (often capable of producing multiple bricks per cycle), a compaction mechanism (manual, mechanical, or hydraulic), and a simple ejection system. The design prioritizes durability and ease of use over complex automation, resulting in a machine with a long operational lifespan and minimal maintenance points.

1.2 Market Positioning and Ideal Application Scenarios

The laying brick machine occupies a specific and vital niche in the construction ecosystem, catering to segments where large-scale plants are impractical or uneconomical.

- The Champion of Rural and Remote Construction: In areas with underdeveloped infrastructure or limited access to centralized brick suppliers, this machine enables local production. Communities can manufacture their own building materials using locally sourced soil or sand, empowering self-sufficiency and drastically reducing transportation costs.

- The Engine of Small-Scale Entrepreneurial Ventures: For individual entrepreneurs, the low capital investment required for a laying brick machine presents a compelling business opportunity. An individual can establish a small brick-making yard, producing bricks on demand for local homebuilders, fencing projects, and small commercial structures, creating a sustainable micro-enterprise.

- The Solution for On-Demand, On-Site Production: For construction projects where the exact number of bricks is uncertain or where just-in-time production is beneficial, this machine is ideal. It allows contractors to produce bricks directly on the construction site, ensuring a perfect match of brick batches for a single project and eliminating material waste and storage issues.

- Specialized Applications and Disaster Relief: Its portability makes it suitable for producing specialized bricks for landscaping, garden pathways, and small-scale infrastructure. Furthermore, in post-disaster reconstruction scenarios, these machines can be rapidly deployed to produce building materials locally, accelerating recovery efforts.

1.3 Strategic Advantages for Distributors and End-Users

The commercial appeal of the laying brick machine is built on a foundation of low barriers to entry and high operational flexibility.

- Minimal Initial Capital Outlay: This is the most significant advantage. The cost of a single laying brick machine is a fraction of that of a semi- or fully-automatic system, making it an accessible product for a vast segment of the market. For distributors, this means a larger potential customer base and faster sales cycles.

- Unmatched Operational Flexibility and Low Overhead: The machine does not require a dedicated factory shed or a permanent concrete foundation. It can operate in open spaces, requiring only a source of raw materials and a few square meters of level ground. This results in extremely low setup and overhead costs for the end-user.

- Reduced Reliance on Complex Logistics and Energy Grids: Since production is decentralized and the bricks are cured in place, the complex logistics of transporting fragile green bricks are eliminated. Furthermore, most models are entirely mechanical or use low-power hydraulics, making them suitable for operation in areas with unreliable or no electricity.

- Robust Construction and Ease of Maintenance: With fewer moving parts and no sophisticated electronics, these machines are inherently durable. Maintenance is straightforward, often requiring only basic tools and mechanical knowledge. This translates to high machine uptime, customer satisfaction, and a lower burden on the distributor’s after-sales service network.

1.4 Critical Technical and Commercial Evaluation Parameters

For a distributor or procurement manager, assessing the quality and suitability of a laying brick machine requires a focused set of criteria.

- Production Output and Cycle Time: Output is measured in bricks per day rather than per hour. A critical metric is the cycle time—how long it takes to produce one batch of bricks (e.g., 3-5 bricks) and reposition the machine. A faster cycle time directly increases daily yield.

- Build Quality and Material Specifications: The quality of the steel used in the frame and mold determines the machine’s longevity. The hardness and precision of the mold liners are crucial for producing bricks with consistent dimensions and smooth surfaces. A robust vibration system (if present) ensures proper compaction.

- Versatilidad en la Producción de Productos: Many modern laying-type machines come with interchangeable molds. A single base unit can potentially produce solid blocks, hollow blocks, and paving stones. This versatility increases the value proposition for the end-user, allowing them to serve diverse customer needs.

- Ergonomics and Operator Safety: The design should prioritize operator safety and ease of use. Features like ergonomic lever handles, safety guards on moving parts, and a design that minimizes strenuous lifting are important differentiators that reduce the risk of workplace injury and operator fatigue.

Conclusión

The laying brick machine is a testament to the principle that appropriate technology can be as transformative as high-tech solutions. It democratizes the production of construction materials, placing the capability to manufacture bricks directly into the hands of small entrepreneurs, rural communities, and pragmatic contractors. For distributors and B2B stakeholders, this segment represents a dynamic and resilient market less susceptible to the economic fluctuations that can affect large-scale industrial projects. By understanding the unique operational logic, target applications, and commercial drivers of the laying brick machine, businesses can effectively cultivate a valuable and growing customer base, providing them with the tools to build not just structures, but sustainable local economies.

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between a “laying” machine and a “stationary” block making machine?

A: The core difference lies in mobility and brick handling. A laying machine is mobile, compacting and then ejecting bricks directly onto the ground for curing. A stationary machine is fixed in place, requiring a system to transport the freshly molded (green) bricks to a separate curing area, often involving pallets, racks, or conveyor belts.

Q2: What is the typical production output a single operator can achieve with a manual laying machine?

A: Output is highly dependent on the operator’s efficiency and the machine’s cycle time. A skilled operator using a manual machine producing 3-4 bricks per cycle can typically manufacture between 500 and 1,000 bricks in an 8-hour workday. Hydraulically-assisted models can increase this output.

Q3: Are the bricks produced by these machines of sufficient quality for permanent residential construction?

A: Yes, provided the correct raw material mix and compaction pressure are used. The bricks must be properly cured, typically by keeping them moist and covered for a minimum of 7-14 days. It is recommended that sample bricks be tested for compressive strength at a local laboratory to ensure they meet regional building standards.

Q4: What kind of raw material mix is required for optimal performance?

A: These machines are versatile but work best with a semi-dry concrete mix. A common ratio is 1 part cement to 6-8 parts of a well-graded aggregate (such as a mix of sand and fine gravel). The mixture must have just enough moisture to hold its shape when compacted but not be wet or sloppy.

Q5: What does the typical after-sales support package for this category of machine include?

A: A comprehensive support package should include detailed operational manuals, a set of basic tools, and a starter kit of critical wear parts (like replacement mold liners or seals for hydraulic models). Additionally, suppliers should offer remote troubleshooting support and ready access to a catalog of spare parts.

Q6: Can these machines be easily exported and used in different international markets?

A: Absolutely. Their simple design, lack of dependency on specific voltage standards, and robust construction make them ideal for export. The main considerations are ensuring the accompanying documentation is in the local language and that the distributor has a clear understanding of the local demand for specific brick sizes and types to supply the correct molds.

根据adobe brick machine这个标题帮我写一篇文章,用英语,介绍,正文,结论,FAQ,正文要在1500个单词以上, 介绍,正文,结论,faq 不能出现别的品牌词,受众群体是经销商,分销商,采购商等,用英文,一级标题,二级标题,三级标题等格式要正确,文章所有内容要和之前的写出来的文章不一样,我给出的标题就不用在开头写了。

An In-Depth Exploration of Adobe Brick Manufacturing Technology

Introduction to Modern Earthen Construction Systems

The resurgence of interest in sustainable, eco-friendly, and thermally efficient building materials has brought adobe brick back into the spotlight of contemporary construction. Unlike conventional cement bricks, adobe utilizes a ancient yet effective formula of earth, clay, sand, and organic stabilizers, modernized through mechanized production. This article provides a comprehensive analysis of the adobe brick machine, a specialized apparatus designed to transform raw earth into standardized, high-quality building blocks. For distributors, dealers, and bulk purchasers, this technology represents an opportunity to access the growing green building market. We will examine the machine’s operational principles, its place in the modern construction supply chain, the distinct advantages of compressed earth blocks, and the critical commercial factors for successful market penetration, all presented from a strictly non-proprietary, technological standpoint.

Comprehensive Technical and Commercial Analysis of Adobe Brick Machinery

1.1 The Science and Process of Mechanized Adobe Production

The modern adobe brick machine elevates a traditional manual process to an industrial level, ensuring consistency, strength, and efficiency while maintaining the core ecological benefits of the material.

- Material Science and Soil Selection: The fundamental requirement for successful adobe production is appropriate soil. The ideal mix contains a balanced proportion of clay (which acts as the binder), sand (which provides skeletal strength and reduces shrinkage), and silt. Many machines are equipped with integrated soil screening mechanisms to remove oversized aggregates and organic matter. Stabilizers, such as a small percentage of cement or natural binders like plant fibers, can be added to the mix to enhance durability and water resistance.

- The Hydro-Mechanical Compaction Process: The core of the machine’s function is the application of high-pressure compaction to a precisely measured volume of moistened earth. The mixture must have optimal moisture content—typically between 10-15%—to allow for proper particle lubrication and cohesion under pressure. Using a hydraulic ram or a mechanical press, the machine exerts immense force, measured in tons, to densify the material. This process aligns the clay particles, eliminates air pockets, and creates a strong inter-particle bond, resulting in a “semi-stabilized” or “stabilized” brick straight from the mold.

- Distinctive Curing and Final Processing: Unlike cement bricks that require hydration-based curing, freshly extruded adobe bricks are very fragile and must be handled with care. They are typically ejected onto pallets or a leveled, shaded curing area. The curing process for adobe is primarily air-drying, which can take several weeks depending on climatic conditions. The bricks must be protected from rain and direct sunlight initially to prevent cracking from rapid drying. This low-energy curing process is a significant contributor to the material’s low embodied energy.

1.2 Classification of Machinery by Output and Automation

Adobe brick machines are categorized not just by automation, but also by their production methodology and the resulting brick quality.

- Máquinas Prensadoras Manuales: These are the most accessible and widely used type, particularly in developing economies and for community-led projects. They are hand-operated, using a lever system to generate the necessary compaction force. While output is lower (typically 200-500 bricks per day), they are inexpensive, entirely off-grid, portable, and require minimal maintenance. They produce high-quality bricks suitable for a wide range of single-story constructions.

- Motorized Hydraulic Presses: This category represents a significant step up in production capacity and consistency. An electric or diesel motor powers a hydraulic pump, which delivers consistent, high-pressure compaction with minimal operator effort. These stationary machines can produce 800 to 2,000 bricks per day and often feature interchangeable molds for different brick sizes and profiles. They are ideal for small to medium-sized enterprises (SMEs) aiming to commercialize adobe bricks.

- Fully Integrated Adobe Production Systems: At the industrial end of the spectrum, these systems incorporate a soil crusher, rotary screen, mixer, and a high-pressure press into a single, continuous production line. Controlled by a programmable logic controller (PLC), they offer the highest output (3,000+ bricks daily) and unparalleled product uniformity. This level of investment is targeted at serious commercial producers supplying large-scale eco-resorts, housing developments, and institutional projects.

1.3 The Compelling Value Proposition of Mechanized Adobe Bricks

The end-product of these machines offers a unique set of benefits that align with modern architectural and environmental priorities.

- Superior Thermal Mass and Energy Efficiency: Adobe bricks have a high thermal mass, meaning they absorb heat during the day and release it slowly at night. This natural temperature regulation significantly reduces the need for mechanical heating and cooling, leading to substantial energy savings over the building’s lifetime—a powerful selling point.

- Exceptional Environmental Credentials and Low Embodied Energy: The primary raw material is earth, often sourced on-site or locally, drastically reducing transportation emissions. The production process consumes a fraction of the energy required for fired bricks or cement blocks, and it generates virtually no industrial waste. This positions adobe as a leading material in green building certification programs.

- Natural Humidity Regulation and Fire Resistance: The porous nature of adobe allows it to absorb and release moisture from the air, helping to maintain healthy indoor humidity levels. Furthermore, being made of earth, the bricks are completely non-combustible and provide excellent fire resistance, enhancing building safety.

- Cultural Aesthetics and Market Appeal: The distinct, earthy appearance of adobe bricks carries a unique aesthetic appeal, often associated with biophilic design and vernacular architecture. This appeals to a niche market of homeowners, architects, and developers looking for projects with character and a natural feel.

1.4 Strategic Market Analysis and Deployment Scenarios

Understanding where and how this technology fits into the global construction market is key for distributors.

- Targeting the Green Building and Eco-Tourism Sectors: The most natural market is the rapidly growing green construction industry. This includes builders and developers specializing in sustainable homes, eco-lodges, wellness retreats, and educational centers seeking LEED or similar certifications.

- Addressing Affordable Housing and Self-Build Initiatives: Governments and NGOs involved in affordable housing are increasingly turning to earth-based construction for its low cost and job creation potential. Distributors can partner with such organizations to supply technology for large-scale social housing projects.

- Disaster-Resilient Reconstruction: When stabilized with cement, compressed earth blocks can meet high structural standards. Their availability and low cost make them a viable solution for rebuilding communities after natural disasters, offering a dignified and sustainable alternative to temporary shelters.

- Niche Architectural and Landscape Design: There is a growing demand from architects and landscape designers for adobe bricks for feature walls, garden landscaping, and interior design elements, representing a high-margin, low-volume market segment.

1.5 A Procurement and Distribution Framework

For commercial stakeholders, several factors are critical for successful market entry and operations.

- Conducting Local Material Suitability Analysis: A crucial first step is to test local soils for their suitability. Distributors should partner with or have access to soil testing labs to provide this service to potential clients, de-risking their investment.

- Analyzing the Total Cost of Ownership and ROI: The business case must include not only the machine’s price but also costs for site preparation, power, labor, and raw material processing. The return on investment is often driven by the low cost of materials and the premium value of the final product in certain markets.

- Building a Robust Technical Support and Spare Parts Network: Given that this technology can be deployed in remote areas, having a reliable supply chain for spare parts—especially for hydraulic seals and mold components—is essential. Providing comprehensive operator training programs will minimize downtime and build customer loyalty.

- Navigating Building Codes and Standards: A significant part of market development involves educating local building authorities and engineers about the structural and durability standards that modern, stabilized adobe bricks can meet. Providing technical data and certification from international bodies can facilitate this process.

Conclusión

The adobe brick machine is far more than a piece of manufacturing equipment; it is a gateway to a sustainable, cost-effective, and culturally resonant building paradigm. It effectively bridges the gap between timeless traditional wisdom and modern industrial efficiency. For forward-thinking distributors and procurement specialists, this technology offers a strategic opportunity to diversify their portfolio and lead in the burgeoning eco-construction market. Success hinges not just on selling a machine, but on selling a complete system—including expertise in soil science, production methodology, and market development—that empowers clients to build a more sustainable future, one brick at a time.

Frequently Asked Questions (FAQ)

Q1: How does the durability and water resistance of machine-made adobe compare to traditional sun-dried bricks?

A: Machine-made, compressed adobe bricks are significantly more durable. The high-pressure compaction creates a far denser matrix with lower porosity, leading to higher compressive strength and better resistance to erosion. When chemically stabilized (e.g., with 5-8% cement), their resistance to water penetration is greatly enhanced, making them suitable for use in a wider range of climates.

Q2: What is the typical learning curve for operators to produce consistent, high-quality bricks?

A: The learning curve is generally short. For manual presses, basic proficiency can be achieved in a few days. Mastering the optimal moisture content and fill level for maximum density and consistency may take a few weeks of practice. For hydraulic and automated machines, operator training focuses more on machine operation, maintenance, and troubleshooting, which can be accomplished in a structured one- to two-week training program.

Q3: Can these machines use soil directly from the excavation site, or does it require processing?

A: While the ideal scenario is to use on-site soil, it almost always requires some processing. The soil must first be tested for its clay-sand-silt ratio. It then typically needs to be dried, crushed to break up clods, and screened to remove stones and organic debris. Most production setups include a crusher and a rotary or vibratory screen as essential auxiliary equipment.

Q4: What are the primary maintenance requirements for a hydraulic adobe press?

A: Maintenance is relatively straightforward but crucial. Key tasks include:

- Daily: Cleaning the mold and hopper, checking for hydraulic fluid leaks.

- Weekly: Inspecting hydraulic hoses and connections, checking fluid levels.

- Monthly: Cleaning or replacing hydraulic oil filters, inspecting the electrical system.

- Annually: Replacing the hydraulic oil and conducting a comprehensive inspection of the press cylinder and seals.

Q5: How does the cost of producing a machine-made adobe brick compare to a conventional fired clay brick?

A: The production cost is generally 20-40% lower. The primary savings come from the elimination of the energy-intensive firing process (kiln fuel) and the use of low-cost, locally available raw materials. The main costs in adobe production are labor, stabilizer (if used), and machine depreciation.

Q6: Are there limitations on the architectural designs that can be achieved with adobe bricks?

A: While adobe construction is well-suited for load-bearing wall systems with straightforward geometries, modern engineering allows for significant design flexibility. Incorporating reinforced concrete bond beams and lintels enables the creation of larger openings and complex shapes. However, extremely intricate curvatures or very tall, slender structures are better suited to other building systems.