1. Introduction

The term “lego brick” has become synonymous with modular, interlocking design—offering simplicity, versatility, and structural stability in countless applications. Translating this concept to construction, lego brick making machines produce interlocking bricks that fit together like toy blocks, eliminating the need for mortar and enabling fast, efficient assembly. For distributors, distributors, and purchasers operating in construction, landscaping, infrastructure, and DIY markets, these machines represent a high-growth product category with diverse applications. Unlike traditional brick making equipment, lego brick making machines are engineered to create precise, uniform bricks with interlocking features that enhance structural integrity, reduce construction time, and lower labor costs.

2. Corps

2.1 Core Design and Engineering of Lego Brick Making Machines

Lego brick making machines are precision-engineered to produce bricks with consistent dimensions, tight interlocking tolerances, and durable construction. Their design prioritizes modularity, repeatability, and adaptability to different brick sizes and shapes—key differentiators from traditional brick making equipment. Understanding these design elements is critical for distributors to communicate value and support end-users.

2.1.1 Composantes structurelles clés

The design of lego brick making machines revolves around precision and modularity, with components optimized for interlocking brick production:

- Cadre et Base: Constructed from heavy-duty steel (8-10 mm thick) to provide stability during high-pressure compaction (20-40 MPa). The base features reinforced anchor points and vibration-dampening pads to minimize movement and ensure brick dimensional accuracy. Frames are available in compact (1.5×1.2×1.8 meters) for small-scale operations and industrial (3.0×2.0x2.5 meters) for high-volume production, with weights ranging from 300 kg to 2,000 kg.

- Modular Mold Assembly: The mold is the most critical component, defining the brick’s interlocking geometry and dimensions. Molds are CNC-machined from hardened steel (HRC 55-60) to ensure precision tolerances (±0.5 mm) and long life. Lego-style interlocking features include raised studs (2-5 mm height) and corresponding recesses on opposite brick faces, creating a mechanical bond that eliminates mortar. Molds are modular, allowing quick changes (10-15 minutes) between sizes (e.g., 200x100x60 mm, 250x125x80 mm, 300x300x100 mm) and interlocking patterns (stud-and-recess, tongue-and-groove, puzzle). Most machines come with 2-3 standard molds, with custom molds available for specialized designs.

- Compaction Mechanism: Lego bricks require uniform, high-pressure compaction to ensure structural integrity and tight interlocking fits. Machines use three primary compaction systems:

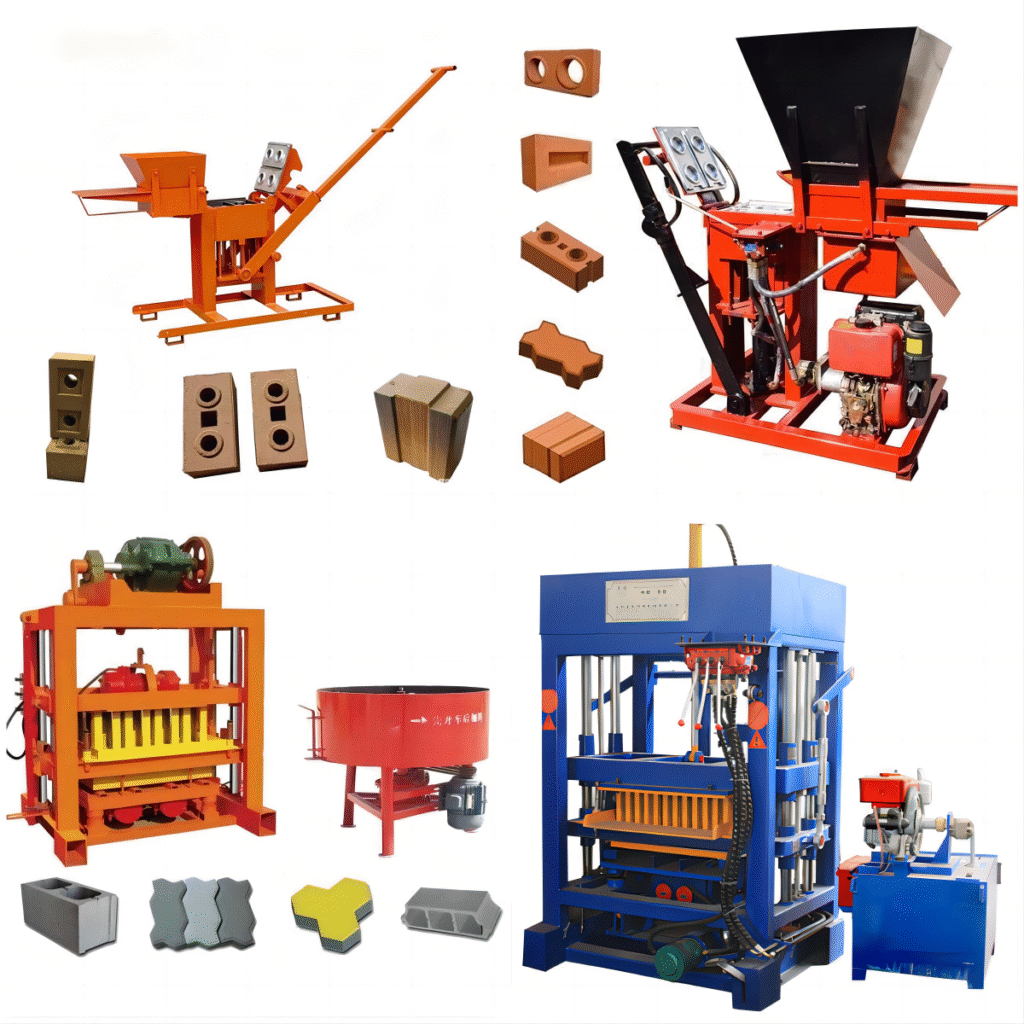

- Hydraulique (Semi-Automatique): Most common for small to medium-scale operations (200-600 bricks/hour). Hydraulic cylinders generate 20-30 MPa pressure, with adjustable pressure settings for different materials (concrete, soil-cement, recycled aggregates).

- Electric-Powered (Automatic): For high-volume production (600-1,500 bricks/hour). Electric motors (10-20 HP) drive compaction plates, with PLC controls for precise pressure and cycle time management.

- Manual (Lever/Screw-Driven): For small-scale, low-budget operations (100-200 bricks/hour). Manual lever or screw systems generate 15-20 MPa pressure, suitable for DIY enthusiasts or rural contractors.

- Feeding and Demolding Systems: The feeding system uses a hopper with a vibratory feeder to ensure uniform material distribution in the mold—critical for brick consistency. Demolding is automated or semi-automated: hydraulic ejector plates lift the brick from the mold without damaging interlocking features, while some manual models use spring-loaded release mechanisms. Advanced machines include a conveyor system for automatic brick stacking, reducing labor costs.

2.1.2 Material Compatibility and Brick Production

Lego brick making machines are versatile, supporting a range of materials to meet different application needs:

- Concrete-Based Mixtures: Most common for construction and landscaping. Mixes include sand, gravel, cement (10-15%), and water (8-12% moisture content). Concrete lego bricks offer high strength (10-20 MPa) and durability, suitable for load-bearing walls, driveways, and commercial projects.

- Soil-Cement Mixtures: For sustainable, low-cost applications. Mixes include local soil (60-80%), sand (10-20%), cement (5-10%), and water (12-18% moisture content). Soil-cement lego bricks have strength of 4-8 MPa, ideal for low-rise housing, rural construction, and affordable housing projects.

- Recycled Aggregate Mixtures: For eco-friendly applications. Mixes include crushed concrete, brick fragments, or industrial byproducts (fly ash, slag) mixed with cement. Recycled lego bricks have strength of 8-12 MPa, suitable for non-load-bearing walls, landscaping, and sustainable construction projects.

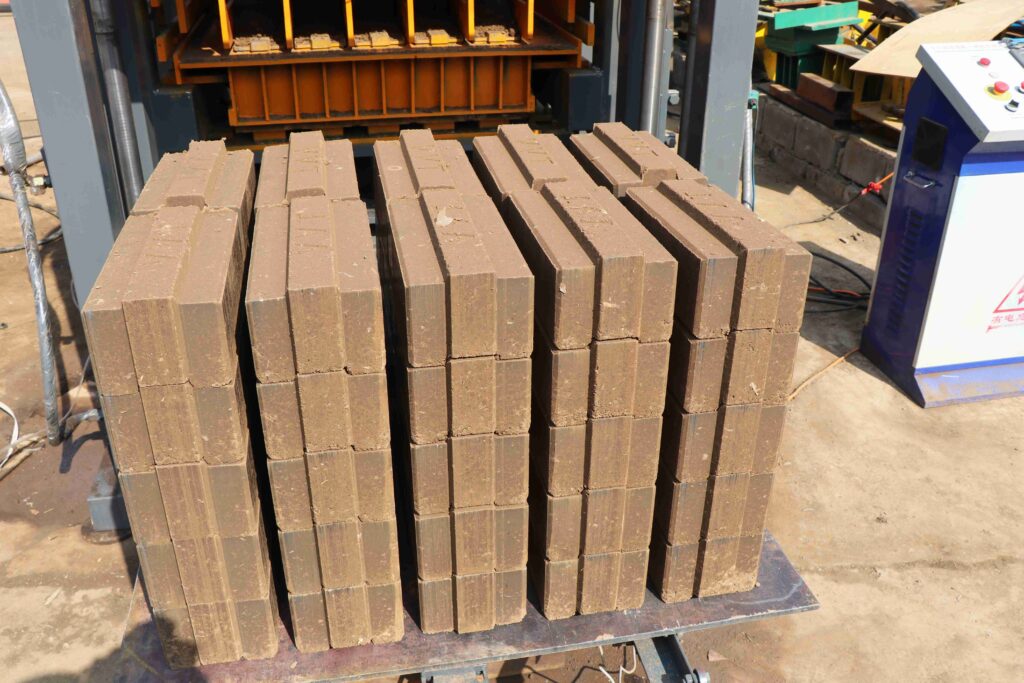

- Production Workflow:

- Material Preparation: Mix aggregates, binder (cement), and water to achieve the ideal consistency. For concrete mixes, use a concrete mixer; for soil-cement mixes, use a paddle mixer.

- Alimentation: Load the mixture into the machine’s hopper, which feeds it into the mold via a vibratory feeder.

- Compaction: The compaction mechanism applies pressure (15-40 MPa) to the mixture, densifying it into the lego brick shape.

- Demolding: The brick is ejected from the mold and transferred to a curing area (manual stacking or automatic conveyor).

- Guérison: Bricks cure for 7-28 days (concrete) or 14-28 days (soil-cement) to achieve full strength. Curing can be natural (air-drying) or accelerated (using curing compounds or humidity chambers).

2.1.3 Technical Specifications to Prioritize

When evaluating lego brick making machines for procurement or distribution, key technical specifications include:

- Capacité de production: 100-1,500 bricks/hour, depending on machine type:

- Manual: 100-200 bph.

- Semi-Automatic Hydraulic: 200-600 bph.

- Automatic Electric: 600-1,500 bph.

- Brick Strength: 4-20 MPa, depending on material and compaction pressure:

- Soil-Cement: 4-8 MPa.

- Recycled Aggregate: 8-12 MPa.

- Concrete: 10-20 MPa.

- Dimensional Accuracy: ±0.5 mm for length, width, and height—critical for interlocking fit. Machines with CNC-machined molds ensure consistent accuracy.

- Mold Life: 20,000-50,000 cycles for standard steel molds, depending on material abrasiveness. Replaceable mold inserts extend life by 50-70%.

- Exigences en matière d'alimentation électrique:

- Manual: No electricity.

- Semi-Automatic Hydraulic: 5-10 HP electric motor or diesel engine (for remote areas).

- Automatic Electric: 10-20 HP electric motor (3-phase, 220/380V).

2.2 Market Value Propositions: Why Lego Brick Making Machines Drive Demand

Lego brick making machines offer a unique set of value propositions that resonate with contractors, builders, landscapers, and DIY enthusiasts. Distributors who emphasize these benefits can capture market share in construction, landscaping, and sustainable building sectors.

2.2.1 Faster Construction and Labor Cost Savings

The modular, interlocking design of lego bricks reduces construction time by 30-50% compared to traditional mortar-based bricks:

- No Mortar Required: Interlocking bricks fit together tightly without mortar, eliminating the time-consuming process of mixing, applying, and curing mortar. A team of 2-3 workers can build a 10 m² wall in 1-2 days with lego bricks, compared to 3-4 days with traditional bricks.

- Simplified Assembly: The interlocking design requires minimal skill—workers can learn to assemble lego brick walls in a few hours, reducing the need for skilled masons (who command higher wages). This lowers labor costs by 20-30% for construction projects.

- Reduced Curing Time: Lego bricks cure faster than traditional mortar joints. Concrete lego bricks cure in 7-14 days (vs. 21-28 days for mortar joints), allowing projects to progress faster.

- Example: A small residential house (100 m²) built with lego bricks requires 8,000-10,000 bricks and takes 2-3 weeks to construct, compared to 4-6 weeks with traditional bricks. Labor costs are reduced by $1,000-$2,000 USD.

2.2.2 Structural Integrity and Versatility

Lego bricks offer superior structural stability and design flexibility, making them suitable for diverse applications:

- Mechanical Bond Strength: The interlocking design creates a stronger bond than mortar, with lego brick walls resisting lateral forces (wind, seismic activity) 20-30% better than traditional walls. This is critical for disaster-prone regions or high-wind areas.

- Design Flexibility: Modular lego bricks can be assembled into curved walls, arches, columns, and custom shapes without cutting or modifying bricks. This versatility appeals to architects, landscapers, and DIY enthusiasts seeking creative designs.

- Multi-Application Use: Lego bricks are suitable for:

- Construction: Load-bearing walls, non-load-bearing walls, foundations, and retaining walls.

- Landscaping: Driveways, patios, walkways, garden edging, and retaining walls.

- DIY Projects: Garden sheds, playhouses, raised garden beds, and decorative features.

- Scalability: Lego bricks are available in multiple sizes, from small pavers (100x100x50 mm) to large wall bricks (300x300x100 mm), allowing scalability for projects of any size.

2.2.3 Cost Savings and Affordability

Lego brick making machines offer long-term cost savings for both producers and end-users:

- Reduced Material Costs: Lego bricks use 5-10% less material than traditional bricks due to their hollow or ribbed design (optional for some models), reducing raw material costs by 5-10%.

- Lower Transportation Costs: Interlocking bricks can be stacked more efficiently (20-30% higher density) than traditional bricks, reducing transportation costs by 15-20% per load.

- Low Maintenance: Lego brick walls require minimal maintenance—no repointing of mortar joints, reducing long-term maintenance costs by 40-50%.

- ROI for Producers: For brick makers, lego brick making machines offer an ROI of 6-18 months, depending on production volume. A semi-automatic machine producing 400 bricks/hour (3,200 bricks/day) generates $160-$320 USD per day in revenue (at $0.05-$0.10 per brick profit).

2.2.4 Sustainability and Eco-Friendliness

Lego brick making machines align with global sustainability goals, making them attractive to eco-conscious contractors, government agencies, and green building projects:

- Reduced Carbon Footprint: Concrete lego bricks use 10-15% less cement than traditional concrete bricks (due to optimized mix design), reducing carbon emissions by 10-15% per brick. Soil-cement and recycled aggregate lego bricks further reduce emissions by 50-70%.

- Waste Reduction: The precision production process generates less than 2% material waste, compared to 10-15% for traditional brick making. Excess material can be reused in future batches.

- Recycled Material Compatibility: Lego brick making machines can process recycled aggregates (crushed concrete, brick fragments) and industrial byproducts (fly ash, slag), diverting waste from landfills and reducing reliance on virgin materials.

- Energy Efficiency: Modern lego brick making machines use energy-efficient motors and hydraulic systems, reducing energy consumption by 15-25% compared to traditional brick making equipment.

2.3 Target Markets and Customer Segments for Distributors

Lego brick making machines appeal to diverse customer segments, each with unique needs and purchasing drivers. Distributors who tailor their offerings to these segments can maximize sales and customer satisfaction.

2.3.1 Small Contractors and Builders

This is the largest customer segment, consisting of small-scale contractors handling residential, commercial, and landscaping projects:

- Budget: $1,500-$8,000 USD. Prioritize semi-automatic hydraulic machines with 200-600 bph capacity.

- Needs: Versatility (multiple brick sizes), ease of operation, and durability. Target applications: small houses, garages, driveways, and garden walls.

- Market Regions: Urban and peri-urban areas in emerging economies (Kenya, India, Nigeria, Brazil) and developed countries (US, Europe, Australia).

- Selling Strategy: Emphasize labor cost savings, faster construction, and design flexibility. Offer training on brick production and wall assembly. Provide a starter kit with 2-3 standard molds and a mixing tool.

2.3.2 Brick Manufacturers and Large Construction Firms

Brick manufacturers and large construction companies form a high-volume segment:

- Budget: $8,000-$30,000 USD. Purchase automatic electric machines with 600-1,500 bph capacity.

- Needs: High production capacity, PLC controls for quality control, and custom mold capabilities. Target applications: large housing estates, commercial buildings, and infrastructure projects.

- Market Regions: Major cities and industrial zones worldwide.

- Selling Strategy: Highlight production efficiency, consistent brick quality, and scalability. Offer custom mold design services for branded or specialized bricks. Provide technical support for machine installation, maintenance, and process optimization.

2.3.3 Landscaping Companies and DIY Enthusiasts

Landscaping firms and DIY enthusiasts form a growing niche segment:

- Budget: $500-$5,000 USD. Prioritize small semi-automatic or manual machines for paver production.

- Needs: Small brick sizes (100x100x50 mm to 300x300x100 mm), decorative interlocking patterns, and ease of use. Target applications: driveways, patios, garden edging, and decorative features.

- Market Regions: Suburban areas in developed countries (US, Europe, Australia) and high-income urban areas in emerging economies.

- Selling Strategy: Emphasize design flexibility, aesthetic appeal, and DIY-friendly operation. Offer decorative mold sets (textured, colored, custom shapes) and marketing materials showcasing landscaping projects. Partner with home improvement stores and landscaping supply retailers.

2.3.4 Government Agencies and Affordable Housing Projects

Government bodies and NGOs implementing affordable housing, infrastructure, and sustainable development projects are valuable institutional customers:

- Budget: $5,000-$20,000 USD per machine. Purchase in bulk (5+ machines) for large-scale projects.

- Needs: Durability, low-cost production (soil-cement or recycled materials), and compliance with green building standards.

- Market Regions: Emerging economies with active affordable housing initiatives (India, Kenya, Brazil, Indonesia) and disaster-prone areas (Nepal, Haiti, Philippines).

- Selling Strategy: Highlight cost savings for public budgets, sustainability credentials, and social impact (job creation). Provide technical documentation (brick strength tests, carbon footprint reports) and training programs for local workers. Partner with international organizations (UN Habitat, World Bank) to secure project-based orders.

2.4 Procurement and Distribution Strategies for Profitability

For distributors and purchasers, successful procurement and distribution of lego brick making machines require strategic planning to ensure quality, minimize costs, and reach target customers effectively.

2.4.1 Sourcing Reliable Suppliers

Selecting the right supplier is critical to securing high-quality machines optimized for lego brick production:

- Manufacturer Criteria: Prioritize suppliers with 5+ years of experience in interlocking brick machine production, with a focus on lego-style designs. Look for ISO 9001 certification (quality management) and compliance with safety standards (CE, ASTM, OSHA). Request sample bricks produced by the machine to test dimensional accuracy, interlocking fit, and strength.

- Quality Control Checks: Inspect sample machines for:

- Mold precision (CNC-machined, tolerance ±0.5 mm).

- Compaction pressure consistency (variation <5%).

- Frame rigidity (no bending or vibration during operation).

- Ease of mold change (≤15 minutes for standard molds).

- Supplier Support: Ensure suppliers offer:

- Detailed operation and maintenance manuals (with video tutorials for visual learners).

- Spare parts (molds, compaction plates, hydraulic seals) at competitive prices with short lead times (2-4 weeks).

- Technical support via phone, email, or video call (24/7 for critical issues).

- Training for distributors and end-users (on-site or online).

- Minimum Order Quantities (MOQs): Most manufacturers require MOQs of 3-5 machines for wholesale pricing. For small distributors, partner with other regional distributors to meet MOQs and secure 10-20% volume discounts.

2.4.2 Pricing and Margin Optimization

Setting competitive prices while maintaining profitability requires understanding cost structures and market willingness to pay:

- Cost Structure Breakdown: Calculate total cost per machine, including:

- Supplier price (FOB/CIF): $1,000-$25,000 USD (manual to automatic).

- Shipping and import duties: 10-40% of CIF value (varies by country).

- Local transportation and storage: $100-$500 USD per machine.

- Training and after-sales support: $100-$300 USD per machine.

- Pricing Strategy:

- Manual models: Retail price $500-$1,500 USD (30-40% markup).

- Semi-Automatic Hydraulic models: $1,500-$8,000 USD (35-50% markup).

- Automatic Electric models: $8,000-$30,000 USD (40-60% markup).

- Bulk orders (5+ machines): Offer 10-15% discounts to institutional customers.

- Value-Added Services to Boost Margins:

- Custom mold design: $300-$1,500 USD per set (depending on complexity).

- Branding services: Laser engraving of company logos on bricks (for manufacturers).

- Training workshops: $200-$500 USD per session (for contractors or brick makers).

- Maintenance contracts: $200-$1,000 USD per year (including spare parts and technical support).

2.4.3 Distribution Channel Optimization

Reaching target customers requires channels that align with their location, budget, and purchasing behavior:

- Direct Sales: Sell directly to large construction firms, brick manufacturers, and government agencies via online platforms (Alibaba, LinkedIn), trade shows (Bauma, CONEXPO, GLEE), and direct sales teams. Direct sales maximize margins (35-60%) and allow for customized solutions.

- Retail Partnerships: Collaborate with construction supply stores, home improvement retailers (e.g., Lowe’s, B&Q equivalents), and landscaping supply companies to stock small to medium-scale machines. Offer retailers a 15-25% commission, along with point-of-purchase displays and marketing materials.

- Online Sales: Sell small manual and semi-automatic machines via e-commerce platforms (Amazon, eBay, local online marketplaces) to DIY enthusiasts and small contractors. Invest in product videos, detailed descriptions, and customer reviews to build trust.

- Rental Services: For high-cost automatic machines, offer rental options (daily/weekly/monthly rates) to small brick makers or contractors with short-term projects. Rentals generate recurring revenue and allow customers to test the machine before purchasing.

2.4.4 After-Sales Support and Customer Retention

Effective after-sales support is critical to building customer loyalty and generating repeat business:

- Training: Provide hands-on training for machine operators, covering material preparation, machine operation, mold change, and basic maintenance. For large customers, offer specialized training for quality control and process optimization.

- Spare Parts Availability: Stock common spare parts locally to reduce delivery time. For remote areas, partner with local mechanics or construction supply stores to stock and sell spare parts.

- Technical Support: Offer a dedicated customer support line, email, and WhatsApp number for troubleshooting. For complex issues, dispatch a technician (for large customers) or provide video call support with step-by-step instructions.

- Customer Feedback and Loyalty Programs: Regularly follow up with customers (1 month, 6 months, 1 year post-purchase) to gather feedback, address issues, and share new mold designs or machine upgrades. Implement a loyalty program (discounts on future purchases, free spare parts) to encourage repeat business.

2.5 Market Trends and Future Opportunities for Lego Brick Making Machines

The market for lego brick making machines is growing rapidly, driven by global trends in construction efficiency, sustainability, and design flexibility. Distributors who stay ahead of these trends can capitalize on emerging opportunities.

2.5.1 Growing Demand for Modular and Prefabricated Construction

Modular and prefabricated construction is becoming increasingly popular due to its speed, efficiency, and cost savings. Lego bricks align perfectly with this trend:

- Modular Assembly: Lego bricks can be prefabricated into wall panels, columns, and other components in a factory, then transported to the construction site for quick assembly. This reduces on-site construction time by 50-70%.

- Prefabrication Benefits: Prefabricated lego brick components offer consistent quality, reduced waste, and lower labor costs. They are ideal for large-scale housing projects, hotels, and commercial buildings.

- Opportunity: Market lego brick making machines as a key tool for modular construction. Partner with prefabrication companies and large construction firms to supply machines for component production.

2.5.2 Technological Advancements for Lego Brick Making Machines

Manufacturers are incorporating advanced technologies to enhance machine performance and functionality:

- IoT and Remote Monitoring: Modern automatic machines include IoT sensors that monitor production volume, compaction pressure, and machine health. Operators can track performance remotely via a smartphone app, enabling predictive maintenance and process optimization.

- 3D-Printed Molds: 3D printing technology allows for fast, cost-effective production of custom molds for complex interlocking patterns or decorative designs. This reduces mold lead times from weeks to days and lowers costs for small-batch custom orders.

- Eco-Friendly Materials: Manufacturers are developing machines optimized for bio-based binders (e.g., lime, natural resins) and recycled materials, further reducing the environmental impact of lego brick production.

- Opportunity: Offer these advanced machines at a 20-30% premium, targeting tech-savvy customers and sustainable construction firms. Highlight the benefits of IoT monitoring (reduced downtime, improved efficiency) and 3D-printed molds (design flexibility, fast customization).

2.5.3 Expansion into Niche Markets: Decorative and Smart Bricks

Lego brick making machines are expanding into niche markets with specialized brick designs:

- Decorative Bricks: Custom molds for textured, colored, or patterned lego bricks are in demand for high-end landscaping, interior design, and eco-tourism projects. Decorative lego bricks can be painted, stained, or finished with natural materials (e.g., stone chips) for unique aesthetics.

- Smart Bricks: Lego bricks integrated with sensors (temperature, humidity, structural stress) are emerging for smart buildings. These bricks can monitor building performance and alert owners to maintenance issues or safety hazards.

- Opportunity: Develop specialized mold sets for decorative bricks and partner with architects, interior designers, and smart building companies to promote smart brick applications.

2.5.4 Government Initiatives and Green Building Standards

Governments worldwide are implementing policies and incentives to promote sustainable construction, creating opportunities for lego brick making machines:

- Green Building Certifications: Lego bricks made from recycled materials or soil-cement qualify for green building certifications (LEED, BREEAM, GRIHA), which offer tax incentives and priority in government projects.

- Affordable Housing Subsidies: Governments in emerging economies are subsidizing sustainable construction equipment for affordable housing projects. Lego brick making machines are ideal for these projects due to their low cost and efficiency.

- Infrastructure Development: Governments are investing in infrastructure projects (roads, bridges, retaining walls) that use interlocking bricks for durability and speed. For example, the Indian government’s Pradhan Mantri Gram Sadak Yojana (PMGSY) uses interlocking bricks for rural road construction.

- Opportunity: Position lego brick making machines as compliant with green building standards and eligible for government subsidies. Partner with local distributors to bid on government tenders and secure large-scale orders.

3. Conclusion

Lego brick making machines represent a game-changing innovation in the global construction and landscaping industries—combining speed, efficiency, versatility, and sustainability to address critical market needs. For distributors, distributors, and purchasers, these machines offer a high-growth, profitable product category that aligns with trends in modular construction, sustainable building, and design flexibility. By understanding the precision engineering and modular design of lego brick making machines, distributors can effectively communicate their value propositions—faster construction, labor cost savings, structural integrity, and environmental benefits—to target customer segments ranging from small contractors to large construction firms and government agencies.

The unique advantages of lego-style interlocking bricks make them suitable for diverse applications, from residential and commercial construction to landscaping and DIY projects. As the world shifts toward more efficient, sustainable, and cost-effective construction methods, the demand for lego brick making machines will continue to grow, creating significant opportunities for industry professionals who adapt to market trends and prioritize customer needs.

For purchasers, lego brick making machines offer a reliable, cost-effective solution for brick production, with quick ROI and minimal environmental impact. For distributors, they represent a chance to build profitable businesses while contributing to positive industry change—reducing construction waste, lowering carbon emissions, and improving access to affordable housing. In a world where efficiency and sustainability are increasingly important, lego brick making machines are more than just construction equipment—they are tools for building faster, stronger, and more sustainable communities.

4. FAQ

4.1 What is the production capacity of a lego brick making machine?

Lego brick making machines have production capacities ranging from 100-1,500 bricks per hour (bph), depending on the machine type:

- Manual (lever/screw-driven): 100-200 bph.

- Semi-Automatic Hydraulic: 200-600 bph.

- Automatic Electric: 600-1,500 bph.For small-scale operations (contractors, DIY enthusiasts), semi-automatic models (200-600 bph) are most popular, while brick manufacturers and large construction firms prefer automatic models (600-1,500 bph) for high-volume production.

4.2 What materials can be used in a lego brick making machine?

Lego brick making machines support three primary material types:

- Concrete-Based: Sand, gravel, cement (10-15%), and water (8-12% moisture). Produces high-strength bricks (10-20 MPa) for construction and landscaping.

- Soil-Cement: Local soil (60-80%), sand (10-20%), cement (5-10%), and water (12-18% moisture). Produces low-cost, sustainable bricks (4-8 MPa) for affordable housing and rural construction.

- Recycled Aggregate: Crushed concrete, brick fragments, or industrial byproducts (fly ash, slag) mixed with cement. Produces eco-friendly bricks (8-12 MPa) for non-load-bearing walls and landscaping.

4.3 How much does a lego brick making machine cost, and what is the ROI?

Lego brick making machines range in price from $500-$30,000 USD:

- Manual models: $500-$1,500 USD.

- Semi-Automatic Hydraulic models: $1,500-$8,000 USD.

- Automatic Electric models: $8,000-$30,000 USD.ROI varies by machine type and production volume:

- Manual: 12-18 months (low-volume, DIY or rural use).

- Semi-Automatic: 6-12 months (medium-volume, contractors or small brick makers).

- Automatic: 6-9 months (high-volume, brick manufacturers or large construction firms).ROI is driven by brick selling price ($0.10-$0.30 per brick) and production cost ($0.02-$0.10 per brick).

4.4 What is the compressive strength of lego bricks, and are they suitable for load-bearing walls?

Lego bricks have compressive strengths ranging from 4-20 MPa:

- Soil-Cement: 4-8 MPa (suitable for non-load-bearing walls, low-rise load-bearing walls <2 stories).

- Recycled Aggregate: 8-12 MPa (suitable for non-load-bearing walls, retaining walls, and low-rise load-bearing walls).

- Concrete: 10-20 MPa (suitable for load-bearing walls, commercial buildings, and infrastructure projects).Concrete lego bricks with 10+ MPa strength meet local building codes for load-bearing walls in most countries, making them suitable for residential and commercial construction.

4.5 How long do lego bricks last, and what maintenance is required for the walls?

Lego bricks are highly durable with a lifespan of 50-100 years, comparable to traditional bricks:

- Weather Resistance: Concrete and recycled aggregate lego bricks are resistant to rain, wind, and temperature fluctuations. Soil-cement bricks may require a lime wash or waterproof coating in humid climates.

- Maintenance: Lego brick walls require minimal maintenance—no repointing of mortar joints. Occasional cleaning (to remove dirt or algae) is sufficient. For decorative bricks, re-painting or staining every 5-10 years may be needed for aesthetic purposes.

4.6 Can lego brick making machines produce custom brick sizes or shapes?

Yes, most lego brick making machines use modular molds that can be customized to produce different sizes, shapes, and interlocking patterns:

- Standard Sizes: 200x100x60 mm, 250x125x80 mm, 300x300x100 mm (wall bricks); 100x100x50 mm, 200x200x80 mm (pavers).

- Custom Sizes: Molds can be designed for any size (minimum 50x50x25 mm, maximum 500x500x200 mm) to meet project-specific needs.

- Custom Shapes: Decorative shapes (curved, triangular, textured) and interlocking patterns (puzzle, tongue-and-groove, custom logos) are available via custom mold design. Custom molds cost $300-$1,500 USD per set, with lead times of 2-4 weeks.

4.7 Are lego brick making machines easy to operate, and what training is required?

Lego brick making machines are designed for ease of operation, with minimal training required:

- Manual/Semi-Automatic Models: Operators can learn basic operation in 1-2 hours (material preparation, feeding, compaction, demolding).

- Automatic Models: Operators require 1-2 days of training to learn PLC controls, mold changes, and maintenance.Most suppliers offer free basic training with machine purchase, including hands-on demonstrations and written manuals. For large customers, specialized training for quality control and process optimization is available for an additional fee.

4.8 What power source is required for lego brick making machines?

Power requirements vary by machine type:

- Manual Models: No electricity—operated via lever or screw.

- Semi-Automatic Hydraulic Models: 5-10 HP electric motor (220/380V, single/three-phase) or diesel engine (for remote areas with no grid access).

- Automatic Electric Models: 10-20 HP electric motor (3-phase, 380V) with PLC controls.For areas with unreliable power, semi-automatic models with diesel engines or dual-power (electric + diesel) options are available, ensuring uninterrupted production.