1. Introduzione

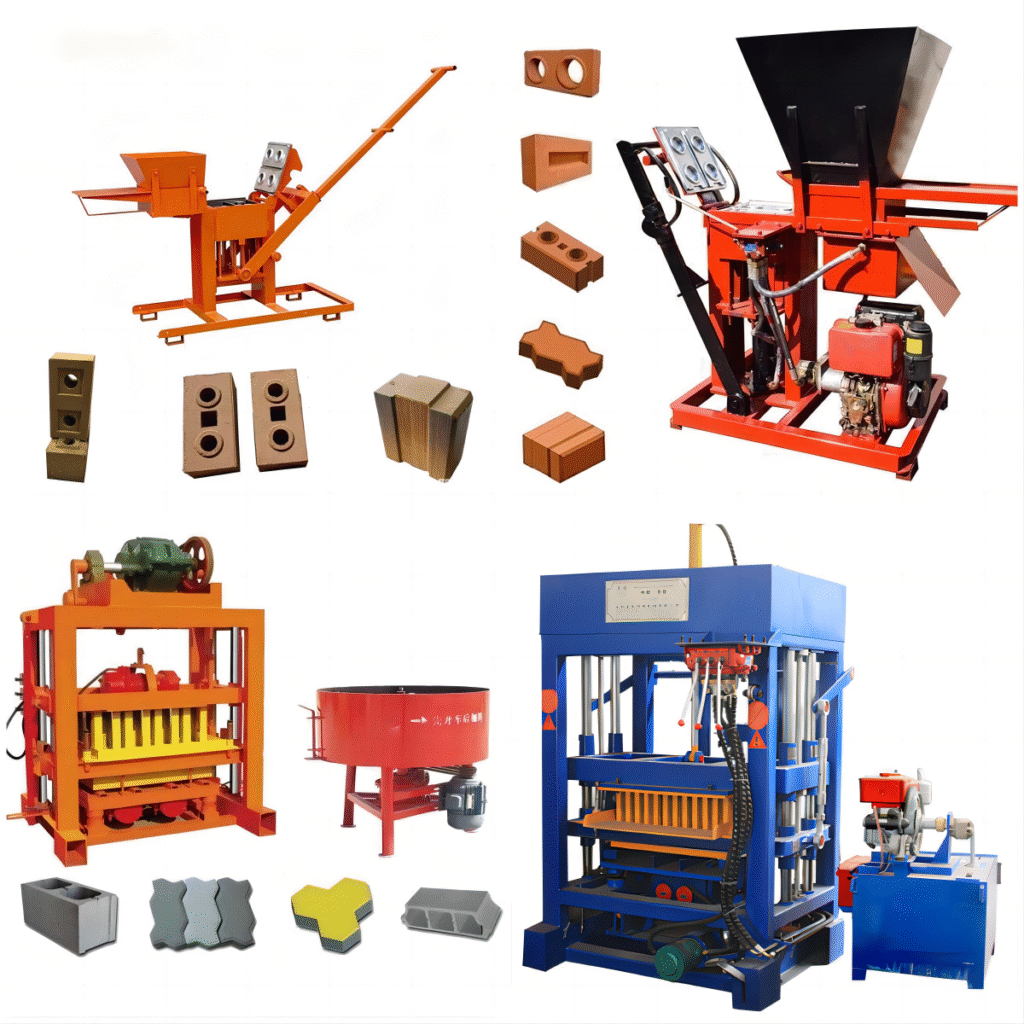

In the global construction equipment market, interlocking manual brick machines occupy a critical niche—catering to cost-sensitive, low-volume, and remote operations where automation or power access is limited. For distributors, distributors, and purchasers, these machines represent a high-potential product category, especially in emerging economies, rural regions, and small-scale construction sectors. Unlike automated or semi-automated counterparts, interlocking manual brick machines rely on human effort for feeding, compaction, and demolding, offering unmatched affordability, portability, and simplicity.

2. Corpo

2.1 Progettazione di Base e Meccanica Operativa delle Macchine Manuali per Mattoni a Incastro

Le macchine manuali per mattoni a incastro sono progettate per semplicità, durata e facilità d'uso, con elementi costruttivi che privilegiano l'operatività intuitiva rispetto all'automazione complessa. Comprenderne i componenti strutturali e i principi di funzionamento è fondamentale affinché i distributori possano trasmettere il valore ai clienti e supportare efficacemente gli utenti finali.

2.1.1 Componenti Strutturali Chiave

Il design delle macchine manuali per mattoni ad incastro è ridotto ai componenti essenziali, garantendo affidabilità e bassa manutenzione. Le parti critiche includono:

- Telaio e BaseCostruito in acciaio di spessore elevato (tipicamente 4-6 mm) per garantire stabilità durante la compattazione. La base è dotata di piedini in gomma antiscivolamento o punti di ancoraggio per impedire movimenti durante il funzionamento. Telai compatti (tipicamente 1,0×0,8×1,2 metri) e il design leggero (50-150 kg) consentono un facile trasporto tramite pick-up, motocicli o persino a mano in aree remote.

- Assemblaggio dello StampoLo stampo è il componente più critico, in quanto definisce la forma, le dimensioni e le caratteristiche d'incastro del mattone. Gli stampi sono realizzati in acciaio temprato o ghisa (HRC 45-55) per resistere alle ripetute forze di compattazione. I disegni d'incastro variano—le opzioni comuni includono maschio-femmina, zigzag e modelli simili a puzzle—ognuno progettato per migliorare la stabilità strutturale senza malta. La maggior parte delle macchine manuali include 1-2 stampi standard (ad es. 200x100x60 mm, 250x125x80 mm), con stampi modulari disponibili per cambi rapidi (5-10 minuti) a un costo aggiuntivo.

- Meccanismo di CompattazioneLe macchine manuali utilizzano leve meccaniche o sistemi a vite per generare pressione di compattazione (5-20 MPa). I modelli a leva presentano un lungo manico (1,5-2,0 metri) che amplifica la forza umana, mentre i modelli a vite impiegano una manovella rotante per applicare pressione verso il basso. La piastra di compattazione è realizzata in acciaio temprato e allineata per garantire una distribuzione uniforme della pressione, fondamentale per la densità e la resistenza del mattone.

- Sistemi di Alimentazione e SmodellamentoLa tramoggia di alimentazione ha un design semplice e aperto superiormente (capacità 5-10 kg) che consente agli operatori di versare direttamente i materiali grezzi miscelati nello stampo. Lo smolto è manuale o semimanuale: alcuni modelli dispongono di una piastra espellitore a molla che solleva il mattone dopo la compattazione, mentre altri richiedono agli operatori di picchiettare delicatamente lo stampo o utilizzare uno strumento di distacco. La semplicità di questi sistemi riduce al minimo i guasti e diminuisce la necessità di competenze tecniche.

2.1.2 Flusso Operativo di Lavoro

Operating an interlocking manual brick machine involves four straightforward steps, making it accessible to operators with minimal training:

- Preparazione delle Materie Prime: Operators mix aggregates (sand, gravel, crushed stone) with binding agents (cement, lime, or soil) and water to achieve the ideal moisture content (8-12%). Manual machines can process a wide range of raw materials, including local soils (laterite, clay), recycled construction waste, and industrial byproducts (fly ash), reducing material costs for end-users.

- Feeding the Mold: The mixed material is poured into the mold cavity, and excess material is scraped off with a flat tool to ensure uniform filling. Some machines feature a vibrator attachment (manual or battery-powered) to settle the material and eliminate air pockets, improving brick density.

- Compattazione: The operator uses the lever or crank to apply compaction pressure. Lever-operated models require 20-30 kg of force, while screw-driven models need 15-25 kg—effort that most adults can sustain for extended periods (8-10 hours/day). Compaction time per brick is 10-30 seconds, depending on the machine and operator skill.

- Smontaggio e Polimerizzazione: After compaction, the operator releases the brick from the mold and places it on a curing surface. Manual machines produce “green bricks” that require curing (7-28 days) to achieve structural strength (3-10 MPa, suitable for non-load-bearing walls, driveways, and low-rise buildings).

2.1.3 Technical Specifications to Prioritize

When evaluating interlocking manual brick machines for procurement or distribution, key technical specifications include:

- Production Capacity: 100-500 bricks per hour (bph), depending on operator skill and machine design. Lever-operated models typically produce 100-250 bph, while screw-driven models offer 200-500 bph. For distributors, this capacity aligns with small-scale operations (1,000-4,000 bricks per day), making the machines ideal for micro-entrepreneurs.

- Brick Strength: Compressive strength ranges from 3-10 MPa, sufficient for residential walls, landscaping, and low-load applications. Higher-quality machines (with better compaction mechanisms) can achieve 8-10 MPa, competing with semi-automatic models for small commercial projects.

- Durability: Frame lifespan should be 5-10 years with proper maintenance, while molds should last 10,000-30,000 cycles (depending on material). Replaceable mold parts (e.g., interlocking teeth) are a valuable feature, extending the machine’s usable life.

- Weight and Portability: Machines weighing 50-100 kg are most marketable, as they can be transported without specialized equipment. Foldable handles or detachable components further enhance portability for remote areas.

2.2 Market Value Propositions: Why Interlocking Manual Brick Machines Drive Demand

Interlocking manual brick machines offer a unique set of value propositions that resonate with purchasers in target segments—especially in price-sensitive, low-resource environments. Distributors who emphasize these benefits can differentiate their offerings and capture market share.

2.2.1 Unmatched Affordability

The primary driver of demand for manual interlocking brick machines is their low upfront cost, making them accessible to micro-entrepreneurs and small contractors with limited capital:

- Purchase Price: Manual machines range from $200-$1,500 USD, compared to $1,600-$5,200 for small-scale semi-automatic models. This 70-80% cost reduction is a game-changer for purchasers in emerging economies, where access to financing is limited.

- Low Operational Costs: Zero energy consumption (no electricity or diesel) eliminates monthly utility bills, a major advantage in regions with high energy costs or unreliable power. Labor costs are minimal—one operator can run a manual machine, compared to 2-3 operators for semi-automatic models.

- Quick ROI: With a production cost of $0.05-$0.10 per brick and a selling price of $0.15-$0.30 per brick, manual machines offer an ROI of 3-9 months, even for low-volume operations (1,000 bricks/day). This rapid payback period is a key selling point for risk-averse purchasers.

2.2.2 Portability and Accessibility

Manual machines are designed for operations in remote or hard-to-reach areas, addressing a critical gap in the market:

- No Power Dependency: Unlike electric or diesel-powered machines, manual models require no external power, making them ideal for rural areas, informal settlements, or disaster-stricken regions where grid access is unavailable.

- Easy Transportation: Lightweight (50-150 kg) and compact design allows transportation via motorcycles, bicycles, or animal-drawn carts—common modes of transport in rural Africa, Asia, and Latin America. For example, in rural Kenya or India, a manual machine can be transported to a construction site in a pickup truck or even carried by two people.

- On-Site Production: Manual machines enable on-site brick production, eliminating transportation costs for finished bricks (which can account for 30-40% of total costs). This is particularly valuable for small projects (e.g., a single-family home) or remote sites where brick delivery is impractical.

2.2.3 Simplicity and Low Maintenance

Manual interlocking brick machines require minimal technical expertise to operate and maintain, reducing barriers to adoption:

- Easy Operation: The straightforward workflow (feeding, compaction, demolding) can be learned in 1-2 hours, with no need for formal training. Operators with basic literacy can follow simple instructions, making the machines accessible to unskilled labor.

- Minimal Maintenance: With no motors, hydraulics, or complex electronics, manual machines have few moving parts to maintain. Routine maintenance includes lubricating hinges and screws (monthly), cleaning the mold (daily), and replacing worn mold parts (annually). Maintenance costs are typically less than $50 USD per year.

- Durability in Harsh Conditions: Manual machines are designed to withstand dusty, humid, or rugged environments, with no sensitive components prone to damage. This durability is critical for purchasers in regions with limited access to repair services.

2.2.4 Sustainability and Local Material Utilization

Manual interlocking brick machines align with global sustainability goals and local resource availability:

- Eco-Friendly Production: No energy consumption means zero carbon emissions during operation. Additionally, manual machines can process local soils, recycled construction waste, and agricultural byproducts (e.g., rice husk ash), reducing reliance on imported materials and minimizing environmental impact.

- Reduced Waste: The compaction process produces minimal material waste (less than 5%), compared to 10-15% for traditional manual brick making. This efficiency saves costs and reduces environmental footprint.

- Compliance with Green Standards: In regions with growing focus on sustainable construction (e.g., LEED, BREEAM, or local green building codes), manual machines’ ability to use recycled materials and produce low-carbon bricks makes them attractive to NGOs, government projects, and eco-conscious contractors.

2.3 Target Markets and Customer Segments for Distributors

Interlocking manual brick machines appeal to distinct customer segments, each with unique needs and purchasing drivers. Distributors who tailor their offerings to these segments can maximize sales and customer satisfaction.

2.3.1 Micro-Entrepreneurs and Small Brick Makers

This is the largest customer segment, consisting of individuals or small teams (2-3 people) starting brick-making businesses. Key characteristics:

- Budget: $200-$800 USD, with no access to financing. Prioritize low upfront cost over advanced features.

- Needs: Portability, ease of operation, and compatibility with local raw materials. Target production: 500-2,000 bricks/day.

- Market Regions: Rural areas, informal settlements, and small towns in emerging economies (e.g., Nigeria, India, Bangladesh, Kenya, Tanzania).

- Selling Strategy: Emphasize quick ROI, low maintenance, and on-site production. Offer basic training (1-2 hours) and affordable spare parts (molds, lubricants). Package machines with starter kits (mold, mixing tool, measuring container) to increase value.

2.3.2 Small Contractors and Builders

Contractors handling small-scale projects (single-family homes, small commercial buildings, rural schools/clinics) form the second-largest segment:

- Budget: $500-$1,500 USD. Willing to pay more for higher capacity and durability.

- Needs: Production capacity (200-500 bph), modular molds for different brick types, and reliability for project deadlines.

- Market Regions: Peri-urban areas and small cities in emerging economies, as well as remote regions in developed countries (e.g., rural Australia, Canada, or the US).

- Selling Strategy: Highlight brick quality (strength, consistency), time savings compared to traditional brick making, and cost reduction from on-site production. Offer extended warranties (1-2 years) and on-site support for project kickoffs.

2.3.3 NGOs and Government Agencies

NGOs and government bodies supporting affordable housing, disaster relief, or rural development projects are valuable institutional customers:

- Budget: $800-$1,500 USD per machine. Purchase in bulk (10+ machines) for community projects.

- Needs: Durability, compatibility with local materials, and ability to train community members quickly. Prioritize sustainability and social impact.

- Market Regions: Disaster-prone areas (e.g., Haiti, Philippines, Nepal), rural development zones, and low-income housing projects.

- Selling Strategy: Emphasize social impact (job creation, affordable housing), sustainability (recycled material use, low carbon footprint), and scalability (bulk pricing, training programs for communities). Partner with local NGOs to demonstrate project success and secure repeat orders.

2.3.4 Educational Institutions and Vocational Training Centers

Technical schools and vocational training centers purchase manual machines to teach brick-making skills to students:

- Budget: $500-$1,200 USD. Prioritize safety, ease of training, and durability for frequent use.

- Needs: Simple design, safety features (e.g., rounded edges, non-slip handles), and modular components for teaching different brick types.

- Market Regions: All countries, with a focus on regions with high youth unemployment (e.g., South Africa, Brazil, Indonesia).

- Selling Strategy: Highlight educational value, safety features, and compatibility with training curricula. Offer customized training materials (manuals, videos) and discounted bulk pricing for institutions.

2.4 Procurement and Distribution Strategies for Maximum Profitability

For distributors and purchasers, successful procurement and distribution of interlocking manual brick machines require strategic planning to minimize costs, ensure quality, and reach target customers effectively.

2.4.1 Sourcing Reliable Suppliers

Selecting the right supplier is critical to securing high-quality machines and avoiding costly issues:

- Manufacturer Criteria: Prioritize suppliers with 3+ years of experience producing manual interlocking brick machines. Look for manufacturers with ISO 9001 certification (quality management) and compliance with safety standards (e.g., CE, ASTM). Request factory photos, production videos, and sample machines for testing.

- Quality Control: Inspect sample machines for frame thickness, mold material, compaction pressure, and ease of operation. Test the machine by producing 100+ bricks to check for consistency in size, density, and strength. Verify that spare parts (molds, compaction plates) are readily available and affordable.

- Minimum Order Quantities (MOQs): Most manufacturers require MOQs of 5-10 machines for wholesale pricing. For small distributors, partner with other local distributors to meet MOQs and secure volume discounts (10-15% off).

- Lead Times and Shipping: Lead times should be 2-6 weeks for standard machines. Choose sea freight for bulk orders (cost-effective) or air freight for urgent orders (faster but 3-5x more expensive). Factor in shipping costs, import duties, and clearing fees when calculating total costs.

2.4.2 Pricing and Margin Optimization

Setting the right price is key to balancing competitiveness and profitability:

- Cost Structure: Calculate total cost per machine, including:

- Supplier price (FOB or CIF)

- Shipping, import duties, and taxes (varies by country: 10-40% of CIF value)

- Local transportation and storage

- Training and after-sales support

- Pricing Strategy: Mark up machines by 30-50% for retail sales. For bulk orders (5+ machines), offer 10-15% discounts to attract institutional customers (NGOs, government agencies). In price-sensitive markets, offer basic models at lower margins (20-30%) to drive volume, while premium models (with modular molds, vibrator attachments) can carry higher margins (40-60%).

- Value-Added Services: Increase profitability by offering complementary products and services:

- Starter kits (mixing tools, measuring containers, curing covers): $20-$50 USD

- Additional molds: $50-$150 USD per set

- Training sessions: $50-$100 USD per machine

- Maintenance contracts: $30-$60 USD per year

2.4.3 Distribution Channel Optimization

Reaching target customers requires selecting the right distribution channels for your market:

- Direct Sales: Sell directly to customers via online platforms (e.g., Alibaba, local e-commerce sites), social media (Facebook, WhatsApp), or trade shows. Direct sales maximize margins but require marketing and customer support resources.

- Partner Distribution: Collaborate with local hardware stores, construction supply retailers, and agricultural cooperatives to stock your machines. Offer retailers a 15-25% commission on sales, along with training and marketing materials.

- Institutional Partnerships: Partner with NGOs, government agencies, and international development organizations (e.g., UN Habitat, World Bank) to supply machines for community projects. These partnerships can drive bulk sales and enhance brand credibility.

- Mobile Demonstrations: Conduct on-site demonstrations in rural areas and construction sites to showcase the machine’s ease of use and brick quality. Demonstrations are highly effective in regions where customers prefer to test products before purchasing.

2.4.4 After-Sales Support and Customer Retention

Providing effective after-sales support is critical to building customer loyalty and generating repeat business:

- Training: Offer free basic training (1-2 hours) for each machine sold. For institutional customers, provide group training sessions for community members or workers.

- Spare Parts Availability: Stock common spare parts (molds, compaction plates, lubricants) locally to reduce delivery time. Offer spare parts at 10-20% markup to generate additional revenue.

- Technical Support: Provide a dedicated phone number or WhatsApp line for troubleshooting. For complex issues, partner with local mechanics to offer on-site repairs at a reasonable cost.

- Customer Feedback: Regularly follow up with customers (1 month, 3 months, 6 months after purchase) to gather feedback, address issues, and promote additional products (e.g., new molds, maintenance kits). Satisfied customers are likely to refer others, driving organic sales.

2.5 Market Trends and Future Opportunities for Interlocking Manual Brick Machines

The market for interlocking manual brick machines is evolving, driven by global trends in sustainability, rural development, and affordable housing. Distributors and purchasers who stay ahead of these trends can capitalize on emerging opportunities.

2.5.1 Growing Demand for Affordable Housing

Governments and NGOs worldwide are investing in affordable housing projects to address urbanization and housing shortages. For example:

- The Kenyan government’s Affordable Housing Program aims to build 500,000 low-cost units annually, creating demand for low-cost brick-making equipment.

- India’s Pradhan Mantri Awas Yojana (PMAY) targets 20 million affordable homes by 2024, with a focus on sustainable and locally sourced materials.

- International organizations like UN Habitat are funding housing projects in disaster-stricken regions, where manual machines are ideal for quick, on-site production.

- Opportunity: Position manual machines as a key tool for affordable housing projects, highlighting cost savings, local material use, and job creation. Partner with government agencies and NGOs to secure bulk orders.

2.5.2 Sustainability and Circular Economy

The global push for sustainable construction is driving demand for eco-friendly building materials and equipment:

- Manual machines’ ability to process recycled construction waste (e.g., crushed concrete, brick fragments) aligns with circular economy goals, reducing landfill waste and raw material costs.

- In regions with strict environmental regulations (e.g., EU, US), manual machines are gaining traction for small-scale eco-friendly projects (e.g., green roofs, permaculture gardens).

- Opportunity: Market manual machines as “sustainable brick-making solutions,” emphasizing zero carbon emissions, recycled material compatibility, and low environmental impact. Obtain green certifications (e.g., ECOLOGO, Green Seal) to enhance credibility.

2.5.3 Technological Improvements for Manual Machines

While manual machines prioritize simplicity, manufacturers are incorporating minor technological improvements to enhance performance without increasing complexity:

- Battery-Powered Vibrator Attachments: Small, rechargeable vibrators (12V) improve material compaction, increasing brick strength by 20-30% without adding significant cost ($50-$100 USD).

- Ergonomic Design: Improved lever handles (padded, adjustable length) and lightweight materials (aluminum alloys for non-load-bearing components) reduce operator fatigue, increasing production capacity by 10-15%.

- Modular Mold Systems: Quick-change molds (5 minutes) allow operators to produce multiple brick types (pavers, wall bricks, decorative bricks) with one machine, expanding market versatility.

- Opportunity: Offer these enhanced models at a 15-20% premium, targeting customers who want improved performance without sacrificing manual operation’s core benefits.

2.5.4 Expansion into Niche Markets

Manual interlocking brick machines are finding new applications in niche markets, creating additional revenue streams:

- Landscaping and Gardening: Small, decorative interlocking bricks produced by manual machines are in demand for garden paths, patios, and flower bed edging. Target homeowners, landscaping companies, and resorts.

- Disaster Relief: Manual machines are ideal for post-disaster reconstruction, as they require no power and can be quickly deployed to produce bricks for temporary shelters and permanent housing. Partner with humanitarian organizations to supply machines for disaster zones.

- Vocational Training: Technical schools and NGOs are using manual machines to teach brick-making skills to unemployed youth, creating a market for training-specific machines (safe, easy to use, durable).

- Opportunity: Develop specialized models for these niche markets (e.g., small molds for landscaping bricks, safety-focused models for training) to differentiate your product portfolio.

3. Conclusion

Interlocking manual brick machines represent a high-value, low-risk product category for distributors, distributors, and purchasers operating in cost-sensitive, low-resource, and remote markets. Their unique combination of affordability, portability, simplicity, and sustainability addresses unmet needs for micro-entrepreneurs, small contractors, NGOs, and government agencies—creating sustainable business opportunities across the globe. By understanding the core design and operational mechanics of these machines, distributors can effectively communicate their value propositions, target the right customer segments, and implement procurement and distribution strategies that maximize profitability.

The future of interlocking manual brick machines is bright, driven by growing demand for affordable housing, sustainability goals, and technological improvements that enhance performance without compromising simplicity. Distributors who adapt to market trends—such as offering enhanced models with vibrator attachments or modular molds, partnering with institutional customers, and expanding into niche markets—will position themselves for long-term success. For purchasers, manual machines offer a cost-effective, reliable solution for small-scale brick production, with quick ROI and minimal operational risks.

In a world where accessibility and sustainability are increasingly important, interlocking manual brick machines are more than just construction equipment—they are tools for economic empowerment, community development, and environmental stewardship. By investing in these machines, distributors and purchasers are not only building profitable businesses but also contributing to a more inclusive and sustainable construction industry.

4. FAQ

4.1 What is the production capacity of an interlocking manual brick machine?

Interlocking manual brick machines typically produce 100-500 bricks per hour (bph), depending on the machine design and operator skill. Lever-operated models average 100-250 bph, while screw-driven models offer 200-500 bph. With a skilled operator working 8 hours/day, production ranges from 800-4,000 bricks per day—ideal for small-scale operations and micro-entrepreneurs.

4.2 What raw materials can be used in an interlocking manual brick machine?

Manual machines are highly versatile and can process a wide range of raw materials, including:

- Aggregates: Sand, gravel, crushed stone, laterite, clay, and volcanic ash.

- Binding agents: Cement, lime, soil, or organic binders (e.g., cow dung for low-strength bricks).

- Recycled materials: Crushed concrete, brick fragments, construction waste, and agricultural byproducts (rice husk ash, maize stalk ash).

- The ideal mix depends on local availability and desired brick strength—most operators use a 3:1 aggregate-to-binder ratio with 8-12% moisture content.

4.3 How much does an interlocking manual brick machine cost, and what is the ROI?

Manual interlocking brick machines range in price from $200-$1,500 USD. Basic lever-operated models cost $200-$600, while premium screw-driven models with modular molds cost $600-$1,500. The ROI is typically 3-9 months, based on:

- Production cost: $0.05-$0.10 per brick (raw materials + labor).

- Selling price: $0.15-$0.30 per brick (varies by region and brick type).

- Production volume: 500-2,000 bricks/day (low-volume operations).

4.4 What is the compressive strength of bricks produced by manual machines?

Bricks produced by interlocking manual brick machines have a compressive strength of 3-10 MPa. Basic models (5-10 MPa compaction pressure) produce bricks with 3-6 MPa strength, suitable for non-load-bearing walls, driveways, and landscaping. Premium models (10-20 MPa compaction pressure) or those with vibrator attachments can achieve 8-10 MPa strength, sufficient for low-rise load-bearing walls and small commercial projects.

4.5 How portable are interlocking manual brick machines, and how are they transported?

Manual machines are highly portable, with a compact design (1.0×0.8×1.2 meters) and weight of 50-150 kg. They can be transported via:

- Pickup trucks, vans, or small lorries for medium-distance transport.

- Motorcycles, bicycles, or animal-drawn carts for short distances in rural areas.

- Hand-carrying by 2-3 people for remote sites with no vehicle access.Most models feature foldable handles or detachable components to further enhance portability.

4.6 What maintenance is required for an interlocking manual brick machine?

Maintenance requirements are minimal, with routine tasks including:

- Daily: Clean the mold to remove dried material and inspect for damage.

- Weekly: Lubricate hinges, screws, and moving parts with grease or oil.

- Monthly: Check the frame for cracks or deformation and tighten loose bolts.

- Annually: Replace worn mold parts (e.g., interlocking teeth) or compaction plates.Total annual maintenance costs are typically less than $50 USD, with no need for specialized tools or technical expertise.

4.7 Can manual machines produce different types of interlocking bricks?

Yes, most manual machines support modular mold systems that allow quick changes (5-10 minutes) between different brick sizes, shapes, and interlocking patterns. Common options include:

- Standard wall bricks: 200x100x60 mm, 250x125x80 mm.

- Landscaping pavers: 250x250x80 mm, 300x300x100 mm.

- Decorative bricks: Textured surfaces, curved edges, or custom patterns.Additional molds cost $50-$150 USD per set, allowing operators to expand their product offerings without purchasing a new machine.

4.8 Are there any safety features in interlocking manual brick machines?

While manual machines are simple, reputable manufacturers include basic safety features to protect operators:

- Rounded edges on the frame and lever to prevent cuts and bruises.

- Non-slip handles and base to reduce accidents during compaction.

- Reinforced mold locks to prevent material spillage or mold movement.

- Clear operating instructions (with illustrations) for unskilled operators.For training or institutional use, some models offer additional safety features (e.g., guard rails, pressure limiters) to minimize risk during group operation.