1. Company Heritage and Manufacturing Philosophy

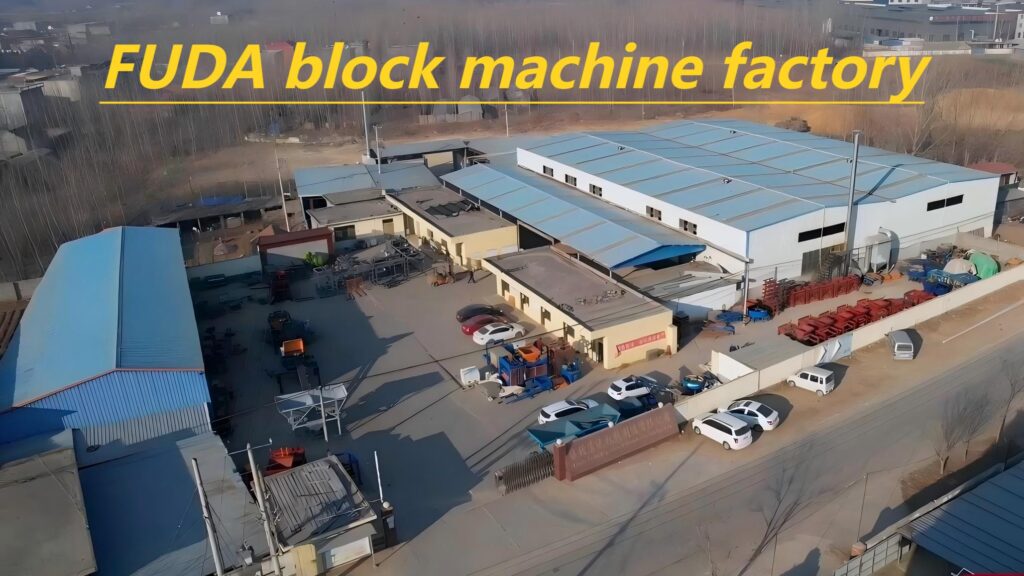

Fuda block brick machinery factory is built upon a deep-seated commitment to industrial craftsmanship and innovation. With years of specialized experience in the design and production of block-making equipment, the company has evolved from a focused workshop into a full-scale manufacturing hub. Its philosophy centers on creating robust, efficient, and user-friendly machines that meet the practical demands of brick production facilities worldwide.

The manufacturing process is governed by stringent quality control protocols, from the sourcing of high-grade raw materials like hardened steel and precision components to final assembly and testing. Every machine is subjected to rigorous performance evaluations to ensure it operates at specified standards before leaving the factory floor. This dedication to quality ensures that partners receive equipment that minimizes downtime and maximizes return on investment.

2. Core Product Line: Clay Brick and Block Making Machines

The factory’s product range is meticulously engineered to cater to various production scales and output requirements.

2.1. Automatic Clay Brick Making Machines

These flagship systems represent the pinnacle of automation in brick manufacturing. Designed for high-volume production, they integrate clay feeding, high-pressure molding, automatic brick setting, and stacking into one seamless process. Key features often include:

- High-Pressure Hydraulic Systems: Ensures consistent brick density and strength, producing bricks with excellent structural integrity and low moisture absorption rates.

- Controladores Lógicos Programáveis (CLPs): Allow for easy operation, precise control over production cycles, and quick changeovers for different brick sizes or styles.

- Robotic Handling and Palletizing: Automates the transfer and stacking of green bricks, significantly reducing labor costs and handling damage.

2.2. Semi-Automatic and Manual Block Machines

Understanding the diverse market needs, the factory also offers robust semi-automatic and manually operated machines. These are ideal for medium to small-scale operations, start-up businesses, or regions with specific cost structures. They provide an excellent balance between productivity, affordability, and operational flexibility, allowing operators to produce high-quality blocks with lower initial capital expenditure.

2.3. Complementary Production Line Equipment

A complete production line requires more than just a brick press. The factory supplies a fully integrated ecosystem of machinery, including:

- Clay Crushers and Mixers: Prepare the raw material to a consistent, optimal consistency for molding.

- Brick Cutting and Splitting Devices: Create specialty shapes and finishes.

- Automatic Stackers and Unstackers: Facilitate the handling and drying of bricks.

- Tunnel Kiln Cars and Transfer Systems: For factories incorporating in-house firing processes.

3. Technological Innovation and Engineering Excellence

Staying competitive requires continuous innovation. The factory’s engineering team focuses on several key technological areas:

- Eficiência Energética: Modern machines are designed to consume less power per brick produced, incorporating energy-saving motors and optimized hydraulic circuits. This directly lowers the operating costs for end-users.

- Durability and Low Maintenance: The use of wear-resistant materials in critical components like molds, heads, and rollers extends the machine’s service life. Easy-access designs simplify routine maintenance.

- Versatilidade na Produção de Produtos: Through interchangeable molds and adjustable systems, a single machine can often produce a wide array of products—from solid bricks and hollow blocks to pavers and interlocking landscaping stones—enabling partners to serve multiple market segments.

- Smart Manufacturing Integration: Newer models offer connectivity features for production monitoring, facilitating data collection on output, downtime, and efficiency, which aids in preventative maintenance and production planning.

4. Support Systems for Business Partners

For distributors and procurement agents, the partnership extends beyond the sale of equipment. The factory provides a comprehensive support structure designed to ensure business success.

- Technical Training: Extensive training programs are offered for both the partner’s technical staff and the end-client’s operators. This covers installation, daily operation, troubleshooting, and maintenance procedures.

- After-Sales Service and Spare Parts Network: A reliable global supply chain for genuine spare parts is maintained to ensure quick turnaround. Technical support is available via remote diagnostics and, when necessary, dispatches of field service engineers.

- Market and Business Development Support: The factory often assists partners with marketing collateral, technical data sheets, and participation in joint ventures or trade shows to help grow their local market presence.

- Customization and OEM Services: Recognizing specific regional standards or client needs, the factory offers engineering services to customize machines or develop completely OEM-branded solutions for large distributors.

5. The Value Proposition for Distributors and Procurement Specialists

Aligning with this manufacturer presents several strategic advantages for business intermediaries:

- Product Reliability: Distributing proven, durable machinery builds credibility and reduces costly warranty claims and service headaches.

- Competitive Pricing Structure: Efficient manufacturing processes and vertical integration allow for competitive pricing, giving partners healthy margins and market flexibility.

- Scalable Product Range: The ability to supply everything from a single machine to a complete turnkey plant allows partners to cater to a broad customer base, from small entrepreneurs to large industrial clients.

- Strong Brand Reputation: Associating with a manufacturer known for quality and innovation enhances the distributor’s own brand equity in the marketplace.

Conclusão

Selecting the right manufacturing partner for construction machinery is a pivotal decision that influences long-term business viability. This clay brick machine factory distinguishes itself through a steadfast commitment to quality, a comprehensive and innovative product portfolio, and an unwavering focus on partner success. Its blend of robust engineering, practical automation, and holistic support services creates a compelling proposition for dealers, distributors, and procurement professionals worldwide. By providing the tools to produce high-quality building materials efficiently and reliably, this manufacturer does more than sell machines—it empowers its partners to build sustainable, profitable businesses and contribute to the infrastructure development of their regions. For those in the supply chain seeking a dependable source of advanced clay brick machinery, this factory stands as a premier choice worthy of serious consideration.

FAQ

Q1: What is the typical production output range of the automatic brick making machines offered?

A: Output varies significantly by model and block type. Standard automatic lines can range from producing 10,000 to 30,000 standard brick equivalents per 8-hour shift. Specific output for a particular model and product specification can be provided upon request with your production requirements.

Q2: How does the factory ensure the quality and durability of its machines?

A: Quality is ensured through a multi-stage process: using certified materials (like graded steel), precision CNC machining for critical parts, advanced welding techniques, and assembly by experienced technicians. Every machine undergoes a comprehensive running test under load before shipment to verify performance and stability.

Q3: What kind of training and support is provided after the purchase?

A: We provide detailed installation manuals and wiring diagrams. Typically, we offer on-site installation guidance and operator/maintenance training by our engineers for key projects. Remote support is available via video call, and we maintain a complete catalog of readily available spare parts to minimize downtime.

Q4: Can the machines be customized for specific brick sizes or local raw materials?

A: Yes, a key strength is customization. We can design and manufacture molds for virtually any standard or special brick size and shape. Furthermore, our engineering team can advise on machine settings and, if necessary, minor modifications to optimally process local clay characteristics.

Q5: What are the payment terms and delivery lead times?

A: Standard payment terms often include a deposit with order and balance before shipment. Lead times depend on the machine model and current order backlog; for standard models, it typically ranges from 30 to 60 days after receipt of deposit. Exact terms and schedules are confirmed with every formal quotation.

Q6: Is the factory capable of supplying a complete turnkey production plant?

A: Absolutely. We specialize in providing complete solutions, from raw material handling equipment (crushers, mixers) and brick-making machines to brick setting systems and transfer cars. We can design the entire layout and supply the full line as a integrated project.