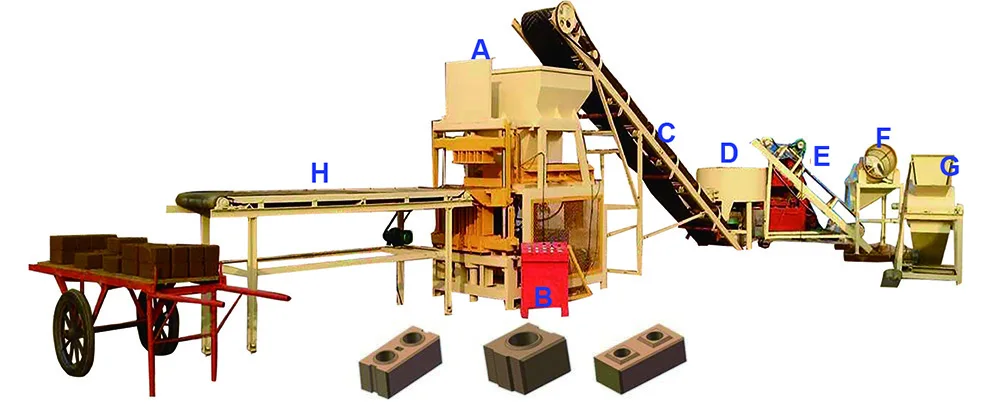

Suas características são forte pressão hidráulica e operação totalmente automática. O operador só precisa configurar o programa no painel de controle, e a máquina pode completar automaticamente todo o ciclo de: posicionamento da caixa do molde → alimentação quantitativa automática → pré-carga por vibração → prensagem hidráulica de alta pressão → desmoldagem automática e ejeção dos blocos de tijolo → redefinição da caixa do molde. Reduz significativamente a dependência da mão de obra, geralmente exigindo apenas 1-2 pessoas para monitorar o equipamento e transportar os tijolos.

|

Potência total da máquina hospedeira

|

11KW

|

|

Ciclo de moldagem

|

10s

|

|

Tamanho da máquina de tijolos

|

1500*400*1000mm

|

|

Peso

|

3000 KGS

|

|

Tamanho do palete

|

Não precisa

|

|

Item

|

Bloco

|

Capacidade de produção

|

Foto

|

|

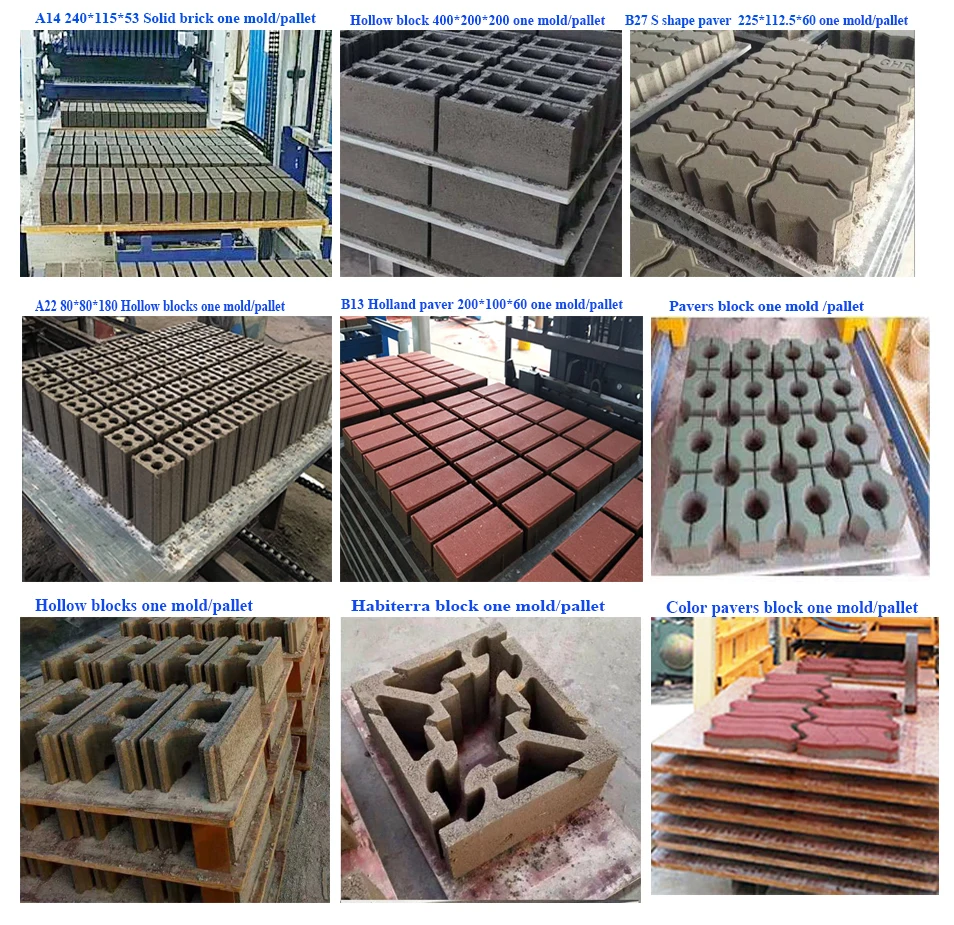

1

|

Bloco Faull

|

4 peças/molde

11520/8h |

1, 2, 4, 5, 7, 8, 9, 10, 11, 12

|

|

2

|

Meio bloco

|

8 peças/molde

23040/8h |

Não 3,6

|