1. บทนำ

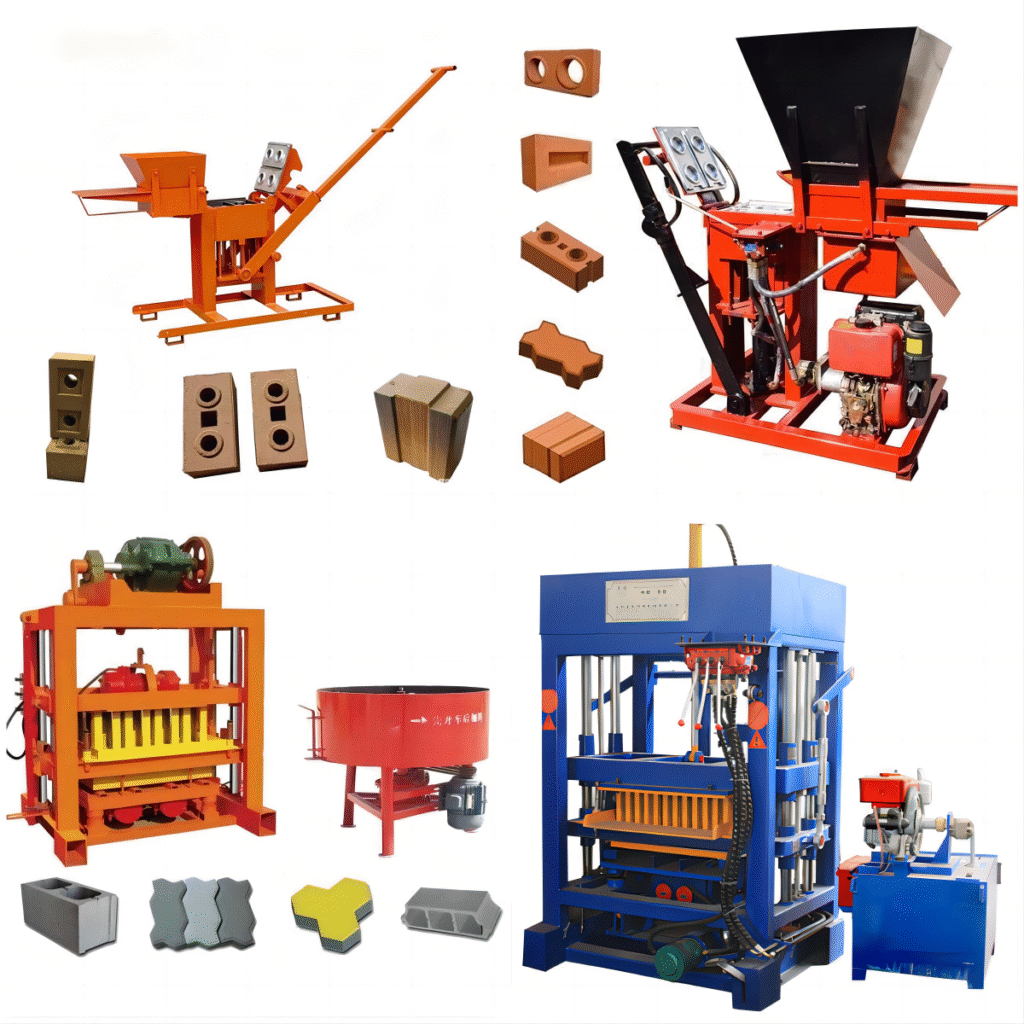

In the global shift toward sustainable and affordable construction, interlocking soil brick machines have emerged as a transformative solution—leveraging one of the most abundant, low-cost raw materials on Earth: soil. For distributors, distributors, and purchasers operating in construction, infrastructure, and community development sectors, these machines represent a high-potential product category that aligns with environmental goals, cost-saving objectives, and social impact initiatives. Unlike traditional brick-making equipment that relies on cement, aggregates, or fired clay, interlocking soil brick machines are engineered to compact locally sourced soil (often mixed with minimal binders) into durable, interlocking bricks—eliminating the need for mortar and reducing carbon footprints.

2. ร่างกาย

2.1 การออกแบบและวิศวกรรมหลักเพื่อความเข้ากันได้กับดิน

เครื่องอัดดินก้อนประสานได้รับการออกแบบมาโดยเฉพาะเพื่อจัดการกับคุณสมบัติทางกายภาพของดิน ซึ่งประกอบด้วยความไวต่อความชื้น ความหลากหลายของขนาดอนุภาค และลักษณะการยึดเกาะ ต่างจากเครื่องจักรที่ออกแบบสำหรับคอนกรีตหรือดินเหนียว การออกแบบของเครื่องเหล่านี้ให้ความสำคัญกับประสิทธิภาพการอัดดิน ความแข็งแรงของโครงสร้างประสาน และความสามารถในการปรับใช้กับดินประเภทต่างๆ การทำความเข้าใจองค์ประกอบการออกแบบเหล่านี้มีความสำคัญอย่างยิ่งสำหรับผู้จัดจำหน่ายในการสื่อสารคุณค่าและสนับสนุนผู้ใช้งานปลายทาง

2.1.2 ส่วนประกอบโครงสร้างหลักที่ออกแบบเฉพาะสำหรับดิน

การออกแบบเครื่องอัดดินก่อสร้างมุ่งเน้นการปรับปรุงการบดอัดดินและประสิทธิภาพของอิฐให้ดีที่สุด

- กรอบและฐานสร้างจากเหล็กเกจหนา (หนา 6-8 มม.) เพื่อให้มีความมั่นคงระหว่างการอัดดินความดันสูง (10-30 MPa) ฐานมีเท้ากว้างกันลื่นหรือจุดยึดเพื่อป้องกันการเคลื่อนที่ เนื่องจากการอัดดินสร้างแรงด้านข้างมากกว่าคอนกรีตหรือดินเหนียว โครงสร้างมีขนาดกะทัดรัด (1.2×1.0×1.5 เมตร) และน้ำหนักเบา (100-250 กก.) เพื่อความสะดวกในการเคลื่อนย้าย ทำให้สามารถขนส่งไปยังสถานที่ห่างไกลที่มีดินอุดมสมบูรณ์ได้

- Soil-Specific Mold Assembly: Molds are engineered with interlocking geometries (tongue-and-groove, dovetail, or puzzle patterns) that enhance structural stability without mortar. Mold cavities are textured to improve soil adhesion during compaction, reducing brick cracking. Molds are made from hardened steel (HRC 50-55) or reinforced cast iron to withstand abrasive soil particles, with replaceable wear inserts for high-wear areas (e.g., interlocking teeth). Most machines come with 1-2 standard molds (200x100x60 mm, 250x125x80 mm), with custom molds available for specialized brick sizes.

- Compaction Mechanism Optimized for Soil: Soil requires uniform, high-pressure compaction to achieve density and strength. Interlocking soil brick machines use three primary compaction systems:

- Lever-Operated: Manual lever systems (1.8-2.2 meters long) amplify human force to generate 10-15 MPa pressure, suitable for clay-rich or loamy soils. Ideal for small-scale operations (100-250 bricks/hour).

- Screw-Driven: Manual or semi-automatic screw systems apply 15-25 MPa pressure, compacting sandy or gravelly soils more effectively. Production capacity: 200-400 bricks/hour.

- Hydraulic (Semi-Automatic): Small hydraulic systems (5-10 HP) generate 25-30 MPa pressure, suitable for high-volume operations or clay-poor soils. Production capacity: 300-600 bricks/hour.

- Soil Feeding and Moisture Control: The feeding hopper is designed with a wide opening (30-40 cm diameter) to accommodate loose soil, with a vibrator attachment (manual or electric) to settle soil and eliminate air pockets. Some advanced models include a moisture sensor and adjustable water sprayer to maintain optimal soil moisture (12-18%)—critical for compaction efficiency and brick strength.

2.1.3 Soil Type Compatibility and Preparation

Interlocking soil brick machines are versatile but require soil preparation to ensure brick quality. Key soil considerations include:

- Soil Texture: Machines perform best with loamy soil (40-60% sand, 20-40% silt, 10-20% clay) or clay-loam soil (20-30% clay). Sandy soils require additional clay or a binder (e.g., lime, cement) to improve cohesion, while heavy clay soils need sand to reduce shrinkage and cracking.

- Soil Preparation Steps:

- Sieving: Soil is sieved through a 5-10 mm mesh to remove rocks, roots, and debris that can damage the mold or reduce brick strength.

- Amendment (if needed): For sandy soils, add 5-10% clay or 2-5% lime/cement as a binder. For heavy clay soils, add 10-15% sand to improve workability.

- Moisture Adjustment: Soil moisture is adjusted to 12-18%—enough to allow compaction but not so much that the brick sticks to the mold. Operators can test moisture by squeezing soil: it should hold its shape without dripping.

- Binder Options: While pure soil bricks are possible with high-clay soil, most end-users add 2-5% lime, cement, or organic binders (e.g., cow dung, rice husk ash) to improve strength and durability. This reduces material costs compared to concrete bricks (which require 10-15% cement).

2.1.4 Technical Specifications for Soil Brick Production

When evaluating interlocking soil brick machines, key technical specifications include:

- Production Capacity: 100-600 bricks/hour, depending on compaction type and operator skill. Manual lever models: 100-250 bph; screw-driven: 200-400 bph; hydraulic semi-automatic: 300-600 bph.

- Brick Strength: Compressive strength ranges from 2-8 MPa, suitable for non-load-bearing walls, low-rise load-bearing walls (1-2 stories), driveways, and landscaping. With 5% cement binder, strength can reach 6-8 MPa—compatible with local building codes in most emerging economies.

- Brick Density: Optimal density is 1.8-2.0 g/cm³, achieved through uniform compaction. Density directly impacts brick strength and durability, with under-compacted bricks (density <1.6 g/cm³) prone to cracking.

- Mold Life: 15,000-30,000 cycles for standard steel molds, depending on soil abrasiveness. Replaceable wear inserts extend mold life by 50-70%, reducing maintenance costs.

2.2 Market Value Propositions: Why Interlocking Soil Brick Machines Drive Demand

Interlocking soil brick machines offer a unique set of value propositions that resonate with cost-sensitive, sustainability-focused, and community-driven purchasers. Distributors who emphasize these benefits can capture market share in emerging economies, rural regions, and eco-conscious markets.

2.2.1 Unmatched Cost Savings from Local Soil Utilization

The primary driver of demand for interlocking soil brick machines is their ability to reduce raw material costs by 70-90% compared to concrete or fired clay bricks:

- Raw Material Cost: Soil is free or nearly free (transportation costs only if sourced off-site), while concrete bricks require sand, gravel, and cement (costing $0.10-$0.20 per brick in emerging economies). Soil bricks with 2-5% binder cost $0.02-$0.05 per brick—an 80% reduction.

- Transportation Savings: On-site soil sourcing eliminates transportation costs for raw materials, which can account for 30-40% of total brick costs. For remote projects, this saving is critical, as concrete brick delivery is often impractical or expensive.

- Low Energy Consumption: Manual and semi-automatic soil brick machines use 50-80% less energy than concrete brick machines. Manual models require no electricity, while hydraulic models use 5-10 HP motors—reducing operational costs by $50-$100 per month.

- Quick ROI: With a production cost of $0.02-$0.05 per brick and a selling price of $0.10-$0.25 per brick, interlocking soil brick machines offer an ROI of 4-12 months, even for low-volume operations (1,000 bricks/day).

2.2.2 Environmental Sustainability and Carbon Footprint Reduction

Interlocking soil brick machines align with global climate goals, making them attractive to NGOs, government agencies, and eco-conscious contractors:

- Zero Carbon Emissions: Unlike fired clay bricks (which require burning wood or coal, emitting 1-2 kg CO₂ per brick), soil bricks are compacted without heat—generating zero carbon emissions during production. This reduces the carbon footprint of construction by 60-80%.

- Sustainable Resource Use: Soil is a renewable resource, and responsible sourcing (e.g., from construction site excavations, abandoned quarries) minimizes environmental impact. Using local soil also reduces deforestation (a common side effect of fired brick production, which requires wood for fuel).

- Waste Reduction: Soil brick production generates less than 3% material waste, compared to 10-15% for concrete bricks. Excess soil from mold cleaning can be reused, further minimizing waste.

- Water Efficiency: Soil bricks require 50-70% less water than concrete bricks for production and curing. This is critical in arid regions where water scarcity is a major challenge.

2.2.3 Durability and Performance in Local Conditions

Soil bricks produced by interlocking machines offer surprising durability and performance, addressing common misconceptions about “weak” soil construction:

- Weather Resistance: With proper compaction and a small binder addition (2-5% lime/cement), soil bricks are resistant to rain, wind, and temperature fluctuations. In tropical climates, they provide natural insulation, reducing indoor temperatures by 3-5°C and lowering energy costs for cooling.

- Structural Stability: Interlocking designs create a mechanical bond between bricks, eliminating the need for mortar and improving wall stability. Interlocking soil brick walls have been tested to withstand seismic activity (up to 6.5 magnitude) in regions like Nepal and Haiti, making them ideal for disaster-prone areas.

- Longevity: Well-constructed soil brick buildings have a lifespan of 50-100 years, comparable to concrete structures. Historical examples (e.g., adobe buildings in the American Southwest, cob houses in Europe) demonstrate soil’s durability when properly compacted and maintained.

2.2.4 Social Impact and Community Empowerment

Interlocking soil brick machines drive social impact, making them valuable for NGOs, government development programs, and community projects:

- Job Creation: Small-scale soil brick production creates employment for local workers (operators, soil preparers, brick curers), with one machine supporting 2-5 jobs. This is critical in rural areas with high unemployment.

- Affordable Housing: Soil bricks reduce construction costs by 30-50%, making housing accessible to low-income families. For example, a 50 m² house built with soil bricks costs $3,000-$5,000, compared to $6,000-$10,000 with concrete bricks.

- Skill Development: Operating interlocking soil brick machines requires minimal training (1-2 days), enabling community members to learn a valuable trade and start their own brick-making businesses. This empowers local economies and reduces dependency on external contractors.

2.3 Target Markets and Customer Segments for Distributors

Interlocking soil brick machines appeal to distinct customer segments, each with unique needs and purchasing drivers. Distributors who tailor their offerings to these segments can maximize sales and customer satisfaction.

2.3.1 Rural Communities and Micro-Entrepreneurs

This is the largest customer segment, consisting of small-scale brick makers, farmers, and community groups in rural areas:

- Budget: $300-$1,500 USD. Prioritize low upfront cost, portability, and manual operation (no electricity).

- Needs: Compatibility with local soil types, ease of operation, and low maintenance. Target production: 500-2,000 bricks/day.

- Market Regions: Rural Africa (Kenya, Nigeria, Tanzania), Asia (India, Bangladesh, Nepal), and Latin America (Peru, Bolivia, Guatemala).

- Selling Strategy: Emphasize cost savings, job creation, and on-site production. Offer starter kits (mold, sieve, mixing tool) and basic training. Partner with local cooperatives to distribute machines and provide ongoing support.

2.3.2 Affordable Housing Developers and NGOs

Developers and NGOs focused on low-cost housing, disaster relief, and community development form a critical institutional segment:

- Budget: $1,000-$5,000 USD per machine. Purchase in bulk (5+ machines) for large-scale projects.

- Needs: High production capacity (300+ bph), durability, and compatibility with diverse soil types. Prioritize social impact and sustainability.

- Market Regions: Disaster-prone areas (Haiti, Philippines, Nepal), urban informal settlements (Kenya’s Kibera, India’s Dharavi), and rural development zones.

- Selling Strategy: Highlight affordable housing cost reductions, carbon footprint reduction, and community empowerment. Provide technical support, training programs for construction workers, and bulk pricing discounts. Partner with international organizations (UN Habitat, World Bank) to secure project-based orders.

2.3.3 Eco-Tourism and Sustainable Construction Firms

Eco-tourism resorts, green building contractors, and architects specializing in sustainable design are a growing niche segment:

- Budget: $2,000-$8,000 USD. Willing to pay premium for semi-automatic machines with advanced features (moisture control, custom molds).

- Needs: Aesthetic flexibility (decorative brick designs), high brick quality (6-8 MPa strength), and compliance with green building standards (LEED, BREEAM).

- Market Regions: Costa Rica, Bali, South Africa, and eco-conscious markets in Europe and North America.

- Selling Strategy: Emphasize sustainability credentials (zero carbon emissions, local material use), architectural versatility (custom molds for decorative bricks), and natural insulation benefits. Provide case studies of eco-tourism projects using soil bricks to enhance credibility.

2.3.4 Government Agencies and Public Works Departments

Government bodies implementing rural development, affordable housing, and infrastructure projects are valuable bulk purchasers:

- Budget: $1,500-$6,000 USD per machine. Purchase 10+ machines for regional development programs.

- Needs: Durability, scalability, and compliance with local building codes. Prioritize cost savings for public projects.

- Market Regions: Emerging economies with active affordable housing initiatives (India, Kenya, Brazil, Indonesia).

- Selling Strategy: Highlight cost savings for public budgets, job creation, and alignment with national sustainability goals. Offer tender support, technical documentation (certified brick strength tests), and long-term maintenance contracts. Partner with local distributors to meet government procurement requirements.

2.4 Procurement and Distribution Strategies for Profitability

For distributors and purchasers, successful procurement and distribution of interlocking soil brick machines require strategic planning to ensure quality, minimize costs, and reach target customers effectively.

2.4.1 Sourcing Reliable Suppliers

Selecting the right supplier is critical to securing high-quality machines optimized for soil brick production:

- Manufacturer Criteria: Prioritize suppliers with 3+ years of experience in soil brick machine production (not general brick machine manufacturers). Look for ISO 9001 certification and compliance with safety standards (CE, ASTM). Request soil brick samples produced by the machine to test strength and durability.

- Quality Control Checks: Inspect sample machines for:

- Frame rigidity (no bending during compaction).

- Mold precision (consistent brick size, tight interlocking fit).

- Compaction efficiency (ability to achieve 1.8+ g/cm³ brick density).

- Ease of operation (lever force <30 kg, mold release without brick damage).

- Supplier Support: Ensure suppliers offer:

- Detailed soil preparation and operation manuals (with illustrations for low-literacy users).

- Spare parts (molds, compaction plates, wear inserts) at affordable prices.

- Technical support via phone/WhatsApp (critical for remote areas).

- Minimum Order Quantities (MOQs): Most manufacturers require MOQs of 5-10 machines for wholesale pricing. For small distributors, join forces with other local distributors to meet MOQs and secure 10-15% volume discounts.

2.4.2 Pricing and Margin Optimization

Setting competitive prices while maintaining profitability requires understanding cost structures and market willingness to pay:

- Cost Structure Breakdown: Calculate total cost per machine, including:

- Supplier price (FOB/CIF): $200-$5,000 USD (manual to semi-automatic).

- Shipping and import duties: 10-40% of CIF value (varies by country).

- Local transportation and storage: $50-$200 USD per machine.

- Training and after-sales support: $30-$100 USD per machine.

- Pricing Strategy:

- Manual lever models: Retail price $300-$800 USD (30-50% markup).

- Screw-driven models: $800-$1,800 USD (35-55% markup).

- Hydraulic semi-automatic models: $1,800-$8,000 USD (40-60% markup).

- Bulk orders (5+ machines): Offer 10-15% discounts to institutional customers.

- Value-Added Services to Boost Margins:

- Custom molds for decorative bricks: $100-$300 USD per set.

- Soil testing kits (to analyze local soil suitability): $50-$150 USD.

- Training workshops for community groups: $100-$200 USD per session.

- Maintenance contracts (1-2 years): $50-$150 USD per year.

2.4.3 Distribution Channel Optimization

Reaching target customers requires channels that align with their location, budget, and purchasing behavior:

- Direct Sales: Sell directly to institutional customers (NGOs, government agencies) via online platforms (Alibaba, LinkedIn), trade shows (Bauma, CONEXPO), and direct outreach. Direct sales maximize margins (30-60%) and allow for customized solutions.

- Local Partner Distribution: Collaborate with local hardware stores, agricultural cooperatives, and construction supply retailers in rural areas. Offer retailers a 15-25% commission, along with training and marketing materials (posters, videos in local languages).

- Community-Based Distribution: Partner with local NGOs, community development organizations, and women’s cooperatives to distribute machines in remote areas. These partners have trusted relationships with rural communities and can facilitate training and adoption.

- Demonstration-Driven Sales: Conduct on-site demonstrations in target communities to showcase the machine’s ease of use and brick quality. Demonstrations are highly effective in regions where customers prefer to test products before purchasing.

2.4.4 After-Sales Support and Customer Retention

Effective after-sales support is critical to building customer loyalty and generating repeat business:

- Training: Provide hands-on training (1-2 days) for operators, covering soil preparation, machine operation, brick curing, and basic maintenance. For rural customers, use visual aids (illustrations, videos) and local language instructors.

- Spare Parts Availability: Stock common spare parts (molds, wear inserts, lubricants) locally to reduce delivery time. For remote areas, partner with local mechanics to stock and sell spare parts.

- Technical Support: Offer a dedicated phone line or WhatsApp number for troubleshooting. For complex issues, provide video call support or dispatch a technician (for institutional customers).

- Customer Feedback Loops: Regularly follow up with customers (1 month, 6 months post-purchase) to gather feedback, address issues, and share best practices (e.g., soil amendment techniques, curing methods). Satisfied customers are likely to refer others and purchase additional machines for scaling operations.

2.5 Market Trends and Future Opportunities for Interlocking Soil Brick Machines

The market for interlocking soil brick machines is growing rapidly, driven by global sustainability goals, affordable housing demand, and technological advancements. Distributors who stay ahead of these trends can capitalize on emerging opportunities.

2.5.1 Growing Demand for Sustainable and Circular Construction

The global push for net-zero carbon construction is driving demand for low-carbon building materials and equipment:

- Policy Support: Governments worldwide are implementing carbon taxes, green building mandates, and subsidies for sustainable construction. For example, India’s Green Building Council offers incentives for projects using local, low-carbon materials like soil bricks.

- Corporate Sustainability Goals: Construction firms and real estate developers are committing to net-zero carbon portfolios, creating demand for soil brick machines as a low-carbon alternative to concrete.

- Opportunity: Market interlocking soil brick machines as “carbon-negative construction solutions,” emphasizing their zero-emission production and local resource use. Obtain green certifications (e.g., ECOLOGO, Green Seal) to enhance credibility with eco-conscious customers.

2.5.2 Technological Advancements for Soil Brick Machines

Manufacturers are incorporating minor technological improvements to enhance performance without increasing complexity:

- Moisture Sensing and Control: Advanced models include sensors that measure soil moisture and automatically adjust water addition, ensuring optimal compaction and brick quality. This feature is valuable for customers with variable soil types.

- Electric-Powered Semi-Automatic Models: Small, battery-powered (12V/24V) semi-automatic machines are emerging, offering higher production capacity (300-400 bph) without relying on grid electricity. These machines are ideal for remote areas with limited power access.

- Custom Mold Technology: 3D-printed molds are becoming more affordable, allowing for complex, decorative interlocking designs. This expands the market to eco-tourism and high-end sustainable housing projects.

- Opportunity: Offer these advanced models at a 20-30% premium, targeting institutional customers and eco-tourism developers who value performance and versatility.

2.5.3 Expansion into Disaster Relief and Resilient Construction

Interlocking soil brick machines are ideal for post-disaster reconstruction, as they:

- Can be quickly deployed to remote areas with no power.

- Use local soil, eliminating the need for imported building materials.

- Produce durable, seismic-resistant bricks.

- Opportunity: Partner with humanitarian organizations (Red Cross, UNICEF, ShelterBox) to supply machines for disaster relief efforts. These partnerships can drive bulk sales and enhance brand visibility.

2.5.4 Niche Market Growth: Eco-Tourism and Green Housing

Eco-tourism resorts and green housing developments are increasingly using soil bricks for their aesthetic, sustainability, and insulation benefits:

- Aesthetic Appeal: Soil bricks offer a natural, earthy appearance that aligns with eco-tourism design themes. Custom molds allow for unique textures and patterns, enhancing architectural value.

- Insulation Benefits: Soil bricks provide natural thermal insulation, reducing energy costs for heating and cooling—critical for eco-tourism resorts in tropical or arid climates.

- Opportunity: Develop specialized models for eco-tourism, with custom molds for decorative bricks and semi-automatic operation for higher production. Partner with architects and eco-tourism developers to showcase soil brick projects.

3. Conclusion

Interlocking soil brick machines represent a transformative solution in the global construction industry—combining affordability, sustainability, and social impact to address critical challenges like affordable housing shortages, climate change, and rural unemployment. For distributors, distributors, and purchasers, these machines offer a high-growth, low-risk product category that aligns with market demands and global goals. By understanding the soil-specific design and engineering of these machines, distributors can effectively communicate their value propositions, target the right customer segments, and implement procurement and distribution strategies that maximize profitability.

The unique advantages of interlocking soil brick machines—local soil utilization, zero carbon emissions, cost savings, and community empowerment—make them indispensable for rural development, affordable housing, eco-tourism, and disaster relief projects. As the world shifts toward sustainable construction, the demand for these machines will continue to grow, creating significant opportunities for industry professionals who adapt to market trends and prioritize customer needs.

For purchasers, interlocking soil brick machines offer a cost-effective, reliable solution for small-scale to medium-scale brick production, with quick ROI and minimal environmental impact. For distributors, they represent a chance to build profitable businesses while contributing to positive social and environmental change. In a world where sustainability and accessibility are increasingly important, interlocking soil brick machines are more than just construction equipment—they are tools for building inclusive, resilient, and sustainable communities.

4. FAQ

4.1 What types of soil are suitable for interlocking soil brick machines?

Interlocking soil brick machines work best with loamy soil (40-60% sand, 20-40% silt, 10-20% clay) or clay-loam soil (20-30% clay). Sandy soils require 5-10% clay or 2-5% lime/cement as a binder to improve cohesion. Heavy clay soils need 10-15% sand to reduce shrinkage and cracking. Soil should be free of rocks, roots, and debris (sieved through a 5-10 mm mesh) for optimal performance.

4.2 What is the compressive strength of interlocking soil bricks?

Interlocking soil bricks have a compressive strength of 2-8 MPa, depending on soil type, compaction pressure, and binder addition:

- Pure soil bricks (high clay content): 2-4 MPa (suitable for non-load-bearing walls, landscaping).

- Soil + 2-3% lime/cement: 4-6 MPa (suitable for low-rise load-bearing walls, 1-2 stories).

- Soil + 4-5% lime/cement: 6-8 MPa (compliant with local building codes in most emerging economies).

4.3 How much does an interlocking soil brick machine cost, and what is the ROI?

Interlocking soil brick machines range in price from $300-$8,000 USD:

- Manual lever models: $300-$800 USD.

- Screw-driven models: $800-$1,800 USD.

- Hydraulic semi-automatic models: $1,800-$8,000 USD.ROI is typically 4-12 months, based on:

- Production cost: $0.02-$0.05 per brick (soil + 2-5% binder).

- Selling price: $0.10-$0.25 per brick (varies by region).

- Production volume: 500-2,000 bricks/day (small-scale operations).

4.4 How durable are interlocking soil bricks, and how long do they last?

With proper compaction, binder addition (2-5% lime/cement), and curing (14-28 days), interlocking soil bricks are highly durable:

- Lifespan: 50-100 years, comparable to concrete bricks.

- Weather resistance: Resistant to rain, wind, and temperature fluctuations. In humid climates, apply a lime wash or waterproof coating to prevent moisture absorption.

- Seismic resistance: Interlocking designs improve wall stability, with soil brick walls tested to withstand seismic activity up to 6.5 magnitude.

4.5 Can interlocking soil brick machines be used for large-scale construction projects?

Yes, semi-automatic hydraulic interlocking soil brick machines are suitable for large-scale projects (e.g., affordable housing estates, schools, clinics) with production capacities of 300-600 bricks/hour. For projects requiring 10,000+ bricks/day, multiple machines can be deployed in a production line. Soil bricks have been used in large-scale projects like the 1,000-unit affordable housing development in Kenya’s Kilifi County and the post-earthquake reconstruction in Nepal.

4.6 What maintenance is required for an interlocking soil brick machine?

Maintenance requirements are minimal, with routine tasks including:

- Daily: Clean the mold to remove dried soil and inspect for debris. Lubricate moving parts (hinges, screws) with oil or grease.

- Weekly: Check the frame for cracks or loose bolts. Tighten any loose components and replace worn mold inserts if needed.

- Monthly: Inspect the compaction mechanism (lever, screw, or hydraulic system) for wear. For hydraulic models, check oil levels and replace filters.Total annual maintenance costs are typically $50-$150 USD, with no need for specialized tools or technical expertise.

4.7 Are interlocking soil bricks compliant with local building codes?

In most emerging economies (Kenya, India, Nigeria, Brazil), interlocking soil bricks with 4-5% binder meet local building codes for low-rise (1-2 story) load-bearing structures. For higher-rise buildings or projects in developed countries, soil bricks are commonly used for non-load-bearing walls, landscaping, and eco-friendly additions. Distributors should provide customers with brick strength test reports (from certified laboratories) to facilitate code compliance.

4.8 How portable are interlocking soil brick machines, and how are they transported?

Interlocking soil brick machines are highly portable, with:

- Weight: 100-250 kg (manual models) to 500-800 kg (semi-automatic hydraulic models).

- Dimensions: 1.2×1.0x1.5 meters (manual) to 2.0×1.5×2.0 meters (semi-automatic).Transport options include:

- Pickup trucks, vans, or small lorries for medium-distance transport.

- Motorcycles or animal-drawn carts for short distances in rural areas.

- Hand-carrying by 3-4 people for remote sites with no vehicle access.Most manual models feature foldable handles or detachable components to enhance portability.