1. Giriş

In the global construction industry, the demand for efficient, cost-effective, and reliable building materials production equipment continues to soar. Among these, machines designed for brick making stand out as indispensable assets, catering to the growing need for high-quality bricks in residential, commercial, and infrastructure projects.

2. Core Fundamentals of Brick Making Machines

2.1 Definition and Classification

A brick making machine is a mechanical device engineered to produce standardized bricks from various raw materials such as clay, concrete, fly ash, sand, and lime. Unlike traditional manual brick-making methods, these machines automate the entire production process—from raw material mixing and molding to compaction and curing—ensuring consistency, efficiency, and scalability. Based on their operational mechanism, output capacity, and application scope, machines for brick making can be classified into several key categories:

- Manual Brick Making Machines: Compact, low-cost units operated manually or with minimal power. Ideal for small-scale projects, rural areas, or regions with limited electricity access. Output ranges from 500 to 2000 bricks per day.

- Semi-Automatic Brick Making Machines: Combine manual feeding with automated compaction and molding. Require 1-2 operators and offer a balance between cost and efficiency. Output typically ranges from 2000 to 10,000 bricks per day. Suitable for medium-scale distributors serving local construction firms.

- Automatic Brick Making Machines: Fully automated systems with conveyor belts for raw material feeding, hydraulic or mechanical compaction, and automatic brick stacking. Operate with minimal human intervention, offering high output (10,000 to 50,000+ bricks per day) and consistent quality. Designed for large-scale distributors, wholesalers, or purchasers supplying major construction projects.

- Mobile Brick Making Machines: Portable units that can be transported to construction sites, eliminating the need for brick transportation. Equipped with wheels or a trailer, these machines are powered by diesel engines or electric motors, making them suitable for remote locations or projects with urgent brick requirements.

2.2 Key Components and Working Principles

Regardless of the type, all brick making machines share core components that drive their functionality. Understanding these components is crucial for distributors and purchasers to assess machine durability, maintenance needs, and performance:

- Raw Material Hopper: Stores and feeds raw materials (e.g., clay, concrete mix) into the mixing unit. Designed with adjustable feeding rates to control the consistency of the brick mixture.

- Mixing Unit: Blends raw materials with water (or other additives) to form a homogeneous mixture. High-quality mixing units feature spiral blades or paddles for thorough mixing, ensuring uniform density in the final bricks.

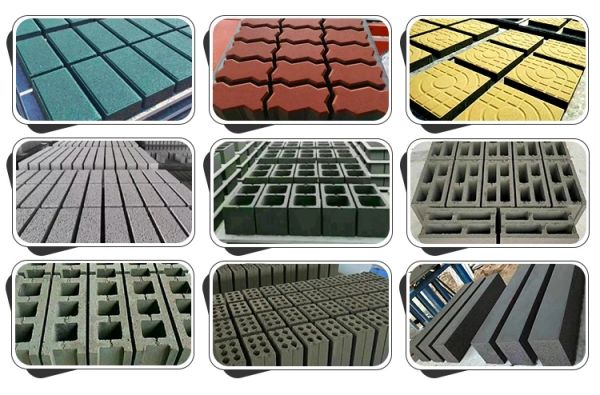

- Molding System: The heart of the machine, responsible for shaping the brick mixture into the desired size and form. Molds are interchangeable, allowing production of different brick types (e.g., solid bricks, hollow bricks, interlocking bricks) by simply changing the mold design.

- Compaction Mechanism: Applies pressure to the mold to compress the brick mixture, enhancing its strength and durability. Compaction can be hydraulic (for high pressure and precision) or mechanical (cost-effective for small-scale machines). Hydraulic systems are preferred for automatic machines, as they offer consistent pressure control and higher compaction force.

- Curing System: Some advanced machines include integrated curing chambers or drying racks to accelerate the brick hardening process. Curing is critical for achieving the required compressive strength—bricks cured properly can withstand higher loads and resist weathering.

- Control Panel: Found in semi-automatic and automatic machines, the control panel allows operators to adjust parameters such as mixing time, compaction pressure, and production speed. Modern machines feature digital displays and programmable logic controllers (PLCs) for precise operation and troubleshooting.

The working principle of a brick making machine follows a sequential process: (1) Raw materials are loaded into the hopper and fed into the mixing unit; (2) The mixture is blended with water to the optimal moisture content; (3) The homogeneous mixture is transferred to the molding system; (4) The compaction mechanism applies pressure to the mold, shaping the brick; (5) The molded brick is ejected from the mold and moved to the curing area; (6) Cured bricks are stacked for storage or transportation. This automated process reduces human error, increases production speed, and ensures consistent brick quality—key selling points for distributors targeting construction clients.

3. Market Demand and Business Value for Distributors & Purchasers

3.1 Global Market Trends Driving Growth

The brick making machine market is experiencing steady growth, driven by several key trends that present lucrative opportunities for distributors, wholesalers, and purchasers:

- Booming Construction Industry: Rapid urbanization, infrastructure development, and housing projects in emerging economies (e.g., India, China, Brazil, and Southeast Asian countries) are fueling demand for bricks. According to industry reports, the global construction sector is projected to grow at a CAGR of 5-7% over the next decade, directly increasing the need for efficient brick production equipment.

- Shift Towards Sustainable Construction: Governments and construction firms worldwide are prioritizing eco-friendly building materials. Brick making machines that use recycled materials (e.g., fly ash, construction waste) or reduce energy consumption are in high demand. Distributors offering sustainable machine options can tap into this growing niche market, appealing to clients seeking green construction solutions.

- Labor Shortages and Cost Reduction: Traditional manual brick making is labor-intensive and time-consuming, with rising labor costs in many regions. Brick making machines automate the process, reducing reliance on manual labor and lowering production costs for construction firms. This cost-saving benefit makes machines for brick making a valuable investment for clients, driving demand for distributors who supply reliable equipment.

- Infrastructure Development Initiatives: Governments in developing and developed countries are launching large-scale infrastructure projects (e.g., roads, bridges, airports, affordable housing) to stimulate economic growth. These projects require massive quantities of bricks, creating a sustained demand for high-capacity brick making machines. Distributors and purchasers who align their product offerings with these initiatives can secure long-term business partnerships.

3.2 Profitability and Competitive Advantages for Distributors

For distributors and wholesalers, adding brick making machines to their product portfolio offers significant profitability and competitive advantages:

- High Margins: Brick making machines have a favorable profit margin, especially for semi-automatic and automatic models. Since the equipment is a capital good, clients are willing to invest in high-quality machines, allowing distributors to mark up prices while maintaining competitiveness.

- Repeat Business and After-Sales Revenue: Brick making machines require regular maintenance, spare parts replacement, and technical support. Distributors who offer comprehensive after-sales services (e.g., maintenance contracts, spare parts supply, training) can generate recurring revenue and build long-term client relationships.

- Diversification: The construction equipment market is diverse, but brick making machines cater to a specific, high-demand segment. Distributors who diversify their product lines with these machines can reduce reliance on a single product category and tap into new customer bases (e.g., small construction firms, brick manufacturers, government contractors).

- Low Inventory Turnover Risk: Brick making machines are durable and have a long shelf life, reducing the risk of inventory obsolescence. Unlike consumer goods, which have short product cycles, brick making machines retain their value for years, allowing distributors to hold inventory without significant depreciation losses.

3.3 Value Propositions for Purchasers

Purchasers (e.g., brick manufacturers, construction firms, government agencies) benefit from investing in high-quality brick making machines in multiple ways:

- Increased Production Efficiency: Automated and semi-automated machines significantly boost brick production capacity compared to manual methods. For example, an automatic machine can produce 50,000 bricks per day, while manual labor can only produce 500-1000 bricks per day. This efficiency allows purchasers to meet tight project deadlines and fulfill large orders.

- Consistent Quality: Machine-made bricks have uniform size, shape, and compressive strength, meeting industry standards and building codes. Consistent quality reduces rejections and ensures the structural integrity of construction projects, enhancing the purchaser’s reputation.

- Cost Savings: While the initial investment in a brick making machine is higher than manual labor, the long-term cost savings are substantial. Machines reduce labor costs, minimize raw material waste (due to precise mixing and molding), and lower transportation costs (especially for mobile machines). Purchasers can recover their investment within 6-18 months, depending on usage and output.

- Flexibility and Customization: Interchangeable molds allow purchasers to produce different brick types and sizes to meet diverse client needs. Whether it’s solid bricks for load-bearing walls, hollow bricks for insulation, or interlocking bricks for landscaping, brick making machines offer versatility that manual methods cannot match.

4. Technical Specifications and Performance Metrics to Evaluate

4.1 Critical Specifications for Distributors & Purchasers

When selecting or supplying brick making machines, distributors and purchasers must evaluate key technical specifications to ensure the equipment meets client requirements. The following metrics are critical for assessing performance, durability, and suitability:

- Output Capacity: Measured in bricks per day (or per hour). This is the most important specification for clients, as it determines the machine’s ability to meet production demands. Distributors should match the machine’s output to the client’s project scale—small-scale clients may need 1000-5000 bricks per day, while large-scale manufacturers require 20,000+ bricks per day.

- Brick Size and Type: Machines should support standard brick sizes (e.g., 230x115x75mm, 240x120x80mm) and customizable sizes via interchangeable molds. Clients may also require machines that produce specific brick types (hollow, solid, interlocking), so distributors should confirm mold compatibility.

- Raw Material Compatibility: Different machines are designed for specific raw materials (clay, concrete, fly ash, etc.). Distributors must ensure the machine can handle the raw materials available in the client’s region. For example, fly ash brick making machines are ideal for regions with abundant fly ash (a byproduct of coal-fired power plants), while clay brick machines are suitable for areas with clay deposits.

- Power Requirement: Measured in kilowatts (kW) for electric machines or horsepower (HP) for diesel-powered units. Clients need to know the power consumption to assess operational costs and ensure compatibility with their power supply. Automatic machines typically require 10-30 kW, while manual machines may use 1-5 kW.

- Compaction Pressure: Expressed in megapascals (MPa), compaction pressure determines the strength of the bricks. Higher pressure (15-30 MPa) results in stronger bricks with higher compressive strength (e.g., 10-25 N/mm²). Clients in construction projects requiring high-strength bricks (e.g., load-bearing walls) will prioritize machines with higher compaction pressure.

- Dimensions and Weight: Important for transportation and installation. Mobile machines should be compact and lightweight for easy mobility, while stationary automatic machines may require dedicated floor space. Distributors should provide detailed dimensions to help clients plan their facility layout.

- Durability and Material Quality: The machine’s frame, components, and molds should be made of high-quality materials (e.g., steel, cast iron) to withstand heavy usage and harsh working conditions. Molds should be wear-resistant, as frequent mold replacement can increase operational costs for clients.

4.2 Performance Testing and Quality Assurance

To ensure the reliability of brick making machines, distributors and purchasers should verify that the equipment undergoes rigorous performance testing and quality assurance processes. Key testing parameters include:

- Brick Compressive Strength: Samples of bricks produced by the machine should be tested for compressive strength using a universal testing machine. The results should meet industry standards (e.g., IS 1077 for clay bricks, IS 2185 for concrete bricks).

- Production Consistency: The machine should produce bricks of uniform size, shape, and weight. Variations in dimensions should be within ±2mm, as inconsistent bricks can cause problems during construction (e.g., uneven walls).

- Energy Efficiency: The machine’s power consumption should be within the specified range, with no excessive energy waste. Energy-efficient machines reduce operational costs for clients and align with sustainable construction trends.

- Noise and Vibration Levels: Excessive noise and vibration can affect operator comfort and machine durability. Machines should comply with noise standards (e.g., <85 dB) and be equipped with vibration-damping components.

- Safety Features: The machine should have safety guards, emergency stop buttons, and overload protection to prevent accidents. Safety is a critical consideration for clients, as it reduces liability and ensures compliance with labor regulations.

5. Installation, Operation, and Maintenance Guidelines

5.1 Installation Requirements

Proper installation is essential for the optimal performance and longevity of brick making machines. Distributors should provide detailed installation guidelines to clients, or offer installation services as part of the package. Key installation steps include:

- Site Preparation: The installation site should be flat, level, and spacious enough to accommodate the machine, raw materials, and finished bricks. For stationary machines, a concrete foundation may be required to support the machine’s weight and reduce vibration.

- Power Supply Connection: Ensure the power supply matches the machine’s voltage and current requirements. Use high-quality cables and circuit breakers to prevent electrical issues. Diesel-powered machines should be installed in well-ventilated areas to avoid exhaust fumes accumulation.

- Machine Assembly: Follow the manufacturer’s instructions to assemble the machine components (hopper, mixing unit, molding system, control panel). Ensure all bolts and fasteners are tightened securely, and moving parts are lubricated properly.

- Mold Installation: Install the desired mold correctly, ensuring alignment with the compaction mechanism. Test the mold by producing a few sample bricks to check for proper shaping and size.

- Calibration: Calibrate the machine’s parameters (mixing time, compaction pressure, feeding rate) according to the raw material type and brick specifications. Calibration ensures consistent production and optimal performance.

5.2 Operation Best Practices

To maximize productivity and minimize downtime, operators should follow these operation best practices:

- Ham Madde Hazırlama: Ensure raw materials are clean, dry, and free from impurities (e.g., stones, debris) that can damage the machine or affect brick quality. The moisture content of the mixture should be controlled—too much water can cause bricks to crack, while too little water reduces compaction efficiency.

- Regular Monitoring: Monitor the machine’s operation continuously, checking for unusual noise, vibration, or leaks. Use the control panel to track production metrics (output, compaction pressure) and adjust parameters as needed.

- Operator Training: Ensure operators are trained on the machine’s functions, safety features, and troubleshooting procedures. Proper training reduces the risk of accidents and machine damage, and improves production efficiency.

- Batch Processing: For large-scale production, use batch processing to maintain consistency. Measure raw materials accurately for each batch, and avoid overloading the machine beyond its capacity.

5.3 Maintenance and Troubleshooting

Regular maintenance is critical to extend the machine’s lifespan and prevent costly breakdowns. Distributors should provide clients with a maintenance schedule and troubleshooting guide, including:

- Daily Maintenance: Clean the machine after use, remove residual raw materials from the hopper and mold, and check for loose bolts or fasteners. Lubricate moving parts (e.g., bearings, gears) with the recommended lubricant.

- Weekly Maintenance: Inspect the mold for wear and tear, replace if necessary. Check the hydraulic system (for hydraulic machines) for leaks and ensure proper oil levels. Clean the air filters and cooling system.

- Monthly Maintenance: Inspect the electrical system (wiring, motors, control panel) for damage. Test the safety features (emergency stop button, overload protection) to ensure they are functioning properly. Calibrate the machine’s parameters if needed.

- Common Troubleshooting Issues:

- Bricks cracking or breaking: Possible causes include insufficient compaction pressure, improper moisture content, or mold damage. Solutions: Adjust compaction pressure, control raw material moisture, replace worn molds.

- Low production output: Possible causes include clogged hopper, inefficient mixing, or power supply issues. Solutions: Clean the hopper, check the mixing unit, verify power supply.

- Machine jamming: Possible causes include foreign objects in the machine, misaligned mold, or overloading. Solutions: Stop the machine, remove foreign objects, realign the mold, reduce load.

6. Conclusion

Brick making machines are essential equipment in the modern construction industry, offering efficiency, consistency, and cost savings that manual methods cannot match. For distributors, wholesalers, and purchasers, these machines represent a lucrative business opportunity, driven by global construction growth, sustainable building trends, and labor cost reductions. By understanding the core fundamentals, technical specifications, market demand, and operational guidelines outlined in this guide, stakeholders can make informed decisions—whether expanding product portfolios, sourcing equipment for clients, or investing in production capacity.

Key takeaways for distributors include the importance of offering a range of machine types to cater to different client scales, providing comprehensive after-sales services to generate recurring revenue, and aligning product offerings with sustainable construction trends. For purchasers, the focus should be on evaluating technical specifications (output capacity, compaction pressure, raw material compatibility) to match project requirements, prioritizing quality and durability to ensure long-term value, and following proper installation and maintenance practices to maximize machine performance.

As the construction industry continues to evolve, brick making machines will remain a critical component of building material production. By staying informed about market trends, technical advancements, and client needs, distributors, wholesalers, and purchasers can capitalize on the growing demand for these machines and build successful, sustainable businesses in the construction equipment supply chain.

7. FAQ (Frequently Asked Questions)

7.1 What is the typical lifespan of a brick making machine?

The lifespan of a brick making machine depends on the type, quality of components, and maintenance practices. Manual machines typically last 5-8 years, semi-automatic machines 8-12 years, and automatic machines 12-15 years (or longer with proper maintenance). Regular lubrication, mold replacement, and electrical system checks can extend the machine’s lifespan significantly.

7.2 Can a single brick making machine produce different types of bricks?

Yes, most brick making machines support interchangeable molds, allowing production of different brick types (solid, hollow, interlocking) and sizes. Distributors should confirm the number of mold options available for each machine model, as some manufacturers offer custom mold designs to meet specific client requirements.

7.3 What raw materials can be used in a brick making machine?

Brick making machines can process a variety of raw materials, including clay, concrete (cement + sand + aggregate), fly ash, lime, gypsum, and recycled construction waste. The choice of raw material depends on the machine’s design—some machines are specialized for clay, while others are designed for concrete or fly ash. Distributors should advise clients to use raw materials that are locally available and meet industry standards for brick production.

7.4 How much space is required to install a brick making machine?

Space requirements vary by machine type:

- Manual machines: 10-20 square meters (small, portable units)

- Semi-automatic machines: 30-50 square meters (includes space for raw materials and finished bricks)

- Automatic machines: 100-200+ square meters (requires space for conveyor belts, curing area, and storage)Mobile machines require minimal fixed space, as they can be moved to different locations.

7.5 What is the average power consumption of a brick making machine?

Power consumption depends on the machine’s size and type:

- Manual machines: 1-5 kW/hour

- Semi-automatic machines: 5-10 kW/hour

- Automatic machines: 10-30 kW/hourDiesel-powered mobile machines consume 5-15 liters of diesel per hour, depending on output capacity. Clients should factor in power costs when calculating operational expenses.

7.6 Do brick making machines require specialized training to operate?

Semi-automatic and automatic machines require basic training to operate, as they involve control panels, parameter adjustment, and safety procedures. Manual machines are simpler to operate but still require training on raw material preparation and mold handling. Distributors should offer training services (on-site or online) to clients, or provide detailed operation manuals to ensure safe and efficient use.

7.7 What after-sales services should distributors provide for brick making machines?

Distributors should offer the following after-sales services to enhance customer satisfaction and generate repeat business:

- Installation support (on-site or remote)

- Operator training

- Spare parts supply (molds, bearings, hydraulic components, etc.)

- Maintenance contracts (regular servicing and repairs)

- Technical support (phone, email, or video call troubleshooting)

- Warranty coverage (typically 1-2 years for machine components, excluding wear-and-tear parts like molds)

7.8 What is the lead time for ordering a brick making machine?

Lead time varies by manufacturer and machine type. Manual and semi-automatic machines typically have a lead time of 2-4 weeks, while automatic machines may take 4-8 weeks (or longer for custom configurations). Distributors should communicate accurate lead times to clients to avoid delays in project timelines.