1. Giới thiệu

The intersection of “brick block machine maker” and “brick block machine for sale” forms the backbone of the global construction equipment supply chain, connecting manufacturers of industrial-grade machinery with distributors, wholesalers, and purchasers seeking reliable, high-performance production solutions. For B2B stakeholders, navigating this landscape requires two critical skills: identifying reputable brick block machine makers that prioritize quality, innovation, and scalability, and selecting “for sale” models that align with market demand, client needs, and profitability goals.

2. Evaluating Brick Block Machine Makers: Key Criteria for B2B Stakeholders

2.1 Core Competencies of Reputable Makers

Not all brick block machine makers are created equal—reliable manufacturers distinguish themselves through specific competencies that directly impact the quality, durability, and marketability of their “for sale” machines. Distributors, wholesalers, and purchasers should prioritize makers with the following attributes:

- Engineering and R&D Capabilities: Leading makers invest in research and development to improve machine performance, energy efficiency, and versatility. Look for makers with in-house engineering teams that design proprietary components (e.g., hydraulic systems, PLC control panels) and adapt machines to regional needs (e.g., raw material compatibility, power standards). Makers with patents or certifications (e.g., ISO 9001 for quality management, CE for safety) demonstrate a commitment to innovation and compliance.

- Manufacturing Quality Control: Reputable makers implement strict quality control (QC) processes throughout production—from raw material sourcing (e.g., high-grade steel for frames, wear-resistant alloys for molds) to final assembly and testing. Key QC measures include:

- Component inspection (e.g., hydraulic hoses, motors, molds) for defects.

- Performance testing (e.g., production capacity, compaction pressure, brick strength).

- Durability testing (e.g., 1,000+ hours of continuous operation) to ensure machines withstand industrial use.

- Customization Flexibility: Top makers offer customization options to tailor “for sale” machines to specific markets or client needs. This includes:

- Interchangeable molds for different brick/block sizes (e.g., standard, hollow, interlocking).

- Power configuration adjustments (e.g., electric, diesel, dual-power) for regions with varying infrastructure.

- Integration with auxiliary equipment (e.g., batching systems, curing chambers, robotic stackers) to create full production lines.

- Global Supply Chain and Production Capacity: Makers with robust production facilities and global supply chains can meet large “for sale” orders (e.g., 50+ machines for distributors) and deliver within reasonable lead times (4-8 weeks for standard models, 8-12 weeks for custom configurations). Look for makers with multiple manufacturing sites or strategic partnerships to reduce shipping costs and delivery delays.

- After-Sales Support Infrastructure: Reliable makers provide comprehensive after-sales support to B2B stakeholders, including:

- Warranty coverage (1-2 years for machine components, 6 months for wear parts like molds).

- Spare parts supply (local warehouses or fast shipping) to minimize downtime for purchasers.

- Technical training (on-site or virtual) for distributors, wholesalers, and end-users.

- 24/7 technical support via phone, email, or video call for troubleshooting.

2.2 Red Flags to Avoid When Vetting Makers

When evaluating brick block machine makers for “for sale” partnerships, B2B stakeholders should be wary of the following red flags:

- Lack of Transparency: Makers unwilling to share production facilities, QC processes, or client references are likely hiding quality issues. Avoid makers that refuse to provide sample machines or brick test reports.

- Inconsistent Lead Times: Makers with unpredictable delivery timelines (e.g., promising 4 weeks but delivering in 12) can disrupt your “for sale” inventory and customer relationships.

- Poor Component Quality: Makers using low-grade materials (e.g., thin steel frames, plastic gears) produce machines that fail prematurely. Inspect sample machines for flimsy construction, uneven welds, or low-quality molds.

- Limited Customization: Makers that only offer one-size-fits-all machines cannot adapt to regional market needs (e.g., different brick sizes, power standards), limiting your “for sale” appeal.

- Non-Existent After-Sales Support: Makers that do not offer warranties, spare parts, or technical support leave distributors and purchasers responsible for costly repairs and downtime.

2.3 Maker-Tier Classification: Aligning with Your Business Goals

Brick block machine makers can be classified into three tiers based on their capabilities, pricing, and target markets. B2B stakeholders should align with makers that match their “for sale” strategy:

2.3.1 Tier 1: Premium Industrial Makers

- Profile: Large-scale manufacturers with global reach, advanced R&D, and premium quality machines. Specialize in fully automatic, high-capacity production lines (10,000+ bricks/day).

- Pricing: $50,000-$500,000+ per machine (depending on capacity and customization).

- Target B2B Stakeholders: Distributors serving large brick manufacturers, wholesalers supplying municipal projects, and purchasers investing in industrial-scale production facilities.

- Key Advantages: Superior quality, advanced technology (e.g., IoT monitoring, servo-electric compaction), and comprehensive after-sales support.

- Use Case: Ideal for “for sale” inventory targeting high-end markets (e.g., Europe, North America, Middle East) where clients prioritize performance and durability.

2.3.2 Tier 2: Mid-Range Commercial Makers

- Profile: Regional or international manufacturers balancing quality and affordability. Offer semi-automatic and entry-level automatic machines (2,000-10,000 bricks/day) with moderate customization.

- Pricing: $10,000-$50,000 per machine.

- Target B2B Stakeholders: Distributors serving medium-scale brick yards, wholesalers targeting regional construction suppliers, and purchasers with mid-sized production needs.

- Key Advantages: Competitive pricing, reliable performance, and faster lead times (3-6 weeks) than Tier 1 makers.

- Use Case: Perfect for “for sale” portfolios targeting emerging markets (e.g., Southeast Asia, Africa, Latin America) where clients seek value without compromising quality.

2.3.3 Tier 3: Budget-Focused Makers

- Profile: Small-scale manufacturers producing manual and basic semi-automatic machines (500-2,000 bricks/day) at low cost.

- Pricing: $1,000-$10,000 per machine.

- Target B2B Stakeholders: Distributors serving rural entrepreneurs, wholesalers supplying small brick yards, and purchasers with limited capital.

- Key Advantages: Low price point, simple design, and no power requirements (for manual models).

- Use Case: Suitable for “for sale” inventory targeting low-income regions (e.g., rural Africa, remote South Asia) where affordability is the primary concern.

3. Optimizing “Brick Block Machine for Sale” Portfolios: B2B Strategy

3.1 Product Segmentation for “For Sale” Success

To maximize sales, distributors and wholesalers should segment their “brick block machine for sale” portfolios to cater to diverse client needs. Key segmentation criteria include:

3.1.1 By Production Capacity

- Mức Khởi Điểm (500-2.000 Viên Gạch/Ngày): Manual and basic semi-automatic machines for small-scale entrepreneurs, rural brick yards, and disaster-relief projects. Price range: $1,000-$5,000.

- Mid-Range (2,000-10,000 Bricks/Day): Semi-automatic and entry-level automatic machines for medium-scale brick manufacturers and regional construction suppliers. Price range: $5,000-$30,000.

- High-Capacity (10,000+ Bricks/Day): Fully automatic production lines for large brick factories, municipal projects, and export markets. Price range: $30,000-$500,000+.

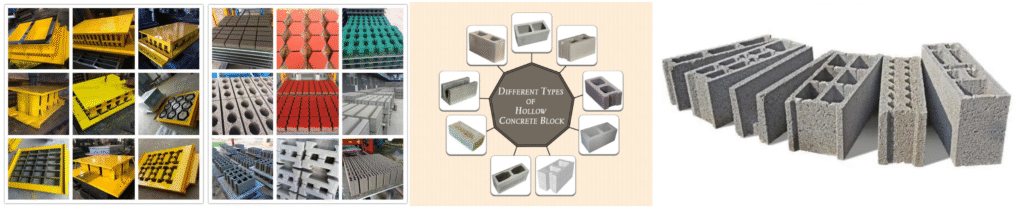

3.1.2 By Machine Type

- Manual Machines: No power required, portable, ideal for remote areas. “For sale” appeal: low cost, simplicity.

- Semi-Automatic Machines: Balance of manual feeding and automated compaction. “For sale” appeal: affordability, moderate efficiency.

- Fully Automatic Machines: Complete automation from batching to stacking. “For sale” appeal: high efficiency, labor savings, consistency.

- Mobile Machines: Portable, on-site production. “For sale” appeal: eliminates brick transportation costs, ideal for remote construction.

3.1.3 By Raw Material Compatibility

- Clay Brick Machines: For regions with abundant clay (e.g., South Asia, Africa). “For sale” appeal: low raw material costs, eco-friendly.

- Concrete Block Machines: For regions with cement and aggregate access (e.g., Europe, North America). “For sale” appeal: high-strength blocks, versatile applications.

- Multi-Material Machines: Process clay, concrete, fly ash, or construction waste. “For sale” appeal: flexibility, sustainability.

3.1.4 By Regional Adaptation

- Developed Markets (Europe, North America): Energy-efficient, low-emission automatic machines with IoT integration. “For sale” appeal: compliance with environmental regulations, smart technology.

- Emerging Markets (Southeast Asia, Africa): Dual-power (electric + diesel), durable semi-automatic machines. “For sale” appeal: adaptability to unstable infrastructure, affordability.

- Remote Regions: Mobile, manual, or diesel-powered machines. “For sale” appeal: no electricity required, portability.

3.2 Pricing Strategy for “For Sale” Machines

Pricing “brick block machine for sale” inventory requires balancing profitability with market competitiveness. Key strategies include:

- Tiered Pricing: Align prices with machine quality and capacity (e.g., Tier 1 automatic machines: 20-30% markup; Tier 3 manual machines: 100-150% markup). Higher margins on low-cost machines compensate for lower sales volume, while lower margins on high-cost machines drive volume.

- Bundling: Offer “for sale” bundles that include the machine, spare parts, training, and a maintenance contract. For example:

- Mid-range semi-automatic machine + 2 extra molds + operator training + 1-year maintenance contract = 15-20% higher price than standalone machine.

- High-capacity automatic line + batching system + curing chamber + robotic stacker = 10% discount compared to purchasing components separately (incentivizes large orders).

- Volume Discounts: Attract wholesalers and large purchasers with volume discounts (e.g., 5% discount for 10+ machines, 10% discount for 20+ machines).

- Regional Pricing Adjustments: Adapt prices to local market conditions (e.g., lower prices in low-income regions, higher prices in developed markets where clients can afford premium features).

- Financing Options: Partner with financial institutions to offer “for sale” financing (e.g., 0% interest for 12 months, lease-to-own) for high-cost automatic machines. This reduces the upfront investment burden for purchasers and increases sales.

3.3 Marketing “Brick Block Machine for Sale” to B2B Clients

Effective marketing of “brick block machine for sale” inventory requires targeting the right B2B clients with tailored messaging:

- Distributor-to-Wholesaler Marketing: Highlight maker credibility, product quality, and profit margins. Use trade shows (e.g., Bauma, Conexpo) and B2B platforms (e.g., Alibaba, Made-in-China) to showcase machine demos and share client testimonials.

- Wholesaler-to-Purchaser Marketing: Emphasize machine performance, ROI, and after-sales support. Create case studies showing how similar purchasers increased production efficiency or reduced costs with your “for sale” machines.

- Digital Marketing: Use LinkedIn ads, industry websites (e.g., Construction Equipment Guide), and email campaigns to target brick manufacturers, construction companies, and government agencies. Create video content demonstrating machine operation, production speed, and brick quality.

- Technical Content: Publish whitepapers, blog posts, and webinars on topics like “How to Choose the Right Brick Block Machine for Your Production Needs” or “Maximizing ROI with Automatic Brick Block Machines.” This positions you as an industry expert and drives leads for your “for sale” inventory.

- Localization: Adapt marketing materials to regional languages and preferences. For example, in Africa, emphasize diesel power and durability; in Europe, highlight energy efficiency and environmental compliance.

4. Production Line Integration and Value-Added Services

4.1 Building Complete Production Lines for “For Sale”

To differentiate your “brick block machine for sale” offerings, partner with makers to integrate machines into complete production lines. A typical industrial-scale line includes:

- Raw Material Handling: Batching systems (automatic weighing and mixing), conveyors, and storage silos.

- Core Machine: Automatic brick block making machine (hydraulic or servo-electric).

- Curing System: Steam curing chambers, hot air tunnels, or natural curing racks.

- Finishing and Packaging: Robotic stackers, palletizers, stretch wrappers, and labeling systems.

- Control System: Central PLC panel with IoT connectivity for remote monitoring and data analytics.

Complete lines offer several advantages for “for sale” clients:

- Turnkey Solution: Purchasers can start production immediately without sourcing additional equipment.

- Optimized Efficiency: Integrated lines reduce material waste and production downtime compared to standalone machines.

- Higher Profit Margins: Complete lines have higher price points (up to 50% more than standalone machines) and generate more revenue for distributors and wholesalers.

4.2 Value-Added Services to Enhance “For Sale” Offerings

Offering value-added services alongside “brick block machine for sale” inventory increases customer loyalty and differentiates you from competitors:

- Installation and Commissioning: Provide on-site installation and commissioning services to ensure the machine or production line operates correctly. Charge a fee (5-10% of the machine price) for this service.

- Operator Training: Offer customized training programs for purchasers’ staff, covering machine operation, maintenance, and troubleshooting. Training can be delivered on-site or virtually.

- Maintenance Contracts: Sell annual or bi-annual maintenance contracts (10-15% of the machine price per year) that include routine servicing, spare parts replacement, and technical support. This generates recurring revenue and ensures long-term customer satisfaction.

- Custom Mold Design: Partner with mold manufacturers to offer custom mold design services for purchasers needing unique brick/block sizes or shapes. Charge a premium for custom molds (200-300% markup).

- Technical Consulting: Provide consulting services to help purchasers optimize their production processes, reduce costs, and comply with local regulations. This positions you as a trusted advisor and drives repeat business.

4.3 Troubleshooting Common Production Line Issues

As a B2B stakeholder selling complete production lines, you should be prepared to help purchasers troubleshoot common issues:

- Inconsistent Brick Quality: Caused by incorrect raw material mixing, uneven compaction, or mold wear. Solution: Adjust batching recipes, calibrate compaction pressure, or replace molds.

- Production Downtime: Caused by component failures, power outages, or operator error. Solution: Provide fast spare parts delivery, offer dual-power machines, or enhance operator training.

- High Energy Consumption: Caused by outdated motors or inefficient curing systems. Solution: Recommend energy-efficient upgrades (e.g., IE4 motors, solar-powered curing) or optimize production schedules.

- Environmental Compliance Issues: Caused by emissions from diesel machines or waste from raw material processing. Solution: Offer low-emission machines, waste recycling systems, or carbon footprint reduction consulting.

5. Global Market Dynamics and Regional Opportunities

5.1 Key Drivers of “Brick Block Machine for Sale” Demand

The global market for brick block machines is growing at a CAGR of 7-9%, driven by several key factors:

- Urbanization: Rapid urbanization in emerging economies (e.g., India, China, Nigeria) is fueling demand for affordable housing and infrastructure, increasing the need for high-capacity brick block machines.

- Phát triển cơ sở hạ tầng: Governments worldwide are investing in roads, bridges, airports, and public transportation projects, creating sustained demand for “for sale” machines that produce high-strength blocks.

- Sustainable Construction: Increasing environmental regulations are driving demand for machines that use recycled materials (e.g., fly ash, construction waste) or reduce energy consumption. Makers offering eco-friendly machines are gaining market share.

- Labor Shortages: Many regions (e.g., Europe, North America, Australia) face labor shortages in the construction sector, making automatic brick block machines (which reduce labor requirements) highly attractive to purchasers.

- Technological Advancements: Innovations like IoT monitoring, servo-electric compaction, and robotic stacking are improving machine efficiency and reliability, driving demand for modern “for sale” models.

5.2 Regional Market Opportunities for “For Sale” Machines

Different regions offer unique opportunities for “brick block machine for sale” stakeholders, based on local demand drivers and infrastructure:

5.2.1 Asia-Pacific

- Demand Drivers: Urbanization (India, China), infrastructure development (Vietnam, Indonesia), and affordable housing programs.

- Key “For Sale” Opportunities: Mid-range semi-automatic machines (2,000-10,000 bricks/day) and high-capacity automatic lines. Dual-power machines are popular in regions with unstable electricity.

- Maker Partnerships: Collaborate with Tier 2 and Tier 1 makers in China and India for cost-effective, regionally adapted machines.

5.2.2 Africa

- Demand Drivers: Rural development, population growth, and government housing initiatives.

- Key “For Sale” Opportunities: Budget-friendly manual and semi-automatic machines (500-5,000 bricks/day) with diesel power. Mobile machines are ideal for remote construction projects.

- Maker Partnerships: Partner with Tier 3 and Tier 2 makers offering durable, low-cost machines with local spare parts availability.

5.2.3 Middle East and North Africa (MENA)

- Demand Drivers: Luxury construction (UAE, Saudi Arabia), infrastructure projects (Qatar, Egypt), and heat-resistant block production.

- Key “For Sale” Opportunities: High-capacity automatic machines (10,000+ bricks/day) and decorative block machines. Energy-efficient models are preferred to comply with sustainability regulations.

- Maker Partnerships: Align with Tier 1 makers offering premium, customized machines for high-end projects.

5.2.4 Europe and North America

- Demand Drivers: Sustainable construction, heritage building restoration, and labor shortages.

- Key “For Sale” Opportunities: Energy-efficient automatic machines with IoT integration and recycled material processing capabilities. Small-scale automatic machines for boutique brick manufacturers are also in demand.

- Maker Partnerships: Collaborate with Tier 1 makers emphasizing environmental compliance and smart technology.

5.2.5 Latin America and the Caribbean

- Demand Drivers: Rural infrastructure development, affordable housing, and disaster relief.

- Key “For Sale” Opportunities: Mobile semi-automatic machines and mid-range automatic models. Dual-power machines are popular in regions with inconsistent electricity.

- Maker Partnerships: Partner with Tier 2 makers offering regionally adapted machines and fast delivery.

6. Conclusion

The intersection of “brick block machine maker” and “brick block machine for sale” presents a wealth of opportunities for B2B stakeholders—distributors, wholesalers, and purchasers alike. Success in this market requires two core actions: vetting reputable makers that prioritize quality, innovation, and support, and strategically positioning “for sale” products to meet regional demand and client needs. By aligning with the right makers (Tier 1 for premium markets, Tier 2 for emerging economies, Tier 3 for budget-focused regions), B2B stakeholders can build competitive “for sale” portfolios that drive profitability and customer loyalty. Additionally, offering value-added services (installation, training, maintenance contracts) and integrating machines into complete production lines differentiates your offerings from competitors and enhances long-term relationships with purchasers. As global urbanization, infrastructure development, and sustainable construction trends continue to drive demand, the “brick block machine for sale” market will remain a high-growth sector for B2B stakeholders willing to adapt to regional dynamics, prioritize quality, and foster collaborative partnerships with trusted makers. By leveraging the insights in this guide, you can navigate the complex landscape of brick block machine makers and “for sale” inventory to build a sustainable, profitable business in the global construction equipment industry.

7. FAQ (Frequently Asked Questions)

7.1 How do I verify the credibility of a brick block machine maker?

To verify a maker’s credibility:

- Request access to production facilities (in-person or virtual tour) to inspect manufacturing processes and quality control measures.

- Ask for client references and contact them to inquire about machine performance and after-sales support.

- Obtain sample machines and test their production capacity, brick quality, and durability.

- Check for certifications (ISO 9001, CE, ASTM) that demonstrate compliance with international standards.

- Review the maker’s warranty and after-sales support policies to ensure they are comprehensive.

7.2 What is the average lead time for “brick block machine for sale” orders?

Lead times vary by maker and machine type:

- Manual machines: 2-4 weeks (standard models).

- Semi-automatic machines: 4-6 weeks (standard models), 6-8 weeks (custom configurations).

- Automatic machines: 6-8 weeks (standard models), 8-12 weeks (custom production lines).

- Complete production lines: 12-16 weeks (integration of multiple components).Always confirm lead times in writing with the maker to avoid delays.

7.3 Can I customize “for sale” machines to meet regional brick size standards?

Yes. Reputable makers offer interchangeable molds and custom mold design services to match regional brick size standards (e.g., US standard: 203×92×57mm; European standard: 240×115×71mm; Indian standard: 230×115×75mm). Most makers can create custom molds within 2-4 weeks for an additional fee.

7.4 What is the typical ROI for purchasers of automatic brick block machines?

ROI for automatic machines depends on production capacity, brick selling price, and operational costs. A mid-range automatic machine ($30,000) producing 15,000 bricks/day (8-hour shift) typically has a payback period of 6-12 months. Key factors affecting ROI:

- Brick selling price ($0.10-$0.50 per brick, depending on region and type).

- Raw material costs (30-40% of selling price).

- Labor costs (3-5 operators per shift, vs. 10-20 for semi-automatic lines).

- Energy costs (15-30 kW/hour for automatic machines).

7.5 What spare parts should I stock for “for sale” machines to support purchasers?

Essential spare parts to stock include:

- Molds (wear-resistant steel or aluminum).

- Hydraulic hoses and seals (for hydraulic machines).

- Mixing blades and paddles.

- Compaction plates and bearings.

- Electrical components (motors, sensors, PLC modules).

- Lubricants and cleaning supplies.Stock 5-10% of total machine sales in spare parts to ensure fast delivery.

7.6 Are “for sale” brick block machines compatible with recycled materials?

Yes. Most modern machines (semi-automatic and automatic) can process recycled materials such as fly ash, construction waste, coal gangue, and recycled concrete. Makers can adjust machine settings (e.g., compaction pressure, mixing time) to optimize performance with recycled materials. This is a key selling point for eco-conscious purchasers.

7.7 How do I handle shipping and logistics for “for sale” machines to international markets?

To handle international shipping:

- Partner with freight forwarders specializing in heavy machinery to negotiate competitive rates.

- Use container shipping for large machines (20ft or 40ft containers) to reduce damage risk.

- Ensure machines are properly packaged (wooden crates, foam padding) to withstand transportation.

- Familiarize yourself with import regulations (customs duties, certifications) in target markets to avoid delays.

- Consider establishing local warehouses in key regions to reduce shipping costs and delivery times.

7.8 What after-sales services are most valuable to purchasers of “for sale” machines?

Purchasers prioritize the following after-sales services:

- 24/7 technical support for troubleshooting urgent issues.

- Fast spare parts delivery (2-5 days for critical parts).

- On-site installation and commissioning to ensure proper setup.

- Operator training to maximize machine efficiency and minimize errors.

- Extended warranty options (1-2 years beyond the standard warranty) for peace of mind.Offering these services increases customer satisfaction and drives repeat business for your “for sale” inventory.