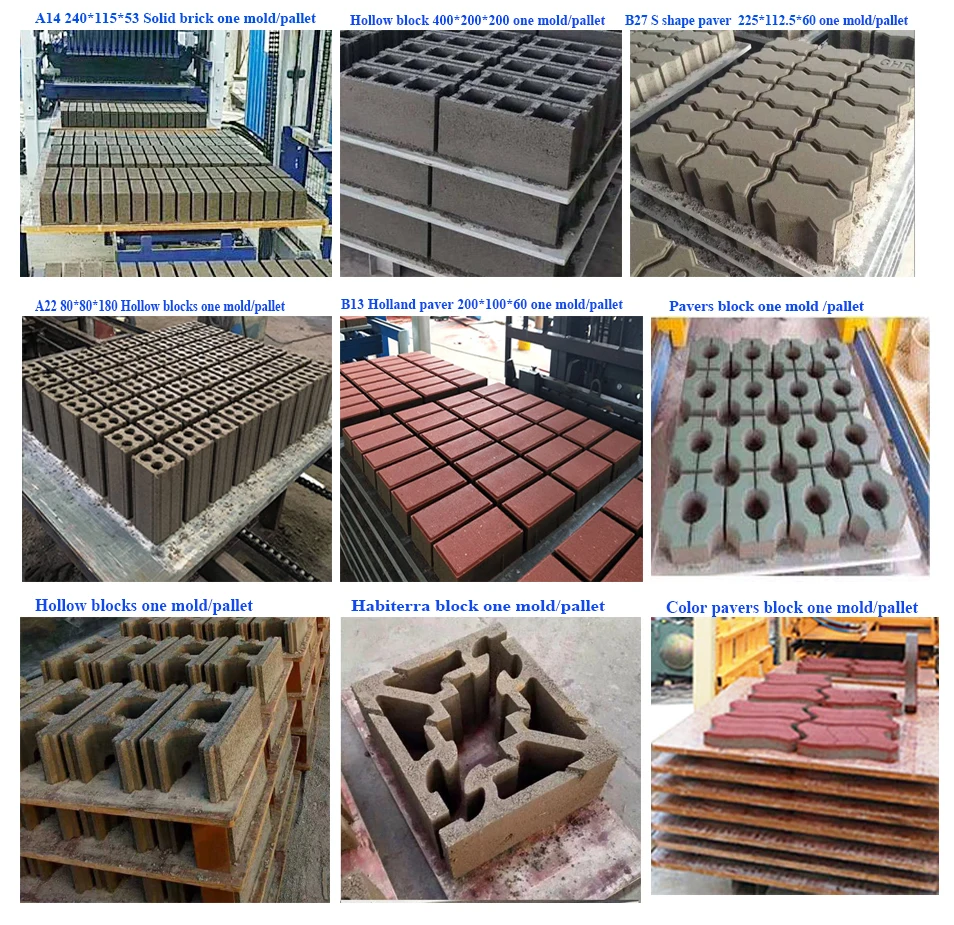

a. Entrega de materia prima con cargador de ruedas a la mezcladora, requiere 1 trabajador

b. Descarga de cemento en la mezcladora, desde el silo de cemento mediante un transportador de tornillo para cemento

c. Mezcladora mezclando material, luego entrega a la máquina de ladrillos, la cinta transportadora aquí necesita 1 trabajador

d. Después de hacer bloques, entregar los bloques a un apilador

e. El montacargas entrega bloques al área de curado, necesita 1 trabajador

f. Área de curado: El curado requiere de 10 a 15 días, luego se retiran los bloques del palet; se necesitan de 1 a 2 trabajadores.

g. Después del curado, sacar los bloques del palet, entregar el palet a la máquina alimentadora de palets con montacargas.

Bloques colocados en el área de almacenamiento de bloques

|

A

|

Máquina anfitriona de ladrillos QT12-15

a. Sistema automático de paletización b. Sistema automático de alimentación de materiales |

(2) Información técnica de la planta automática de ladrillos QT12-15:

|

||

|

B

|

Bloquear receptor

|

QT12-15 Potencia total de la máquina anfitriona

|

56 kilovatios

|

|

|

C

|

Stacker, podría apilar bloques de paletas de 4 a 5 capas.

|

Ciclo de moldeo

|

15 s

|

|

|

D

|

Cinta transportadora de 8 metros

|

Tamaño de la máquina de ladrillos anfitriona

|

5300*2050*2700

|

|

|

E

|

Mezcladora JS750 con mayor potencia, 38,6 KW

|

Peso

|

8000 KGS

|

|

|

F

|

Máquina de dosificación PLD 800, potencia, 9 KW

|

Tamaño del palé

|

1300*870 mm

|

|