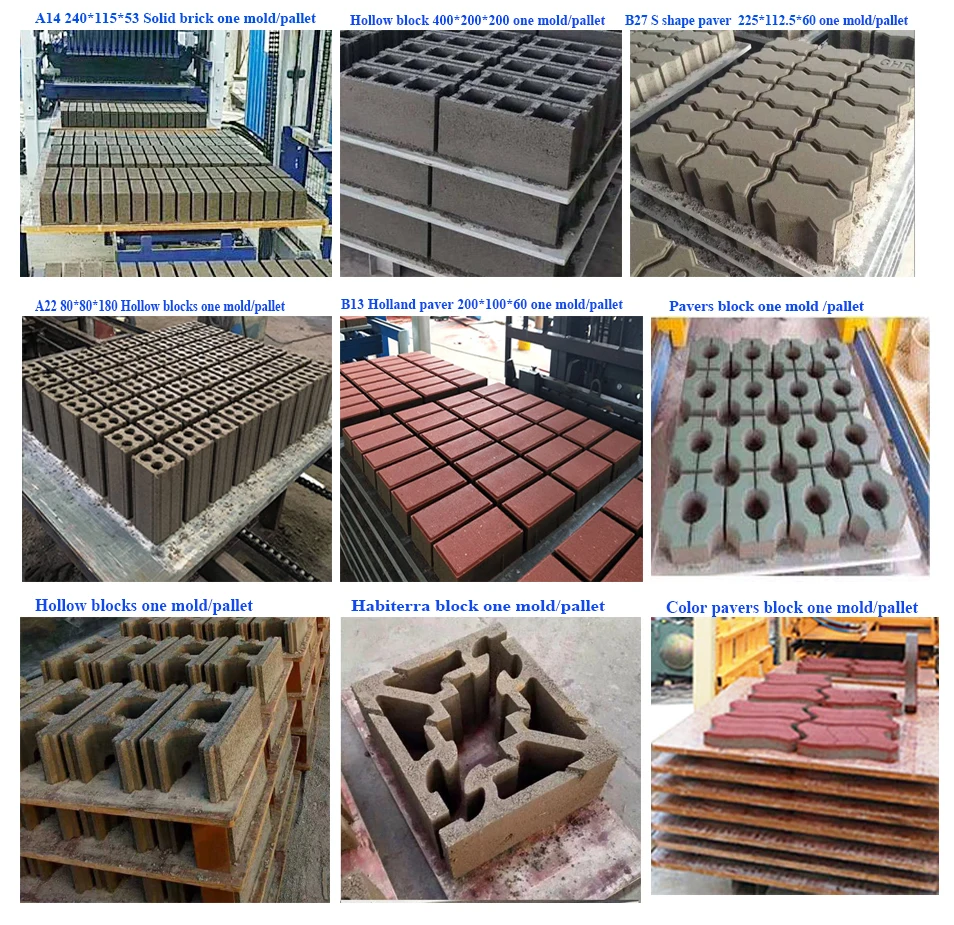

a. Grondstofgebruik: een wiellader levert de grondstoffen aan in de doseermachine, hiervoor is 1 werknemer nodig.

b. Cementlevering in de menger, vanuit de cementsilo via de cementschroeftransporteur

c. Menger die materiaal mengt, en vervolgens naar de steenmachine brengt, hier is 1 arbeider nodig voor de transportband

d. Na het maken van blokken, lever de blokken af bij een stapelaar

e. Heftruck levert blokken af bij de uithardingsruimte, heeft 1 werknemer nodig

f. Uithardingsgebied: Uitharding vereist 10-15 dagen, vervolgens blokken uit pallet halen; vereist 1-2 werknemers

g. Na het uitharden, haal de blokken uit de pallet, breng de pallet met een vorkheftruck naar de pallettoevoermachine.

Blokken liggen in het blokstapelgebied

|

A

|

QT12-15 Host brick machine

a. Automatisch palletsysteem b. Automatisch materiaalvoedsysteem |

(2)QT12-15 Automatic brick plant technical information:

|

||

|

B

|

Block receiver

|

QT12-15 Host machine total power

|

56 KW

|

|

|

C

|

Stacker, it could layer 4-5 pallets blocks

|

Molding cycle

|

15 s

|

|

|

D

|

8m conveyor

|

Host brick machine size

|

5300*2050*2700

|

|

|

E

|

JS750 Mixer bigger power, 38.6 KW

|

Weight

|

8000 KGS

|

|

|

F

|

Batching machine PLD 800, power, 9 KW

|

Pallet size

|

1300*870 mm

|

|