A Mecânica Operacional e os Componentes Principais

Princípios Fundamentais de Funcionamento

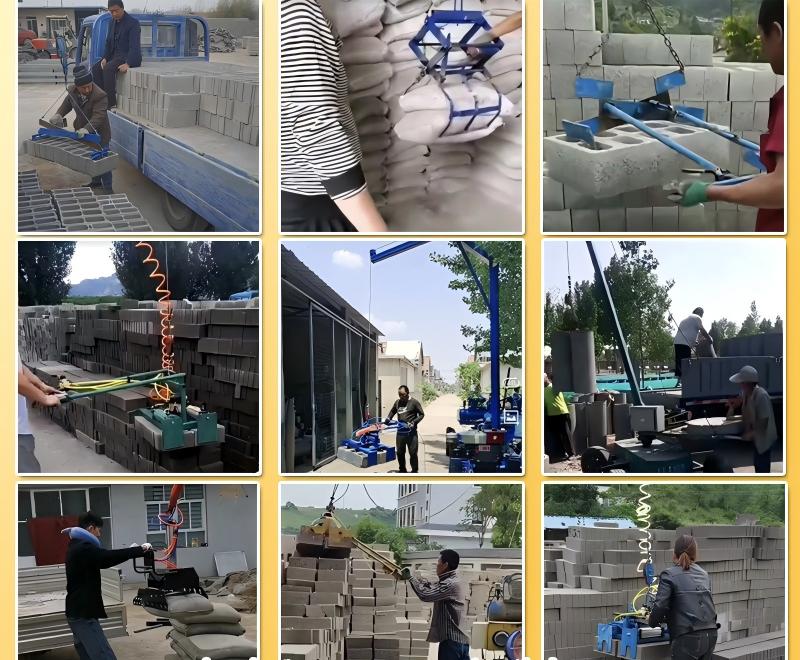

Em sua essência, essa máquina automatiza a coleta, o transporte e a colocação precisa de blocos de construção padronizados. O processo começa com a máquina se alinhando com uma carga paletizada, frequentemente usando sistemas de laser guiado ou guias físicos. Utilizando seu mecanismo de fixação proprietário, ela segura firmemente toda a pilha. A carga é então elevada, geralmente por meio de um robusto elevador tesoura ou sistema de braço hidráulico, e estabilizada para transporte. A máquina então se desloca — seja dirigida manualmente por um operador ou por meio de instruções pré-programadas em modelos mais avançados — até a área de descarga designada. Aqui, a colocação é executada com precisão milimétrica, garantindo que cada unidade seja posicionada corretamente para a subsequente assentamento de tijolos ou montagem. O ciclo se completa com a máquina retornando ao seu ponto de partida, pronta para a próxima carga. Essa operação repetitiva e de alta precisão elimina a variabilidade e a fadiga associadas ao manuseio manual.

Subsistemas Críticos e Suas Funções

A confiabilidade e o desempenho deste equipamento dependem de vários subsistemas integrados:

- Chassi e Estrutura de Mobilidade:Isso forma a espinha dorsal da máquina, projetada para estabilidade sob carga total. As opções incluem versões com esteiras para tração superior em terrenos acidentados e não preparados, e modelos com rodas para mobilidade mais suave em superfícies duras. A escolha do chassi impacta diretamente a aplicabilidade da máquina em diferentes condições de canteiro de obras.

- Mecanismo de Elevação e Manipulação:Este é o cerne da funcionalidade da máquina. Os sistemas variam de garfos simples no estilo de empilhadeira a cabeças sofisticadas com múltiplas garras, capazes de manusear diversos tamanhos e formatos de blocos. A força de elevação é fornecida por sistemas hidráulicos, conhecidos por sua alta densidade de força e controle suave, ou por atuadores eletromecânicos em modelos mais recentes que buscam maior eficiência energética.

- Interface de Controle e Orientação: The operator’s interface ranges from physical levers and joysticks in basic models to fully digital touchscreen panels. Advanced systems incorporate software that allows for the programming of repeated placement patterns, storing of common job parameters, and diagnostic feedback. Some high-end units feature semi-autonomous guidance, following pre-set paths or wire guides.

- Power and Propulsion System: Diesel engines offer traditional high power and longevity for all-day operation in remote sites. Electric motor-driven models, powered by large battery banks, are gaining popularity for indoor use, zero local emissions, and lower operational noise, aligning with green building initiatives.

- Safety and Stabilization Apparatus: Integral components include outriggers or stabilizer legs that deploy to prevent tipping during lifting operations. Sensors continuously monitor load weight, hydraulic pressure, and machine balance. Automatic shut-off features engage if parameters exceed safe limits, protecting both the machine and personnel.

Market Segmentation and Equipment Varieties

Classification by Mobility and Scale

The market offers differentiated products tailored to specific operational scales and environments.

- Compact and Mid-Range Units: These are highly maneuverable machines ideal for residential projects, smaller commercial builds, and retrofitting jobs. They are often trailer-mounted for easy transport between sites. Their focus is on agility and speed for frequent, smaller loads.

- High-Capacity Industrial Systems: Designed for large-scale industrial, commercial, and infrastructure projects, these units feature greater load capacity, extended reach, and often more sophisticated controls. They are built for durability and continuous operation, handling the vast material requirements of major construction sites.

- Specialized Attachment-Based Solutions: This category consists of modular attachments that can be fitted to existing carrier vehicles like telehandlers or mini-excavators. This offers a cost-effective entry point for contractors who already own compatible base machines, providing functional versatility.

Advanced Features and Technological Integration

Modern iterations are increasingly defined by their technological enhancements. Telematics systems allow fleet managers and dealers to monitor machine location, fuel levels, operational hours, and maintenance alerts remotely. This data is invaluable for preventive maintenance scheduling and optimizing machine utilization. Furthermore, integration with Building Information Modeling (BIM) represents the cutting edge. Machine controls can theoretically import data from a project’s BIM model, automating the placement pattern directly from the digital blueprint, thereby reducing layout errors and further accelerating the construction process.

Strategic Advantages for the Supply Chain and End-Users

Quantifiable Economic and Operational Benefits

The adoption of this machinery delivers a compelling return on investment through multiple channels. The most direct impact is the dramatic reduction in labor costs; a single machine and operator can replace a crew of several manual laborers, completing tasks in a fraction of the time. This translates directly to shorter project timelines, allowing contractors to take on more projects per year. Material waste due to handling damage is minimized, as the consistent, mechanical movement prevents chipping and breakage common in manual throws and carries. Furthermore, the precision placement reduces the need for subsequent adjustments, allowing masons or assemblers to begin their work immediately and more efficiently.

Enhancing Safety and Ergonomic Standards

Beyond economics, the safety imperative is profound. Manual handling of heavy, dense building materials is a leading cause of musculoskeletal injuries, including chronic back problems and strains. By assuming this physically demanding task, the machinery drastically lowers the incidence of such injuries. It also reduces foot traffic and congestion in the primary material drop zones, minimizing the risk of struck-by incidents. This creates a safer, more organized worksite, which can lead to lower insurance premiums and improved regulatory compliance for the end-user.

Sustainability and Industry Alignment

The efficiency gains have a direct positive environmental impact. Faster project completion reduces the overall duration of site disturbance and energy consumption on-site. Electric models, in particular, contribute to quieter, emission-free operation, which is crucial for urban projects with strict noise and pollution ordinances. By promoting a solution that aligns with goals for faster, safer, and cleaner construction, distributors align themselves with the broader trends shaping the future of the industry.

Conclusion: Positioning for a Productive Future

The transition towards automated material handling in construction is not a speculative trend but a demonstrable shift towards greater rationality and productivity. For dealers, distributors, and procurement professionals, this equipment category represents a high-value portfolio segment that addresses fundamental client pain points: cost, time, safety, and precision. Success in this market requires a deep technical understanding of the product variations, a clear communication of the total cost of ownership and ROI, and the ability to provide robust after-sales support and parts service. By becoming knowledgeable advocates for these solutions, supply chain partners do more than sell machinery; they enable their clients to build better, faster, and safer. The competitive advantage offered by this technology makes it an indispensable consideration for any forward-looking business servicing the modern construction landscape.

Frequently Asked Questions (FAQ)

Q1: What is the typical range of load capacity for these machines?

A: Load capacities vary significantly to suit different projects. Compact models may handle stacks weighing between 500 to 1,500 kg, while heavy-duty industrial machines can lift and transport palletized loads exceeding 3,000 kg. It is crucial to match the machine’s capacity with the most common pallet weights used by your clientele.

Q2: How does the training process work for operators, and is it complex?

A: Operator training is generally straightforward, especially for standard models. Most manufacturers provide comprehensive onsite training covering basic operations, safety protocols, and routine maintenance. For machines with advanced software or BIM integration, more in-depth training is provided. The intuitive nature of the controls allows skilled equipment operators to become proficient relatively quickly.

Q3: What are the primary considerations for choosing between a tracked and wheeled model?

A: The choice depends on anticipated ground conditions. Tracked models offer superior ground pressure distribution, making them ideal for soft, muddy, or uneven terrain as they are less likely to sink or cause damage. Wheeled models provide higher travel speeds and are better suited for hard, level surfaces like prepared pads or factory floors. They also tend to be easier to transport on trailers.

Q4: Can these machines handle other materials besides standard construction blocks?

A: Yes, with the appropriate attachments, many models can be adapted to handle a variety of palletized or bundled materials common on construction sites. This includes bags of mortar mix, landscaping blocks, certain types of paving stones, and dimensional lumber packs. This versatility enhances the machine’s utility and ROI for the end-user.

Q5: What does the maintenance schedule look like, and what is the parts availability like?

A: Maintenance is similar to other mobile construction equipment, involving regular checks of hydraulic systems, filters, structural components, and (in diesel models) the engine. Electric models have fewer moving parts and require less routine maintenance. Reputable manufacturers support their products with readily available spare parts networks and detailed service manuals. For distributors, establishing access to this parts supply chain is a critical component of customer support.

Q6: How do we effectively demonstrate the ROI to a skeptical contractor?

A: The most effective demonstration is a concrete cost-benefit analysis. Focus on direct labor savings: calculate the hours and crew size required to manually move a set quantity of material versus the machine’s cycle time. Add in quantifiable savings from reduced breakage, lower insurance costs (due to improved safety), and the potential for increased project throughput. Offering a live demonstration on the contractor’s own site, using their materials, is often the most persuasive tool.