1. Hordhac

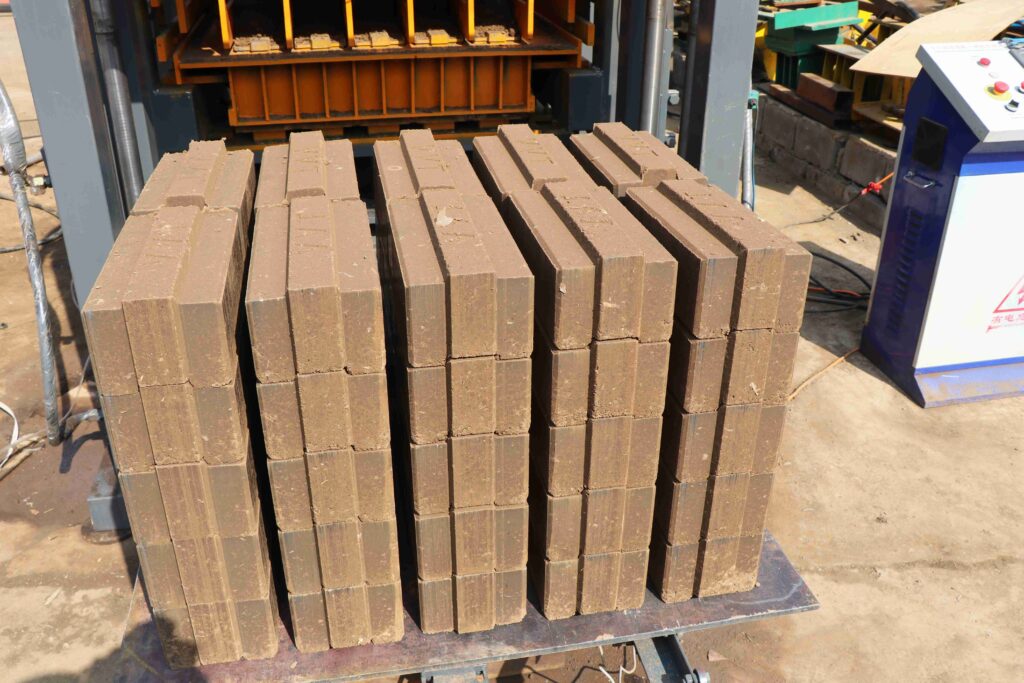

Makiinada sameynta libooyka dhoobo ah ayaa u taagan shaqaalaha waqtiga dhan ee warshada qalabka dhismaha adduunka, iyadoo la isticmaalayo mid ka mid ah qalabka dhismaha ugu da'da weyn iyo ugu badan - dhoobo - si loo soo saaro libooyka adag, kala duwan, iyo qiimo jaban. Loo yaqaano iibiyeyaasha, iibka jumlada, iyo iibsadayaasha ka shaqeeya meelaha B2B, makiinadan waxay u taagan qaybo alaab ah oo deggan oo dalbo sare leh, oo ay horseeday helitaanka caalamiga ah ee dhoobada, ku habboonaanta deegaanka, iyo muhiimada joogtada ah ee mashruucyada guryaha, ganacsiga, iyo maamulka.

2. Aasaasiyada Gaarka ah ee Dhagaxa: Sababta Aaladaha Sameynta Dhagaxa Dhagaxa ay Muhiimsan yihiin

2.1 Astaamaha Gaarka ah ee Dhoobada ee La Isticmaalo Qalabka

Khalqaydaha dabiiciga ah ee dhagaxa waxay ka dhigayaan mid ku habboon wax soo saarka lebbiska, iyo makiinadaha sameynta lebbiska dhagaxa waxaa loo habeeyey si loo isticmaalo sifooyinkan si loo gaaro natiijooyinka ugu fiican. Fahamka dhaqanka dhagaxa waa muhiim u ah shaqsiyaadka B2B si ay ugu taliso macaamiisha, ay u doortaan makiinado ku habboon, oo ay xalliyaan dhibaatooyinka soo saarka:

- DhismeedDhoobku wuxuu noqdaa mid la qasban karo marka la isku daro biyo, taasoo u oggolaanaysa in la sameeyo lebis cufan oo aan jebin. Makiinadaha samaynta lebbiska dhoobka waxay ku faa'iidaystaan qasabkaas iyagoo adeegsanaya qaab-dhismeed iyo cufnaan sax ah, taasoo hubinaysa cabbirka lebbiska iyo dhismaha isku midka ah.

- Isku-dheellitir: Clay particles bind tightly together when compacted and dried, creating bricks with natural strength and durability. High-quality clay bricks can withstand compressive strengths of 10-25 N/mm², meeting global construction standards for load-bearing walls.

- Thermal Mass: Clay bricks retain heat, improving the energy efficiency of buildings by regulating indoor temperatures. This eco-friendly feature is increasingly valued in sustainable construction, driving demand for clay brick making machines in green building markets.

- Abundance and Affordability: Clay is a naturally occurring resource found in nearly every region of the world, reducing raw material transportation costs for brick manufacturers. Unlike concrete (which requires cement, a high-cost commodity), clay is low-cost and readily accessible, making clay brick production economically viable for small to large-scale operations.

- Biodegradability and Recyclability: Clay bricks are non-toxic, biodegradable, and can be recycled into aggregate for road construction or new brick production. This aligns with global environmental regulations, making clay brick making machines a compliant choice for clients seeking eco-friendly production solutions.

2.2 Types of Clay Brick Making Machines: Tailored to Production Needs

Clay brick making machines are categorized based on their production process, output capacity, and level of automation—each designed to meet specific client requirements and regional conditions. Distributors and wholesalers should familiarize themselves with these types to match clients with the right equipment:

2.2.1 Manual Clay Brick Making Machines

- Overview: Compact, hand-operated machines ideal for small-scale producers, rural entrepreneurs, or regions with limited electricity. These machines require manual feeding of clay, compaction via hand levers, and manual demolding.

- Key Features: Low cost ($1,000-$5,000), lightweight (200-500 kg), no power requirements, and simple operation. Molds are interchangeable, supporting standard brick sizes (e.g., 240×115×57mm) and small custom sizes.

- Qaybinta Soo saarista: 500-2,000 bricks per day (8-hour shift), suitable for local rural construction, small housing projects, or artisanal brick production.

- Target Clients: Individual entrepreneurs, village-level brick yards, and purchasers in remote areas with no access to electricity or capital for larger machines.

2.2.2 Semi-Automatic Clay Brick Making Machines

- Overview: Hybrid machines combining manual feeding with automated compaction and molding. These machines bridge the gap between manual and automatic models, offering higher efficiency at a moderate cost.

- Key Features: Powered by electricity (3-10 kW) or diesel engines (5-15 HP), hydraulic or mechanical compaction, and semi-automatic demolding. Equipped with simple control panels for adjusting compaction pressure and mold settings.

- Qaybinta Soo saarista: 2,000-10,000 bricks per day, suitable for medium-scale brick yards serving regional construction markets.

- Target Clients: Small to medium-sized brick manufacturers, rural construction cooperatives, and purchasers with limited capital but growing production needs.

2.2.3 Automatic Clay Brick Making Machines (Extrusion-Based)

- Overview: Industrial-scale machines using extrusion technology to produce high-volume clay bricks. These machines automate the entire process: clay mixing, extrusion, cutting, drying, and (in some cases) firing.

- Key Features: High-power motors (15-30 kW), screw extruders for clay shaping, wire cutters for precise brick dimensions, and integration with drying racks or kilns. Advanced models feature PLC control systems for real-time production monitoring.

- Qaybinta Soo saarista: 10,000-50,000+ bricks per day, suitable for large-scale brick manufacturers supplying urban construction, municipal projects, or export markets.

- Target Clients: Large brick production facilities, national construction contractors, and purchasers operating in high-demand markets (e.g., India, China, Southeast Asia).

2.2.4 Mobile Clay Brick Making Machines

- Overview: Portable machines designed to be transported to clay deposits or construction sites, eliminating the need for clay transportation. These machines are ideal for regions with scattered clay reserves or remote construction projects.

- Key Features: Mounted on trailers or skids, powered by diesel engines (10-20 HP), and equipped with on-board clay mixing and molding systems. Some models include mobile drying racks for on-site curing.

- Qaybinta Soo saarista: 1,000-5,000 bricks per day, suitable for rural road construction, temporary housing projects, or brick production in areas with no fixed brick yards.

- Target Clients: Construction companies, government agencies (for infrastructure projects), and distributors serving remote or disaster-stricken regions.

2.2.5 Traditional vs. Modern Clay Brick Making Machines

Traditional clay brick making (manual molding and sun-drying or kiln-firing) is labor-intensive and produces inconsistent quality. Modern clay brick making machines address these issues by:

- Ensuring uniform brick dimensions and density through automated compaction.

- Reducing drying/firing time with integrated curing systems.

- Minimizing clay waste (traditional methods waste 15-20% of clay; modern machines waste <5%).

- Lowering labor requirements (1 operator for semi-automatic machines vs. 5-10 workers for manual methods).

2.3 Critical Components of Clay Brick Making Machines

Clay brick making machines feature specialized components tailored to handle clay’s unique properties (plasticity, moisture sensitivity). Distributors and purchasers should evaluate these components to assess machine durability and performance:

- Clay Mixing Unit: Mixes raw clay with water to achieve optimal moisture content (15-25%, depending on clay type). Equipped with spiral blades or paddles for thorough blending, preventing lumps that can cause brick cracks.

- Molding System: Shapes clay into bricks using interchangeable molds. For clay, molds are typically made of wear-resistant steel or aluminum to withstand clay’s abrasive nature. Some molds include texture patterns for decorative bricks.

- Qaabka Isku-dhafka: Applies pressure (10-30 MPa) to clay in the mold, removing air bubbles and enhancing brick density. Hydraulic compaction is preferred for clay bricks, as it provides consistent pressure and reduces brick shrinkage during drying.

- Demolding System: Gently ejects compacted clay bricks from the mold to avoid damage. Manual machines use hand levers, while semi-automatic/automatic machines use hydraulic cylinders or conveyor belts.

- Drying/Curing Attachment: Optional component for accelerating clay brick drying. Can include fans, heaters, or solar-powered drying racks. Critical for regions with high humidity or short dry seasons.

- Frame and Chassis: Constructed from high-grade steel to withstand the vibration and pressure of clay compaction. Mobile machines have reinforced chassis for transportation over rough terrain.

3. Market Opportunities and Regional Demand Drivers

3.1 Global Market Trends for Clay Brick Making Machines

The global market for clay brick making machines is projected to grow at a CAGR of 6-8% over the next decade, driven by several key trends that create opportunities for B2B stakeholders:

- Urbanization in Emerging Economies: Countries like India, Pakistan, Bangladesh, and Nigeria are experiencing rapid urbanization, with millions of new homes and infrastructure projects requiring clay bricks. For example, India’s Pradhan Mantri Awas Yojana (Housing for All) initiative aims to build 20 million affordable homes by 2025, creating massive demand for clay brick making machines.

- Sustainable Construction Mandates: Governments worldwide are enforcing green building standards (e.g., LEED, BREEAM) that prioritize eco-friendly materials. Clay bricks’ thermal efficiency, recyclability, and low carbon footprint make them compliant with these standards, driving demand for clay brick making machines in developed and developing markets.

- Infrastructure Development: Road construction, bridge building, and public transportation projects (e.g., railways, airports) use clay bricks for retaining walls, pavement, and drainage systems. Governments in Southeast Asia (Vietnam, Indonesia) and Africa (Ethiopia, Kenya) are investing billions in infrastructure, boosting sales of high-capacity clay brick making machines.

- Artisanal and Decorative Brick Markets: The demand for decorative clay bricks (textured, colored, or custom-shaped) is growing in high-end residential and commercial construction. Clay brick making machines with custom mold options cater to this niche, offering distributors and purchasers higher profit margins.

3.2 Regional Market Analysis: Key Opportunities by Geography

Clay brick making machines have distinct regional demand drivers, and B2B stakeholders should tailor their offerings to local conditions:

3.2.1 Asia-Pacific

- Demand Drivers: Abundant clay reserves, rapid urbanization, and affordable labor. India and China are the largest markets, with high demand for automatic extrusion-based machines. Southeast Asia (Vietnam, Thailand) prefers semi-automatic and mobile machines for rural construction.

- Key Considerations: Clay types vary (e.g., red clay in India, kaolin in China), so machines must be compatible with local clay moisture content and particle size. Power infrastructure is improving, but dual-power (electric + diesel) machines are still preferred in remote areas.

3.2.2 Africa

- Demand Drivers: Growing population, rural-to-urban migration, and government housing initiatives. Clay is widely available across the continent, making clay brick making machines accessible to small-scale producers.

- Key Considerations: Limited power access in rural areas favors manual and diesel-powered semi-automatic machines. Affordability is critical—distributors should offer low-cost, durable models with local spare parts availability.

3.2.3 Middle East and North Africa (MENA)

- Demand Drivers: Infrastructure development (e.g., Saudi Arabia’s NEOM project, UAE’s Expo 2020 legacy projects) and demand for heat-resistant clay bricks (suitable for arid climates).

- Key Considerations: Clay bricks must withstand high temperatures (up to 50°C), so machines with high compaction pressure (25-30 MPa) are preferred. Decorative clay bricks are in demand for luxury residential and tourist projects.

3.2.4 Europe and North America

- Demand Drivers: Sustainable construction trends, heritage building restoration (clay bricks are used in historic buildings), and demand for high-performance thermal bricks.

- Key Considerations: Strict environmental regulations require machines to reduce energy consumption and emissions. Automatic machines with energy-efficient motors and recycled clay processing capabilities are favored. Custom mold options for heritage brick replication are a key selling point.

3.3 Competitive Advantages of Clay Brick Making Machines for B2B Stakeholders

For distributors, wholesalers, and purchasers, clay brick making machines offer unique competitive advantages compared to other brick production equipment (e.g., concrete brick machines):

- Lower Raw Material Costs: Clay is cheaper and more abundant than concrete (which requires cement, sand, and aggregate), reducing production costs for clients and increasing profit margins for distributors.

- Eco-Friendly Branding: Clay bricks are perceived as sustainable, allowing distributors to market machines to eco-conscious clients and access green building markets.

- Reduced Regulatory Barriers: Unlike concrete brick production (which may face restrictions on cement use due to carbon emissions), clay brick production is generally unregulated, simplifying sales in strict environmental markets.

- Long-Term Durability: Clay bricks have a lifespan of 100+ years, making them a preferred choice for permanent structures. This durability translates to repeat business for distributors (clients need replacement machines after decades, not years).

- Cultural and Aesthetic Appeal: Clay bricks have a natural, warm appearance that is valued in residential and commercial construction. Decorative clay bricks (e.g., terracotta, textured) command higher prices, offering purchasers higher revenue potential.

4. Technical Considerations for Sourcing and Investing

4.1 Evaluating Clay Compatibility: A Make-or-Break Factor

Clay composition varies by region (e.g., sandy clay, plastic clay, loamy clay), and not all clay brick making machines are compatible with all clay types. Distributors and purchasers must evaluate clay compatibility to avoid production issues:

- Moisture Content: Clay requires 15-25% moisture for optimal molding. Machines should have adjustable water mixing systems to accommodate clay with high or low natural moisture.

- Particle Size: Clay with fine particles (<0.075 mm) is more plastic and easier to mold. Machines with powerful mixing units can handle clay with larger particles (up to 2 mm) by breaking them down.

- Impurity Levels: Clay containing stones, organic matter, or salt can cause brick cracks or discoloration. Machines should have sieving components to remove impurities, or distributors should advise clients to pre-process clay (e.g., crushing, washing).

- Shrinkage Rate: Clay shrinks during drying and firing (5-10% for most clays). Machines with adjustable mold sizes can compensate for shrinkage, ensuring finished bricks meet standard dimensions.

4.2 Key Technical Specifications to Compare

When sourcing or investing in clay brick making machines, B2B stakeholders should prioritize the following technical specifications to ensure performance and value:

| Qeexitaan | Manual Machines | Semi-Automatic Machines | Automatic Machines |

|---|---|---|---|

| Output Capacity (Bricks/Day) | 500-2,000 | 2,000-10,000 | 10,000-50,000+ |

| Shuruudaha Korontada | None (Manual) | 3-10 kW / 5-15 HP (Diesel) | 15-30 kW |

| Compaction Pressure | 5-10 MPa (Manual) | 10-20 MPa (Hydraulic/Mechanical) | 20-30 MPa (Hydraulic) |

| Mold Compatibility | Standard Sizes (Interchangeable) | Standard + Custom Sizes | Standard + Custom Sizes (High Precision) |

| Clay Moisture Range | 18-25% | 15-22% | 12-20% (Adjustable Mixing) |

| Machine Weight | 200-500 kg | 1-5 tons | 10-30 tons |

| Installation Requirement | None (Portable) | Flat Concrete Surface | Dedicated Foundation + Production Line Space |

| Labor Requirement | 2-3 Operators | 1-2 Operators | 3-5 Operators (Full Line) |

4.3 Drying and Firing: Critical Post-Molding Processes

Clay bricks require drying and (in most cases) firing to achieve strength and durability. Distributors should educate purchasers on these processes and offer compatible equipment:

- Drying: Clay bricks must be dried slowly (7-14 days) to remove moisture without cracking. Options include:

- Natural Drying: Sun-drying on racks (low cost, suitable for dry climates).

- Artificial Drying: Drying chambers with fans and heaters (faster, suitable for humid climates or high-volume production).

- Firing: Firing at 900-1,200°C strengthens clay bricks and improves water resistance. Kiln options include:

- Traditional Kilns: Wood or coal-fired (low cost, high emissions).

- Modern Kilns: Gas or electric-fired (energy-efficient, low emissions, compliant with environmental regulations).

- Machine-Kiln Integration: High-end automatic clay brick making machines can be integrated with continuous kilns, creating a fully automated production line from clay mixing to fired bricks. This integration is a key selling point for large-scale purchasers.

4.4 Maintenance and Spare Parts: Ensuring Long-Term Performance

Clay brick making machines require regular maintenance to handle clay’s abrasive nature. Distributors should offer comprehensive maintenance support to retain clients:

- Routine Maintenance Tasks:

- Cleaning clay residue from mixing units, molds, and compaction mechanisms (daily).

- Lubricating moving parts (bearings, hydraulic cylinders) (weekly).

- Inspecting molds for wear and tear (monthly).

- Replacing sieves and filters (quarterly).

- Critical Spare Parts:

- Molds (wear-resistant steel or aluminum).

- Mixing blades (abrasion-resistant).

- Hydraulic hoses and seals (for hydraulic machines).

- Compaction plates (high-strength steel).

- Spare Parts Availability: Distributors should stock essential spare parts locally or partner with manufacturers to provide fast shipping (2-5 days for urgent parts). This minimizes production downtime for purchasers.

5. Business Strategy for Distributors and Wholesalers

5.1 Building a Profitable Product Portfolio

Distributors and wholesalers should curate a product portfolio of clay brick making machines to cater to diverse client segments:

- Entry-Level Offerings: Manual and small semi-automatic machines (low cost, high volume sales) for rural entrepreneurs and small brick yards.

- Mid-Range Offerings: Medium semi-automatic and mobile machines (moderate cost, higher margins) for regional brick manufacturers.

- High-End Offerings: Automatic extrusion machines and integrated production lines (high cost, high margins) for large-scale producers and export markets.

- Complementary Products: Offer drying racks, kilns, clay crushers, and sieves to increase average order value.

5.2 Marketing and Sales Tactics for B2B Success

- Targeted Lead Generation: Attend construction equipment trade shows (e.g., Bauma, Conexpo) and regional building materials expos to connect with purchasers. Use digital marketing (LinkedIn ads, industry websites) to target brick manufacturers and construction companies.

- Technical Demonstrations: Offer on-site or virtual demonstrations of clay brick making machines to showcase production speed, brick quality, and ease of operation. Provide sample bricks to clients for strength and durability testing.

- Customization Services: Highlight custom mold options for decorative or regional brick sizes. Partner with local mold manufacturers to offer fast customization.

- Financing and Leasing Options: For high-cost automatic machines, offer financing (low-interest loans) or leasing to reduce upfront investment for purchasers. Partner with financial institutions specializing in construction equipment.

- After-Sales Support Packages: Bundle machines with maintenance contracts, operator training, and spare parts discounts to differentiate from competitors. Offer 24/7 technical support via phone or video call.

5.3 Scaling into Global Markets

For distributors looking to expand internationally, consider these strategies:

- Regional Warehousing: Establish warehouses in key markets (e.g., India, Nigeria, Vietnam) to reduce shipping costs and delivery times.

- Localization: Adapt machines to regional voltage standards (e.g., 110V for North America, 220V for Europe/Asia) and clay types. Provide user manuals in local languages.

- Partner with Local Agents: Collaborate with local distributors or agents who understand regional market dynamics and can provide on-site support.

- Compliance with Import Regulations: Ensure machines meet regional safety and environmental standards (e.g., CE for Europe, ISO for global markets). Provide certification documents to avoid customs delays.

6. Conclusion

Clay brick making machines represent a resilient and profitable opportunity for distributors, wholesalers, and purchasers in the global construction equipment market. Driven by clay’s abundance, sustainability, and enduring demand in construction, these machines cater to diverse client segments—from small-scale rural entrepreneurs to large industrial producers. Success in this market requires a deep understanding of clay-specific technicalities, regional market dynamics, and client pain points (e.g., clay compatibility, moisture control, drying challenges). For B2B stakeholders, the key to growth lies in:

- Matching clients with machines tailored to their production scale, clay type, and regional conditions.

- Emphasizing the eco-friendly and cost-effective advantages of clay brick production.

- Providing comprehensive after-sales support, including maintenance, training, and spare parts.

- Scaling product portfolios and sales strategies to tap into high-growth markets (e.g., Asia, Africa, MENA).

As the construction industry continues to prioritize sustainability and affordability, clay brick making machines will remain a critical component of building material production. By leveraging the insights in this guide, distributors, wholesalers, and purchasers can capitalize on this demand, build long-term business relationships, and achieve sustainable growth in the competitive B2B landscape.

7. FAQ (Frequently Asked Questions)

7.1 What type of clay is best for brick making?

The ideal clay for brick making is plastic clay (also known as brick clay), which has high plasticity, low sand content (<20%), and moderate shrinkage (5-8%). Plastic clay binds well when compacted and dries without cracking. Clay with excessive sand (sandy clay) may require additional water or plasticizers, while clay with high organic matter (loamy clay) may need firing at higher temperatures to remove impurities.

7.2 Can clay brick making machines produce colored bricks?

Yes. Colored clay bricks are produced by adding natural pigments (e.g., iron oxide for red/brown, manganese oxide for black) to the clay mix. Most semi-automatic and automatic clay brick making machines support pigment mixing via the clay mixing unit. For decorative colored bricks, custom molds with texture patterns can be used.

7.3 How long does it take to produce a batch of clay bricks?

Production time varies by machine type and drying/firing method:

- Manual Machines: 15-20 seconds per brick (molding), plus 7-14 days drying, plus 24-48 hours firing (total: 8-16 days per batch).

- Semi-Automatic Machines: 10-15 seconds per brick (molding), plus 5-7 days drying, plus 12-24 hours firing (total: 6-8 days per batch).

- Automatic Machines: 5-10 seconds per brick (molding), plus 2-3 days artificial drying, plus 6-12 hours continuous firing (total: 3-4 days per batch).

7.4 Are clay brick making machines suitable for cold climates?

Yes, but adjustments are needed:

- Drying: Use heated drying chambers to prevent clay from freezing during drying.

- Firing: Insulate kilns to maintain temperature in cold weather.

- Machine Operation: Use low-temperature lubricants for moving parts to avoid freezing.Some manufacturers offer cold-climate-adapted machines with built-in heating systems for mixing units and molds.

7.5 What is the average lifespan of a clay brick making machine?

- Manual Machines: 5-8 years (with regular maintenance).

- Semi-Automatic Machines: 8-12 years (depending on component quality).

- Automatic Machines: 12-15 years (industrial-grade components and modular design).Lifespan can be extended by using high-quality clay (low impurity content), following maintenance schedules, and replacing wear parts promptly.

7.6 Do clay brick making machines require specialized training to operate?

- Manual Machines: No specialized training—operators can learn basic functions in 1-2 hours.

- Semi-Automatic Machines: 1-2 days of training (focus on control panel operation, clay mixing, and mold changes).

- Automatic Machines: 1-2 weeks of training (covers PLC systems, production line integration, and troubleshooting).Distributors should provide free training (on-site or online) to ensure safe and efficient operation.

7.7 Can clay brick making machines use recycled clay or construction waste?

Yes. Most modern machines can process recycled clay (e.g., broken bricks, clay scrap) or construction waste (e.g., clay-based demolition debris) as part of the raw material mix (up to 30%). This reduces waste and raw material costs for purchasers, aligning with sustainable construction trends.

7.8 What after-sales services should distributors prioritize for clay brick making machines?

Essential after-sales services include:

- 1-2 year warranty on machine components (excluding wear parts like molds).

- On-site or virtual operator training.

- 24/7 technical support for troubleshooting.

- Fast spare parts delivery (local stock or express shipping).

- Maintenance contracts (annual or bi-annual servicing).

- Kiln and drying system installation support (for integrated production lines).These services build trust with purchasers and encourage repeat business.