La columna vertebral de la industria de la construcción son sus materiales, y entre los más fundamentales están los ladrillos de cemento. El equipo utilizado para producir estos componentes ha evolucionado desde herramientas manuales simples hasta sistemas altamente sofisticados y automatizados.

Análisis Integral de las Máquinas para Fabricar Ladrillos de Cemento

1.1 Principio Operativo Central y Flujo de Trabajo

En esencia, una máquina para fabricar ladrillos de cemento automatiza el proceso de compactar una mezcla de cemento, áridos (como arena o piedra triturada) y agua en un molde para formar un ladrillo de dimensiones y densidad específicas. El flujo de trabajo fundamental puede desglosarse en varias etapas distintas.

- Dosificación y Mezcla de Materias Primas:El proceso comienza con la dosificación precisa de las materias primas. Esto se realiza frecuentemente mediante sistemas automatizados de dosificación o de forma manual, dependiendo del nivel de sofisticación de la máquina. Los componentes secos se mezclan a fondo antes de añadir agua para lograr una mezcla de hormigón homogénea y semiseca con la consistencia adecuada para la compactación.

- Llenado del Molde: The prepared mixture is then conveyed or fed into the machine’s mold cavity. The mold, or die, is a precision-engineered component that defines the brick’s shape, size, and surface texture. Advanced machines ensure uniform filling to guarantee consistent weight and density across all products.

- Compactación a Alta Presión: This is the most critical phase. A hydraulic or mechanical system applies immense pressure to the mixture within the mold. This compression force eliminates air voids, densely packs the particles together, and gives the brick its structural integrity and high strength. The pressure level, measured in tons or megaPascals, is a key determinant of the final product’s quality.

- Curing and Demolding: After compaction, the newly formed brick, known as a “green brick,” is ejected from the mold. In stationary plants, these green bricks are transported to a curing chamber. Curing involves maintaining controlled temperature and humidity for a set period, which allows the cement to fully hydrate and gain strength. Some mobile machines may produce bricks that are cured naturally by stacking and covering them.

- Brick Handling and Palletizing: Once cured and sufficiently hardened, the finished bricks are automatically or manually stacked onto pallets for storage, transportation, and distribution. Automated palletizing systems significantly reduce labor requirements and handling damage.

1.2 Classification and Types of Machines

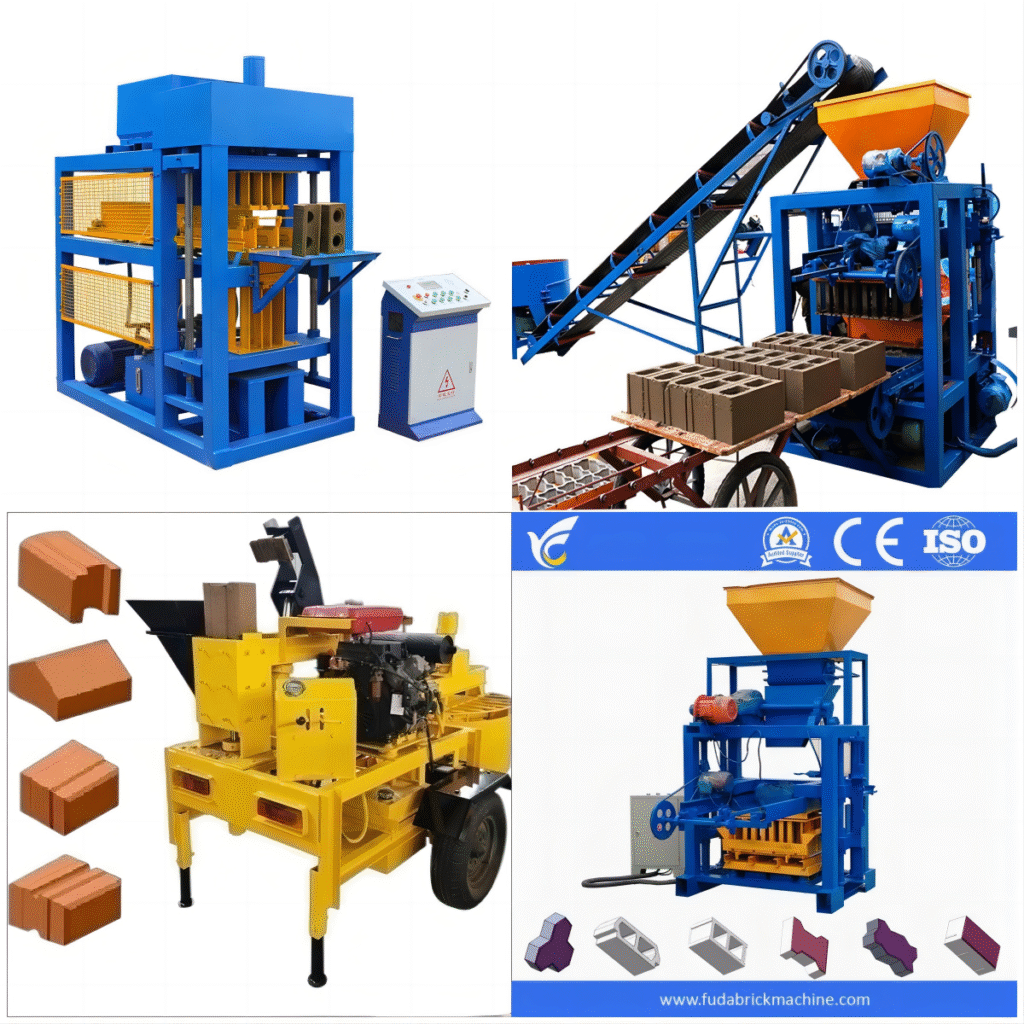

Cement brick making machines are categorized based on their operation mode and level of automation, each suited to different production scales and investment levels.

- Máquinas Completamente Automáticas: These represent the pinnacle of production efficiency. They integrate all stages—batching, mixing, molding, compaction, and palletizing—into a single, continuous, computer-controlled process. Equipped with Programmable Logic Controllers (PLCs) and sophisticated hydraulic systems, they require minimal human intervention and can operate 24/7. They are ideal for large-scale industrial production, major construction projects, and markets with extremely high demand.

- Máquinas Semiautomáticas: This type strikes a balance between output and investment. While the core compaction and molding processes are automated, certain tasks like raw material feeding or brick removal and stacking may require manual labor. They offer high production capacity and consistent quality at a lower capital cost than fully automatic systems, making them a popular choice for medium-sized enterprises.

- Máquinas Manuales o Ponedoras de Huevos: These are mobile, simple, and cost-effective units. An operator manually fills the mold, and the machine uses a lever or a small hydraulic mechanism to apply pressure. The machine is then moved, “laying” the brick directly on the ground for natural curing. While labor-intensive and lower in output, they offer unparalleled flexibility and a very low entry cost for small businesses, start-ups, or projects in remote locations.

1.3 Key Technical Specifications and Performance Metrics

For a distributor or purchaser, evaluating a machine based on its technical specifications is crucial. Key metrics include:

- Production Capacity (Bricks per Hour): This is the primary indicator of output. It varies dramatically, from a few hundred bricks per hour for manual machines to over 10,000 for large automatic lines.

- Tiempo de Ciclo: The total time taken to complete one molding cycle, directly influencing production capacity.

- Pressure Force (Tons or MPa): The maximum pressure the machine can exert, which correlates directly with the compressive strength of the final brick product.

- Power Rating (kW): The electrical power consumption of the machine, which impacts operational costs.

- Automation Level (PLC Control): The presence of a PLC system for precision, repeatability, and ease of operation.

- Overall Dimensions and Footprint: The physical space required for the machine and its auxiliary systems.

- Versatilidad de Materias Primas: The ability to produce different products (solid, hollow, paving blocks, interlocking bricks) by simply changing the mold.

1.4 Strategic Advantages for Business and Construction

Investing in modern cement brick production technology offers a multitude of benefits:

- Exceptional Production Efficiency and Scalability: Automation drastically increases output while reducing the time per production cycle, allowing businesses to scale operations to meet large orders and tight deadlines.

- Superior and Consistent Product Quality: Machine-made bricks exhibit uniform dimensions, high density, and consistent compressive strength, which are critical for structural integrity and compliance with building codes.

- Significant Reduction in Labor Costs: Automated systems minimize the reliance on a large workforce for strenuous tasks, leading to substantial long-term savings and reduced management overhead.

- Enhanced Cost-Effectiveness on Raw Materials: These machines can efficiently use locally available raw materials, including certain industrial by-products like fly ash, reducing material costs and promoting sustainable practices.

- Operational Flexibility and Product Diversification: With interchangeable molds, a single machine can produce a wide array of brick types and styles, enabling a business to diversify its product portfolio and adapt to changing market trends without major capital reinvestment.

1.5 Critical Selection Criteria for Commercial Buyers

When procuring machinery for resale or own use, several factors must be meticulously evaluated:

- Assessing Target Market Demand: The choice of machine must align with the local market’s volume requirements, preferred brick types, and quality standards.

- Financial Analysis: Capital vs. Operational Expenditure: A fully automatic machine has a high initial cost but low running costs. A manual machine has a low entry price but higher per-unit labor costs. A thorough cost-benefit analysis is essential.

- Evaluation of After-Sales Support and Service: The availability of spare parts, technical support, and maintenance services from the supplier is a critical, often overlooked, factor that ensures long-term machine uptime and productivity.

- Supplier Verification and Compliance: It is imperative to partner with reputable suppliers who can provide certifications, comply with international safety standards, and offer reliable warranties.

Conclusión

The cement brick making machine is more than just a piece of industrial equipment; it is a pivotal asset that defines the productivity, quality, and profitability of a construction materials business. The transition from manual to automated production is a strategic move that yields dividends in the form of higher output, superior product consistency, and reduced operational expenses. For distributors and procurement specialists, a deep and nuanced understanding of the different machine types, their technical capabilities, and the associated commercial dynamics is not merely beneficial—it is a fundamental requirement for success. By prioritizing robust machinery that aligns with specific market needs and is backed by strong technical support, businesses can secure a formidable competitive edge in the dynamic global construction market.

Frequently Asked Questions (FAQ)

Q1: What is the fundamental difference between a fully automatic and a semi-automatic machine?

A: A fully automatic machine is an integrated system where all processes, from feeding raw materials to stacking finished bricks, are performed by the machine with minimal operator input, controlled by a PLC. A semi-automatic machine automates the core molding and compaction processes but requires manual intervention for tasks like feeding the mixture or removing and stacking the cured bricks.

Q2: Can one machine produce different types and sizes of bricks?

A: Yes, most modern machines are designed with this flexibility in mind. By changing the mold (also called a die), the same machine can typically produce a variety of products, including solid blocks, hollow blocks, paving stones, and interlocking bricks of different dimensions.

Q3: What are the primary cost factors to consider beyond the initial purchase price?

A: The total cost of ownership includes:

- Operating Costs: Electricity and water consumption.

- Costos Laborales: Wages for operators and maintenance staff.

- Maintenance and Spare Parts: Regular servicing and replacement of wear parts like molds and hydraulic seals.

- Costos de Materias Primas: The ongoing expense of cement, aggregates, and other additives.

- Land and Infrastructure: The cost of the factory space and foundation required for the machine.

Q4: How important is the pressure force specification?

A: Extremely important. The pressure force, measured in tons, directly determines the final brick’s density and compressive strength. Higher pressure results in a denser, stronger, and more durable brick that can meet higher structural grading standards.

Q5: What kind of after-sales service should a reliable supplier offer?

A: A dependable supplier should provide:

- Comprehensive installation and commissioning services.

- On-site or remote operator training.

- Ready availability of genuine spare parts.

- Access to technical support for troubleshooting.

- A clear and responsive warranty policy.

Q6: Are these machines suitable for export to different international markets?

A: Yes, but it is crucial to ensure the machine complies with the destination country’s voltage standards (e.g., 220V/50Hz or 440V/60Hz), safety regulations, and any local certification requirements. A competent supplier should be able to configure the machine for the target market.